Prism-coupling systems and methods for characterizing curved parts

A curved, prism technology, applied in the field of prism coupling system, can solve problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to the various embodiments of the present disclosure, examples of which are illustrated in the accompanying drawings. Wherever possible, the same or like reference numerals will be used throughout the drawings to refer to the same or like parts. The figures are not necessarily drawn to scale, and one skilled in the art recognizes where the figures have been simplified to illustrate key aspects of the disclosure.

[0034] The claims set forth below are incorporated into and constitute a part of this Detailed Description.

[0035] The entire disclosure of any publication or patent document mentioned herein is hereby incorporated by reference, including US patent applications S / N 13 / 463,322 and 61 / 706,891.

[0036] curved parts

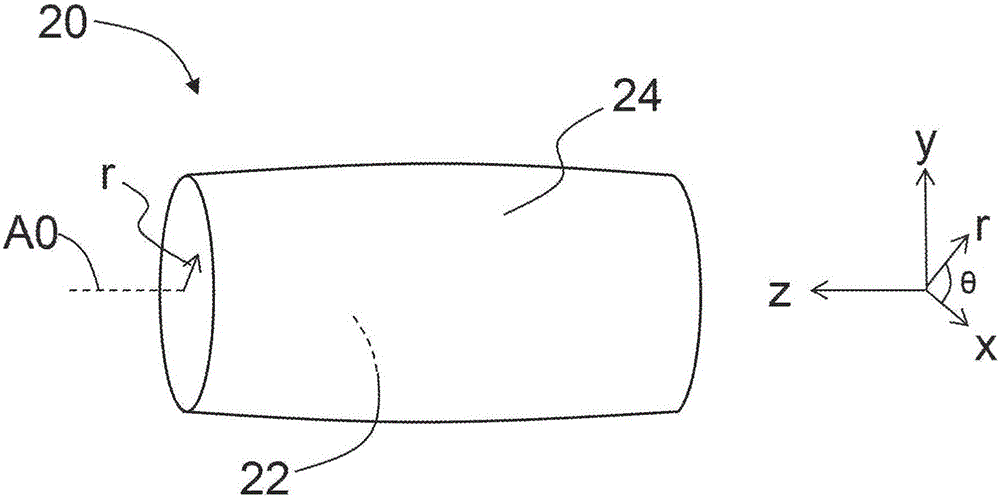

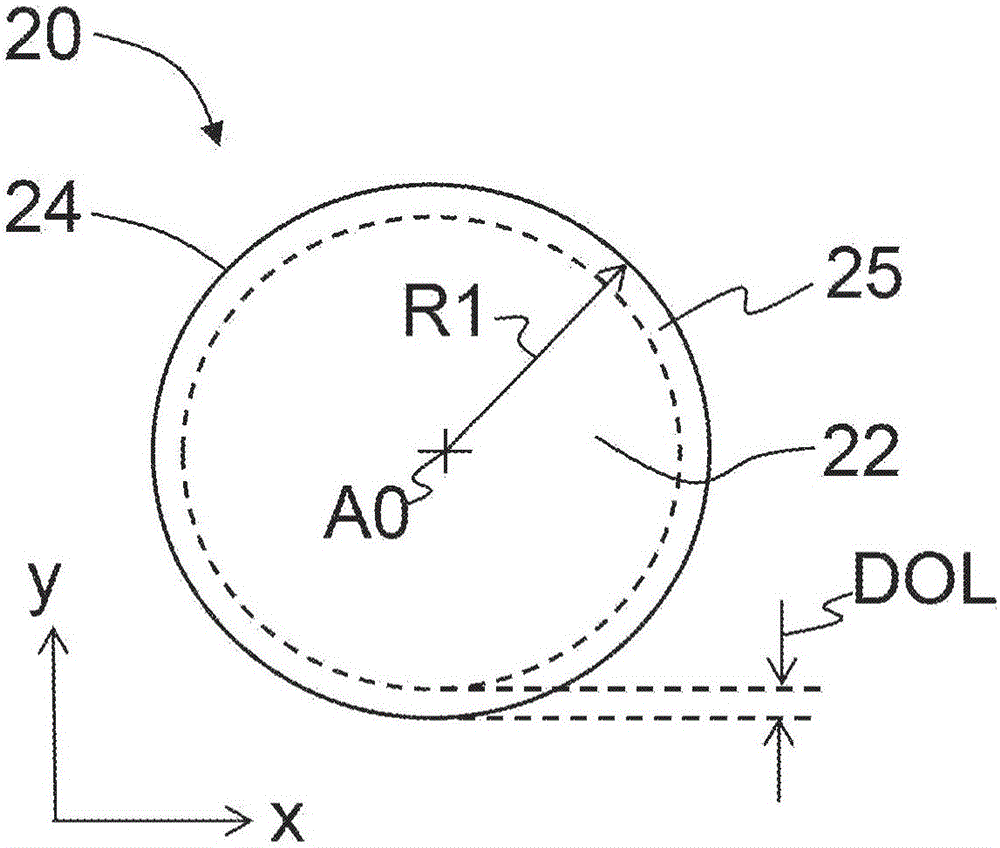

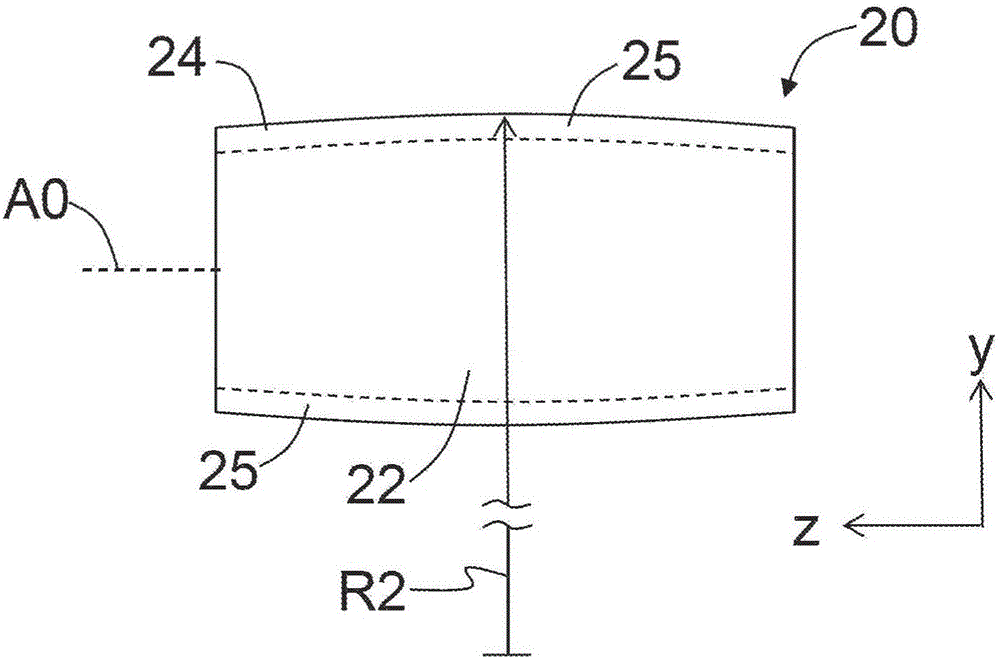

[0037] Figure 1A is an isometric view of an example curved part 20, and Figure 1Bis a cross-sectional view of the curved part taken in the x-y plane. The curved part 20 has a main body 22 and a curved out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com