Printing device for optical fiber cable sheath

A fiber optic cable and sheath technology, applied in the field of printing devices for fiber optic cable sheaths, can solve the problems of crushed product quality, thinning of the sheath at the embossed place, accidents, etc., to ensure product quality, complete printing content, Good effect of tightening the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

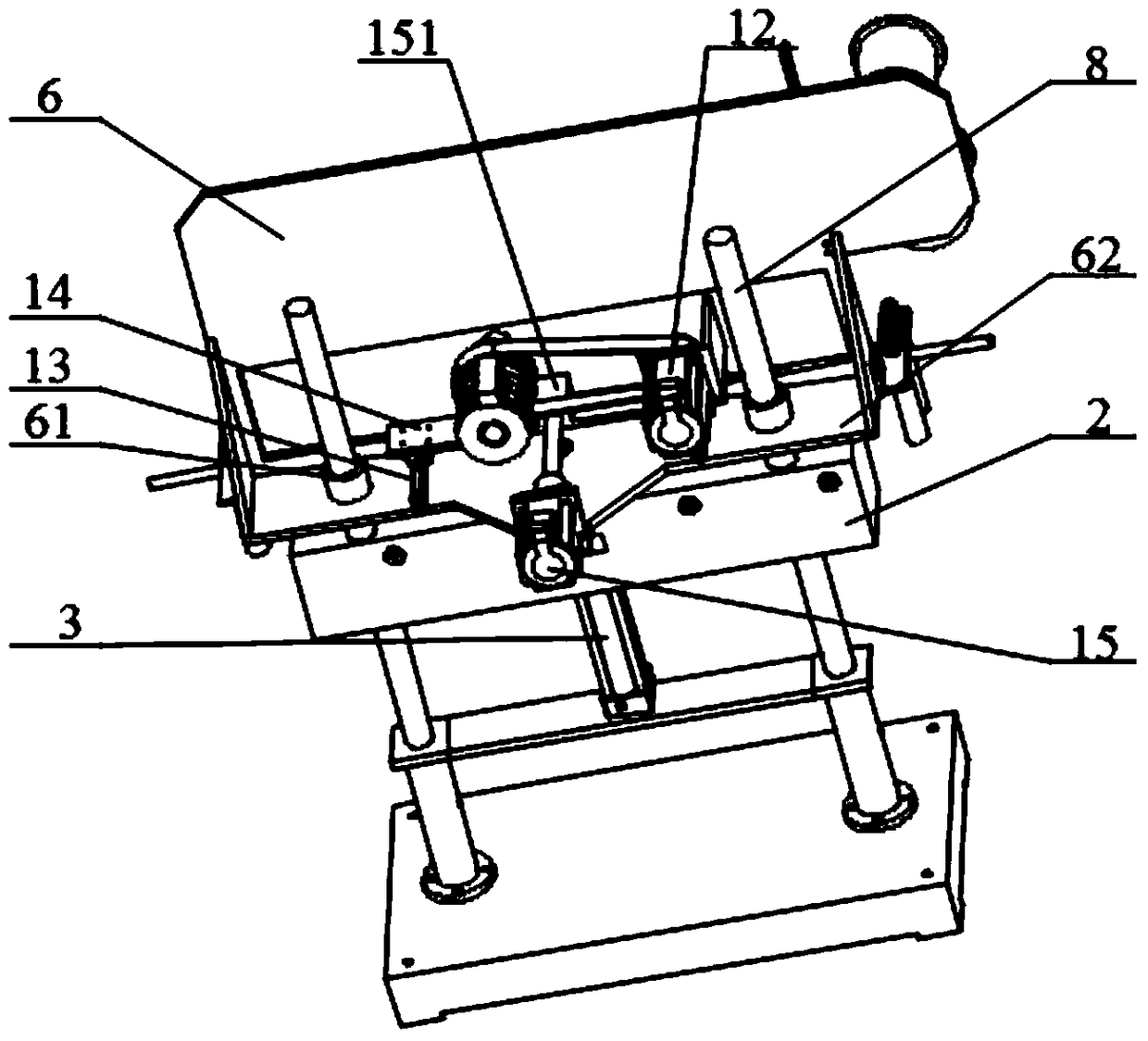

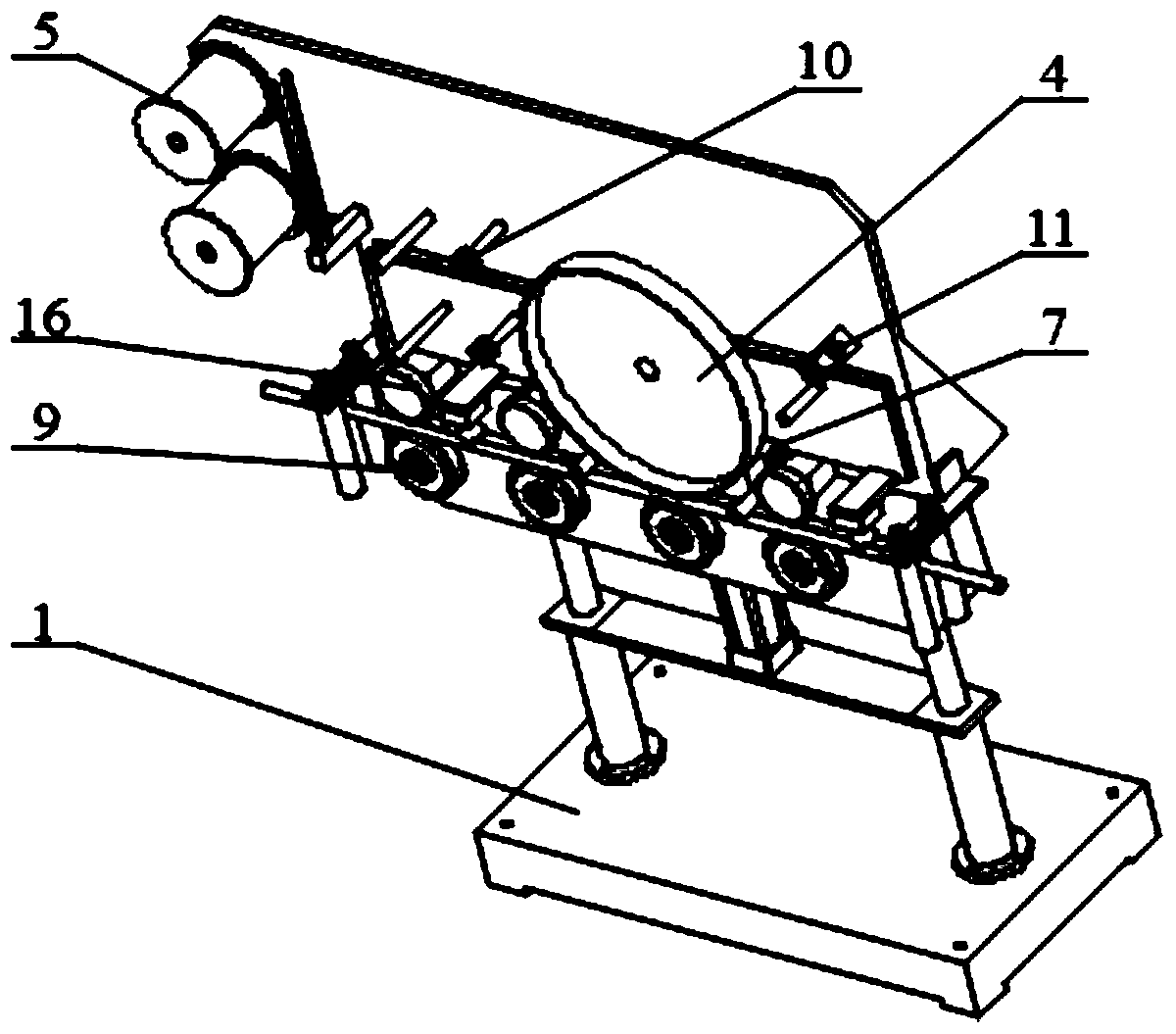

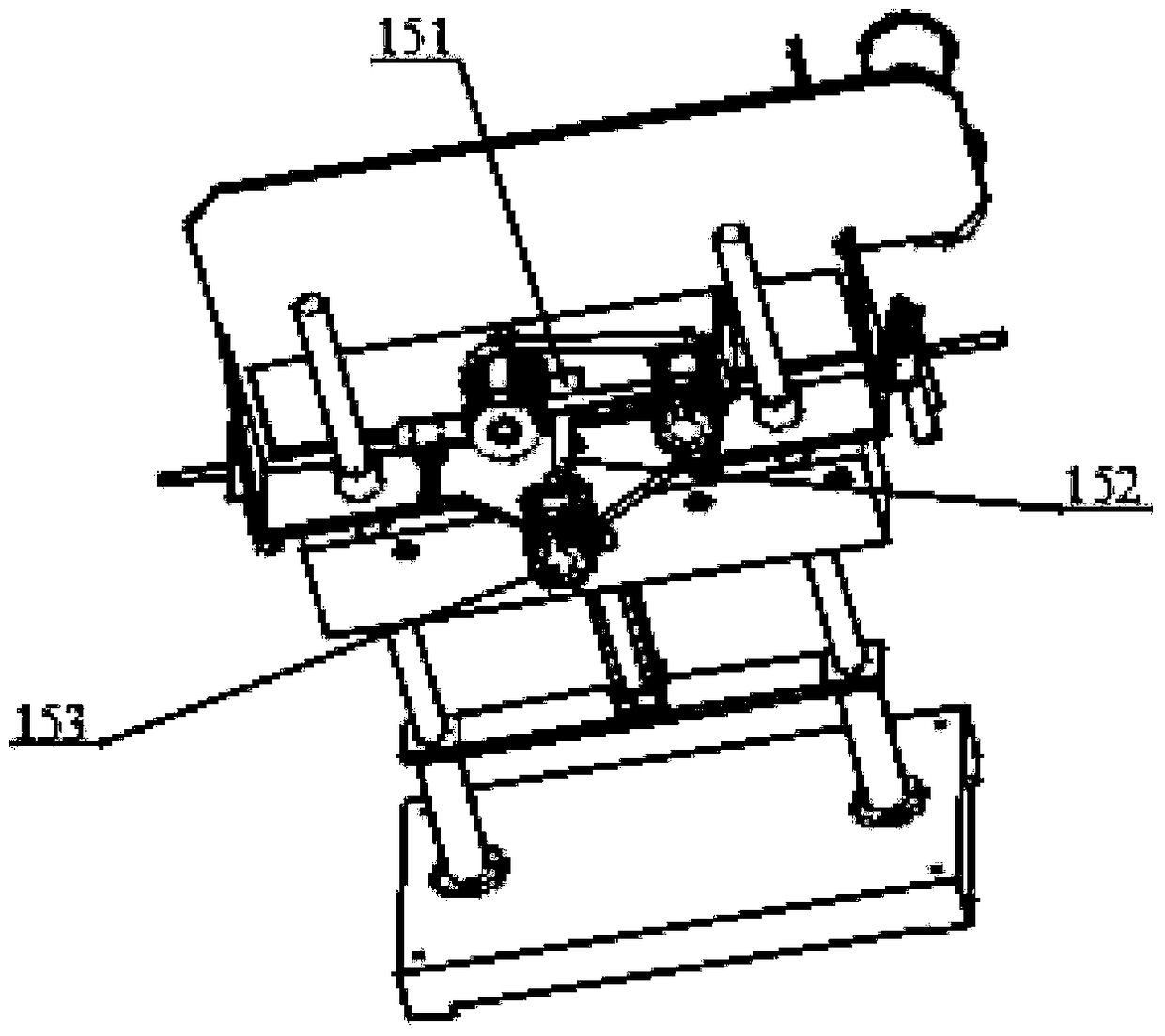

[0021] Embodiment 1: A printing device for an optical fiber cable sheath, including: a base 1, a fixed seat 2, a tension adjustment cylinder 3, a heat embossing wheel 4, a ribbon installation disc 5 wrapped with a ribbon, a lifting plate 6, and a translation plate 7. Two left and right guide shafts 8 are fixed on the upper