Multi-directional constant-pressure asphalt mixture seepage testing device

A technology of asphalt mixture and testing device, which is applied in the direction of measuring device, analysis material, permeability/surface area analysis, etc., can solve the problem of inability to simulate infiltration, inability to achieve constant infiltration water pressure, and impossibility of directional seepage in asphalt mixture Research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

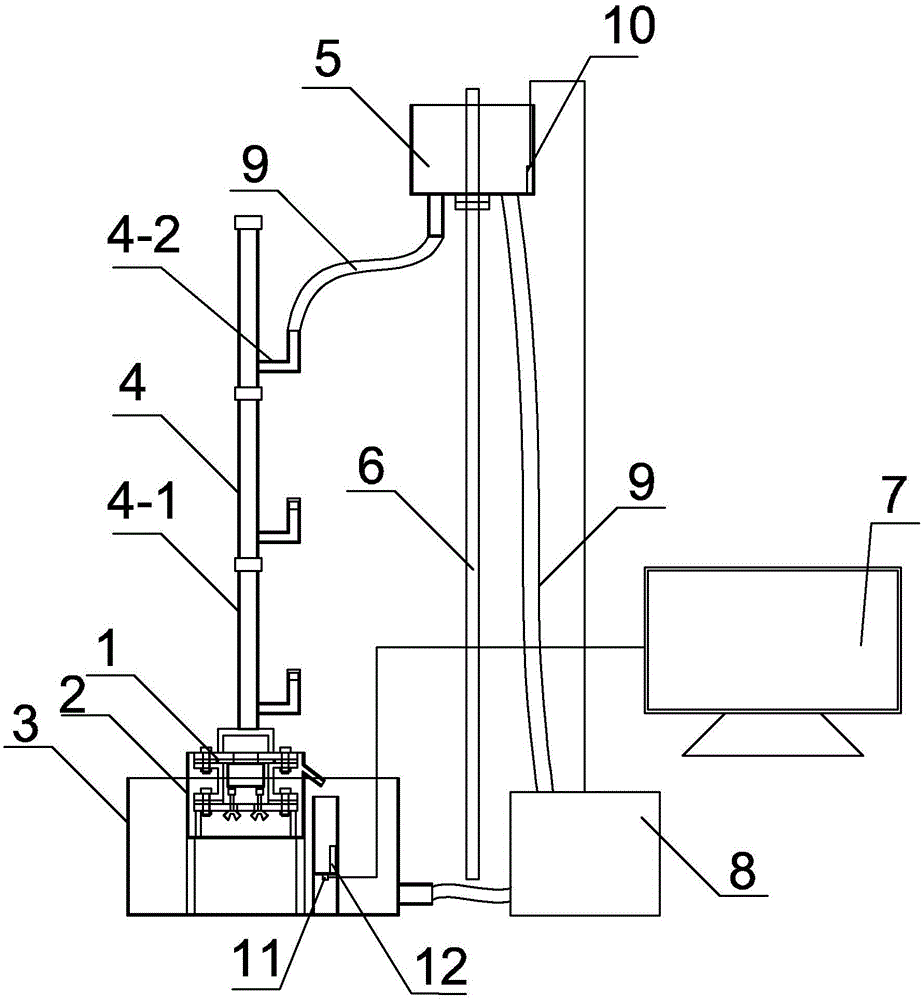

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment, the asphalt mixture multi-directional constant pressure seepage test device described in this embodiment, it includes a water seepage mechanism 1, a water seepage mechanism placement tank 2, a water receiving tank 3, a hydraulic pipe assembly 4, a water tank 5, a water tank bracket 6, Computer control element 7, peristaltic pump 8, first water level measuring sensor 10, measuring cylinder 11, second water level measuring sensor 12 and two silicone hoses 9, water seepage mechanism 1 is arranged in water seepage mechanism placement tank 2, water seepage mechanism placement tank 2 and the measuring cylinder 11 are all arranged in the water receiving tank 3, the side wall of the water seepage mechanism placing tank 2 is provided with a placing tank outlet pipe, and the water outlet end of the placing tank outlet pipe is arranged above the water inlet of the measuring cylinder 11, the water outlet of...

