Neatening, punching and binding all-in-one machine for finance forms and using method of neatening, punching and binding all-in-one machine

An all-in-one machine and form technology, applied in bookbinding, folders, printing, etc., can solve the problems of no special equipment, poor effect, low efficiency, etc., and achieve high binding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

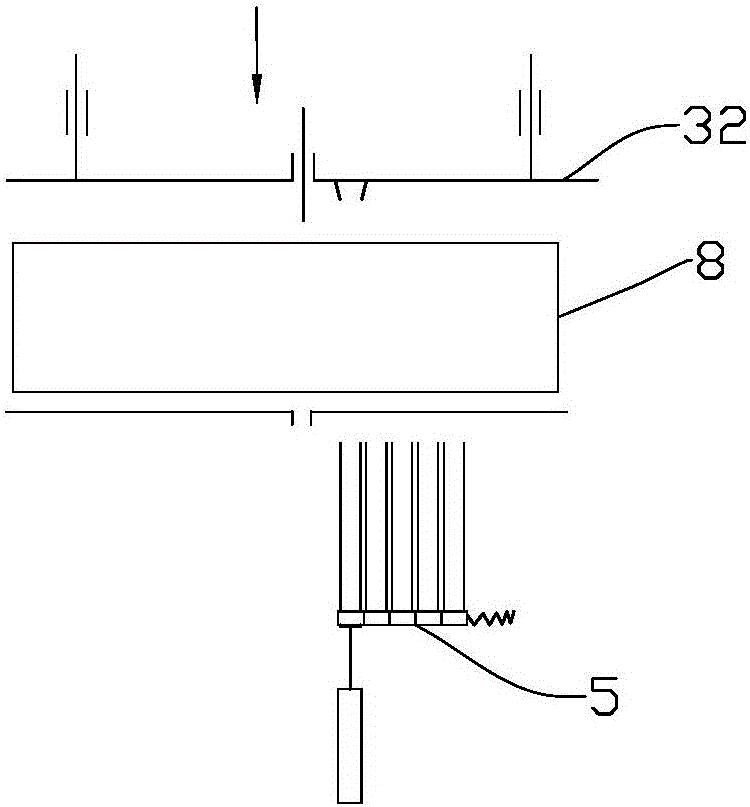

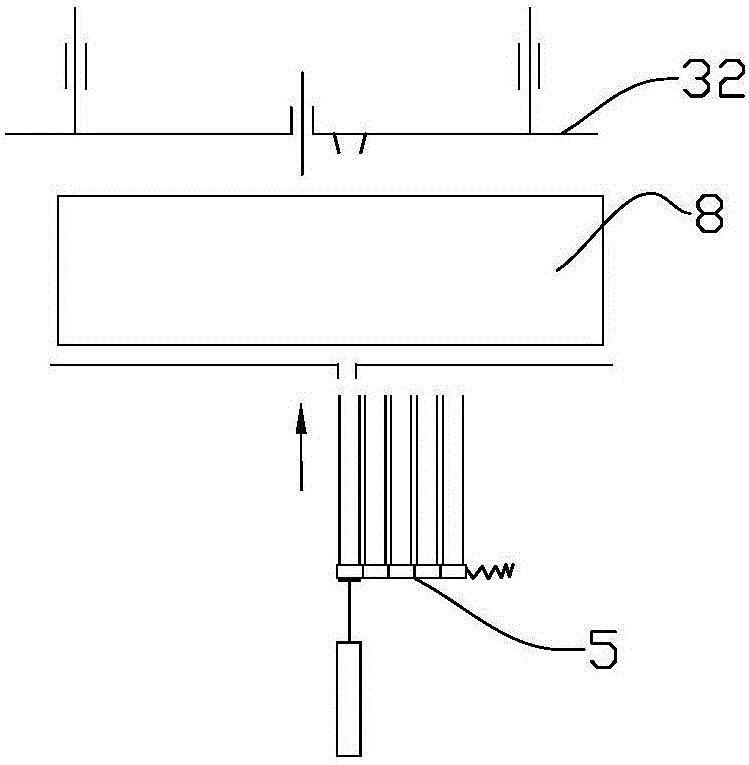

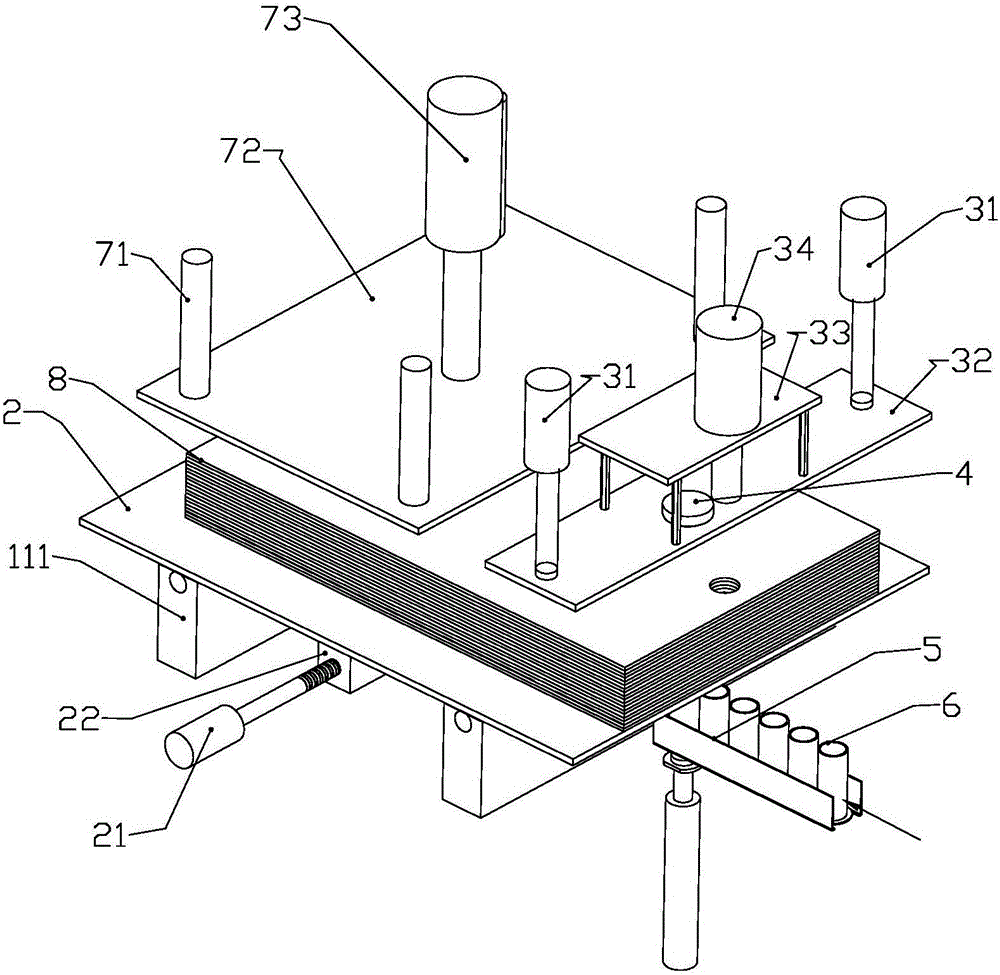

[0038] Such as Figure 1 to Figure 10 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0039] What is developed is an all-in-one machine for sorting, punching and binding forms. Its basic principle is to compact through the compacting mechanism, realize rapid sorting under the action of heat assistance, and then carry out the finishing process under the action of the punching mechanism. Fast punching, and a shredded paper cleaning system is set in the punching mechanism to prevent the punching tool from being blocked, and finally move to the binding station, and complete the threading and binding work through the binding mechanism to complete the work.

[0040] Based on the above description, the following is a detailed description of its structure:

[0041] Bracket 1, the bracket provides the installation foundation for the entire device, including the base 11 and the upper cantilever 12, which are connected by a column to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com