surface of the base 1. The fixed base 2 is fixed in the middle of the two guide shafts 8. The front side of the fixed base 2 is provided with several supports along the horizontal direction. The fixed wheel 9, the lifting plate 6 has two guide sleeves 61 arranged left and right, the guide shaft 8 above the fixed seat 2 is embedded in the guide sleeve 61 of the lifting plate 6;

[0022] The ribbon mounting disc 5 is installed on the front surface of the lifting plate 6, and a guide wheel 10 fixed to the lifting plate 6 or the flat plate 7 is arranged between the ribbon mounting disc 5 and the hot embossing wheel 4. An air duct 11 for absorbing the ribbon is f...

Embodiment 2

[0027]Embodiment 2: A printing device for an optical fiber cable sheath, including: a base 1, a fixed seat 2, a tension adjustment cylinder 3, a heat embossing wheel 4, a ribbon installation disc 5 wrapped with a ribbon, a lifting plate 6, and a translation plate 7. Two left and right guide shafts 8 are fixed on the upper surface of the base 1. The fixed base 2 is fixed in the middle of the two guide shafts 8. The front side of the fixed base 2 is provided with several supports along the horizontal direction. The fixed wheel 9, the lifting plate 6 has two guide sleeves 61 arranged left and right, the guide shaft 8 above the fixed seat 2 is embedded in the guide sleeve 61 of the lifting plate 6;

[0028] The ribbon mounting disc 5 is installed on the front surface of the lifting plate 6, and a guide wheel 10 fixed to the lifting plate 6 or the flat plate 7 is arranged between the ribbon mounting disc 5 and the hot embossing wheel 4. An air duct 11 for absorbing the ribbon is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com