A liquid-cooled hub motor and motor vehicle

An in-wheel motor, liquid cooling technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of high damage risk, large environmental impact, unstable sealing ring effect of liquid cooling system, etc., to reduce loss and thermal expansion. Influence reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

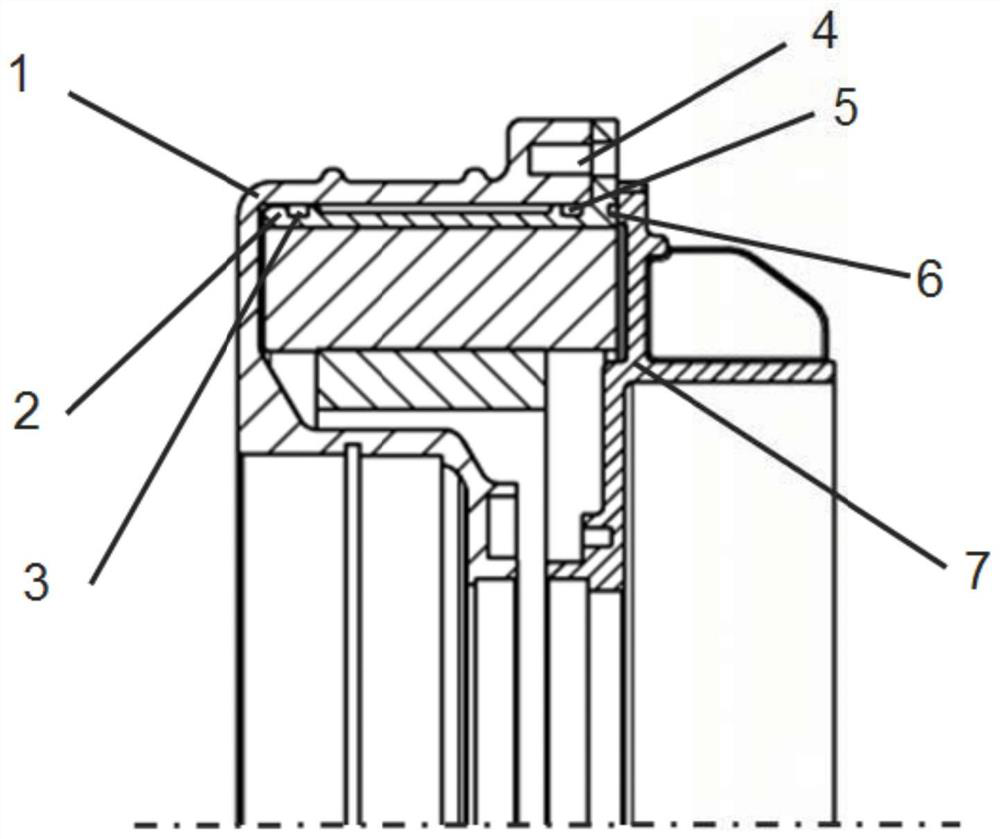

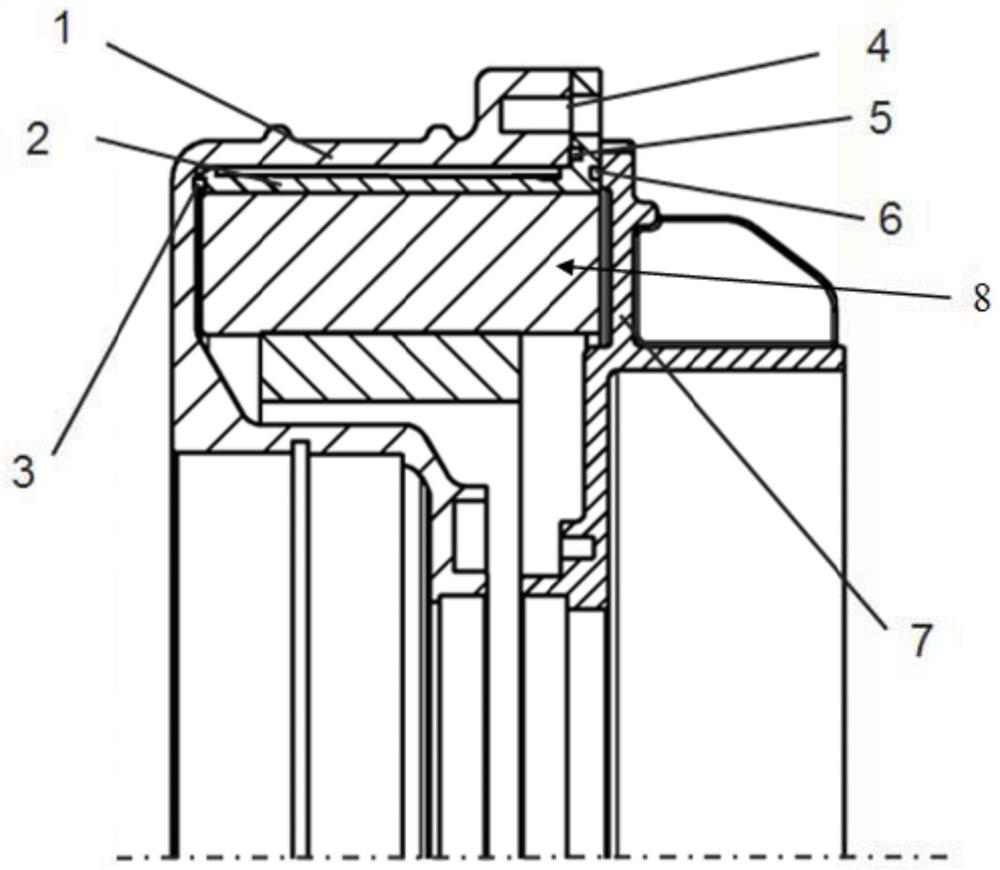

[0024] The first embodiment of the present invention is as figure 2 and image 3 shown.

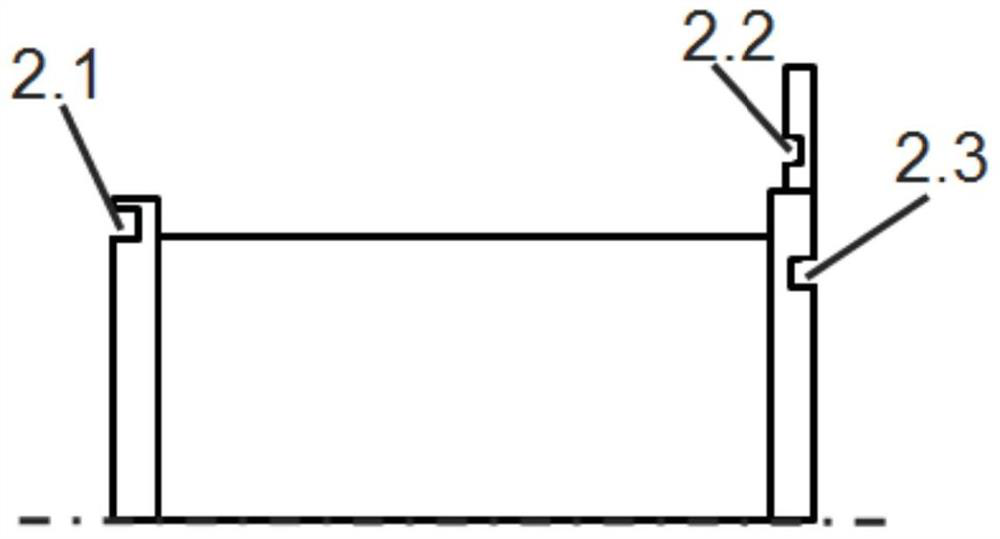

[0025] Such as figure 2 As shown, the liquid-cooled hub motor of the present invention includes a housing 1, a cooling liquid jacket 2 with a radially protruding fixed part arranged in the housing, a motor 8 arranged inside the cooling liquid jacket 2, and a motor 8 arranged on the inside of the casing. The first sealing ring 3 and the second sealing ring 5 between the housing 1 and the cooling liquid jacket 2, and the bolts 4 for axially tightening the fixing part to fix the cooling liquid jacket 2 and the housing 1 , the cover plate 7 arranged on the axial side of the housing 1 and the cooling liquid jacket 2 and fixed with the housing 1 by bolts, and the circumferential direction between the cooling liquid jacket 2 and the cover plate 7 The third sealing ring 6. The first sealing ring 3 is arranged on the innermost side of the cooling liquid jacket 2 (the leftmost side in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com