Rotary transformer test clamping device

A resolver and clamping technology, which is applied in the direction of measuring devices, measuring device shells, instruments, etc., can solve problems such as inaccurate positioning, testing, and affecting product performance, and achieve rapid manufacturing and replacement and meet high-precision requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

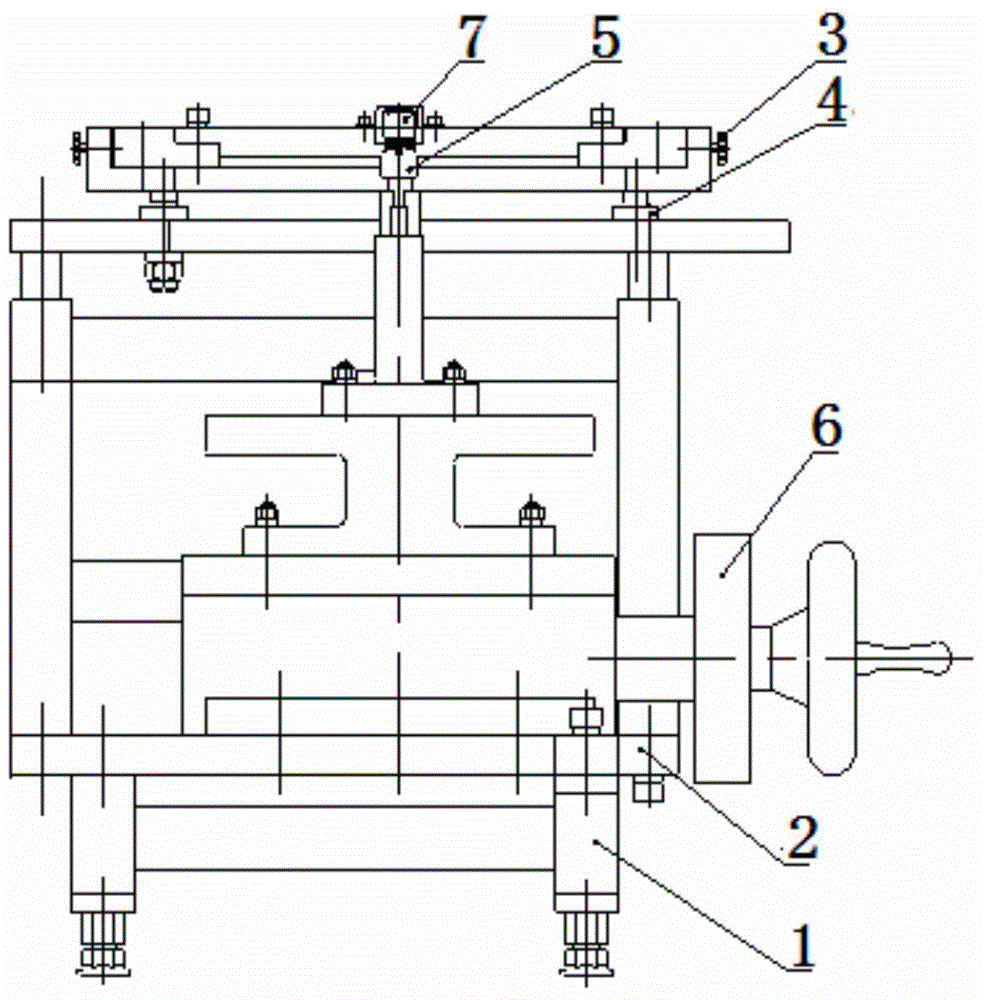

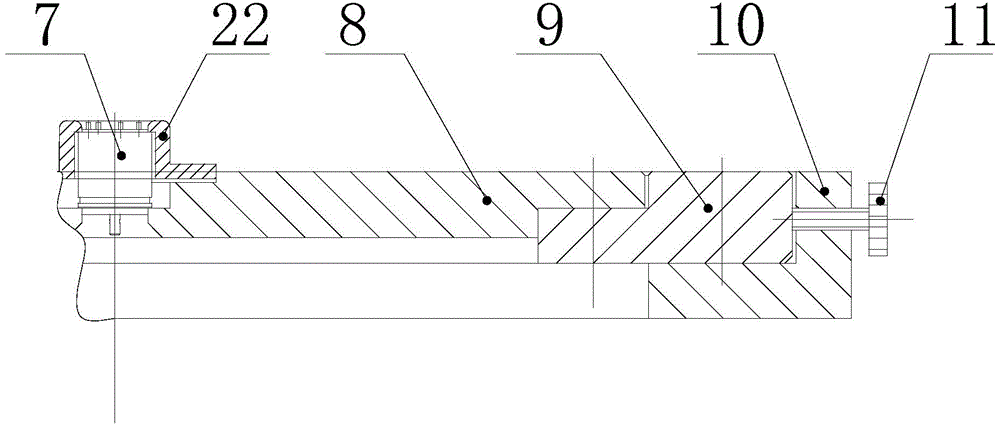

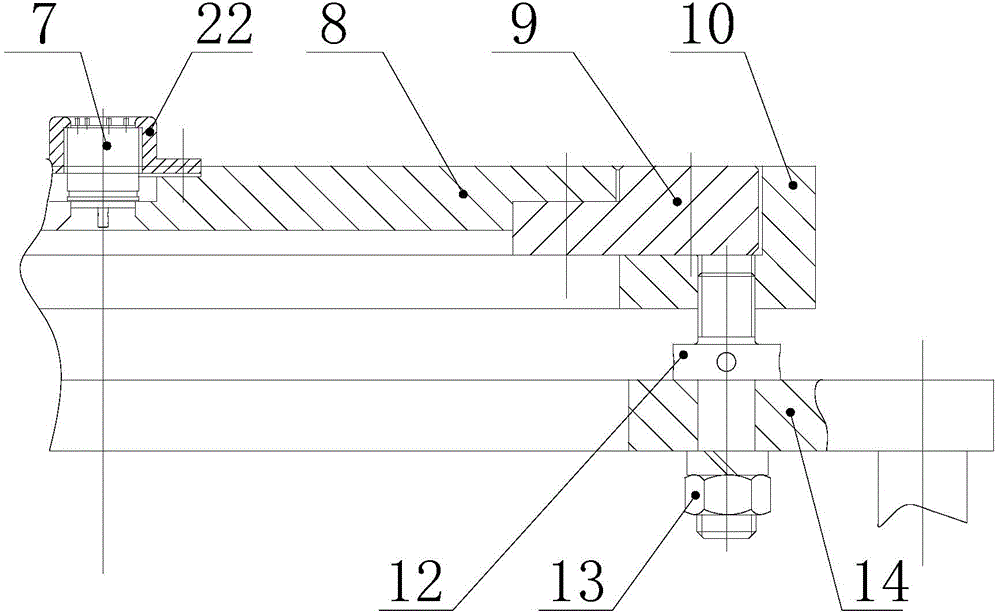

[0017] The resolver test and clamping equipment is composed as follows: a support 1, a base 2, a horizontal radial adjustment mechanism 3, a vertical axial adjustment mechanism 4, a rotor positioning mechanism 5, and a fine-tuning rotation mechanism 6; the base 2 is located on the support 1 Above, the base 2 is connected with the fine-tuning rotating mechanism 6, the rotor positioning mechanism 5 is connected with the fine-tuning rotating mechanism 6, the horizontal radial adjustment mechanism 3 is connected with the vertical axial adjustment mechanism 4 through the outer flange 10, and the vertical axial The adjustment mechanism 4 is connected with the support 1, and the casing of the resolver 7 is fixed on the positioning flange 8 through a gland and screws. The positioning flange 8, the middle flange 9, the outer flange 10 and the adjustment screw I11 form a horizontal radial adjustment mechanism 3; the positioning flange 8 is connected with the outer flange 10 through the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com