specific Embodiment approach 2

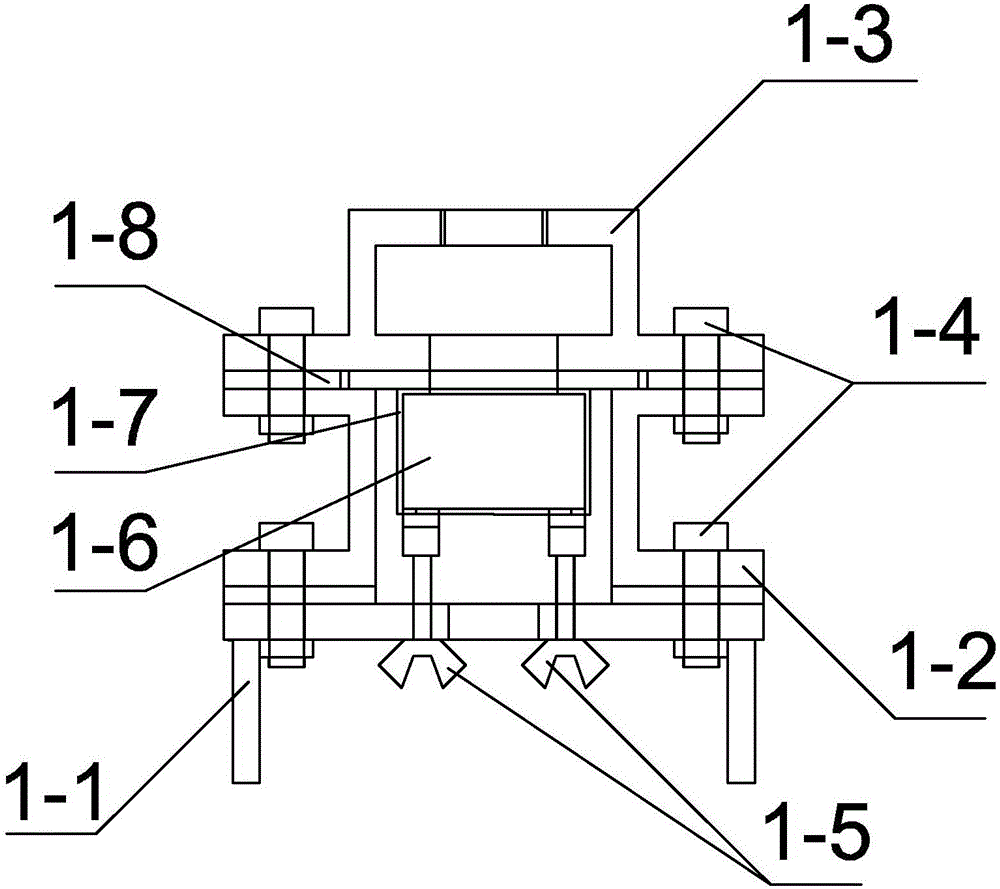

[0013] Specific implementation mode two: combination figure 1 Describe this embodiment, the asphalt mixture multi-directional constant pressure seepage test device described in this embodiment, the water seepage mechanism 1 includes a base 1-1, a fixed connector 1-2, a hydraulic pipe connector 1-3, a rubber seal Set 1-7, two rubber washers 1-8, multiple connecting bolts 1-4 and bolt tightening assembly 1-5, the fixed connecting piece 1-2 includes a circular cylinder and two flanges, the circular cylinder Set vertically, one flange is fixedly installed on the top of the circular cylinder, the other flange is installed on the bottom of the circular cylinder, and the flange at the bottom of the circular cylinder is connected to the base through multiple connecting bolts 1-4 1-1 fixed connection, the flange at the top of the circular cylinder is fixedly connected with the hydraulic pipe connector 1-3 through a plurality of connecting bolts 1-4, and the flange at the bottom of the ...

specific Embodiment approach 3

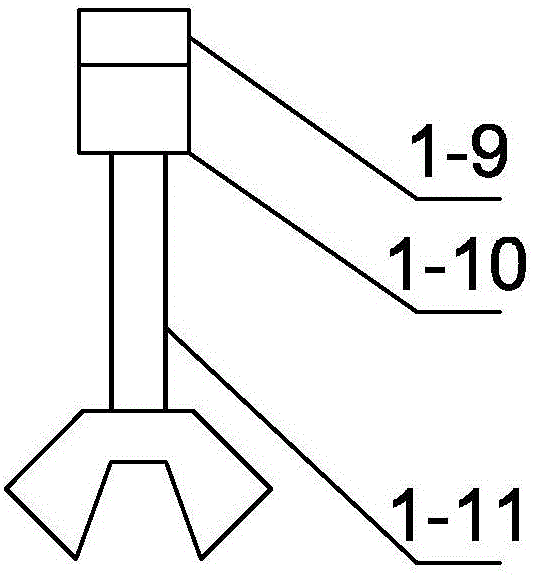

[0014] Specific implementation mode three: combination figure 1 Describe this embodiment, the asphalt mixture multidirectional constant pressure seepage test device described in this embodiment, the bolt tightening assembly 1-5 includes a plurality of plexiglass pads 1-9, a plurality of rubber pads 1-10 and A plurality of first tightening bolts 1-11, the plurality of first tightening bolts 1-11 are installed on the seat plate of the base 1-1 in the circumferential direction, and the threaded end of each first tightening bolt 1-11 is arranged on the base Above the seat plate of 1-1, the screw head of each first tightening bolt 1-11 is set under the seat plate of the base 1-1, and the top of each first tightening bolt 1-11 is arranged in sequence from bottom to top. There is a plexiglass spacer 1-9 and a rubber spacer 1-10, the top of each rubber spacer 1-10 rests on the rubber sealing sleeve 1-7 below the asphalt test piece 1-6, other components and connections The relationshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com