A kind of method of producing isobutene with mto by-product carbon four as raw material

An isobutene and by-product technology, applied in the field of isobutene production, can solve the problems of low isobutene single-pass yield and accelerated catalyst deactivation, and achieve the effects of high single-pass yield, low cost and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

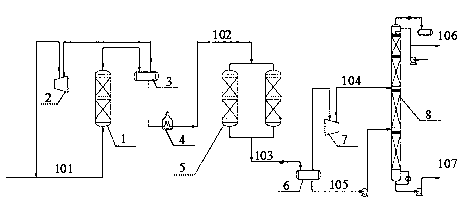

Image

Examples

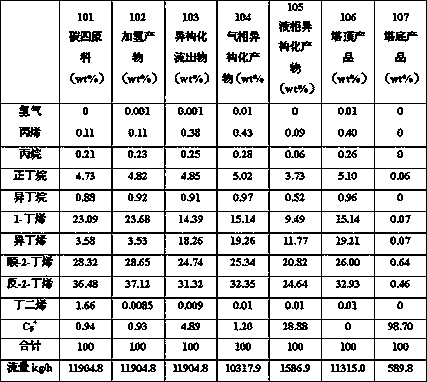

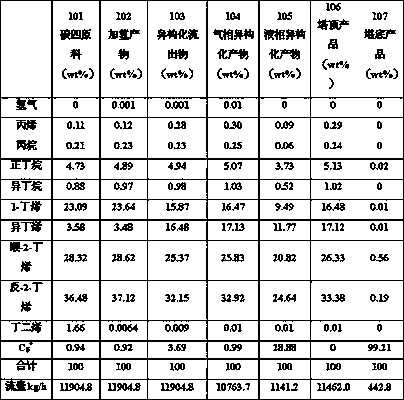

Embodiment 1

[0033] (1) The operating pressure of the hydrogenation reactor is 2.0 MPa, the operating temperature is 65°C, and the space velocity is 5 h -1 , H 2 The / butadiene molar ratio is 2.0, the diameter of the reactor is 1200mm, and the height is 3600mm. It is filled with two stages of amorphous nickel phosphide catalysts, a total of 3.9m 3 . Catalyst composition: Ni loading is based on the weight percentage of Ni metal weight in the total catalyst weight, P content and Ce content are expressed by P / Ni, Ce / Ni molar ratio respectively, Ni content is 10.12%, P / Ni=2.35, Ce / Ni Ni=0.01. Catalyst specific surface area 276 m 2 / g, pressure test strength ≮60 N / cm. The preparation process of the catalyst is as follows: 1) Weigh 49.5 grams of nickel nitrate and add 500 ml of deionized water, then add 0.05 mol / L nitric acid to adjust the pH value to 2-3, then add metered amounts of diammonium hydrogen phosphate, cerium nitrate and citric acid (CA), make P / Ni=2.5, Ce / Ni=0.01, CA / Ni=1 in th...

Embodiment 2

[0041] (1) The operating pressure of the hydrogenation reactor is 2.0 MPa, the operating temperature is 95°C, and the space velocity is 5 h -1 , H 2 The / butadiene molar ratio is 1.5, the diameter of the reactor is 1200mm, and the height is 3600mm. It is filled with two stages of amorphous nickel phosphide catalyst, a total of 3.9m 3 . Catalyst composition: Ni loading is based on the weight percentage of Ni metal weight in the total catalyst weight, P content and Ce content are expressed by P / Ni, Ce / Ni molar ratio respectively, Ni content is 14.96%, P / Ni=2.06, Ce / Ni Ni=0.03. Catalyst specific surface area 245 m 2 / g, pressure test strength ≮60 N / cm. The preparation process of the catalyst is as follows: 1) Weigh 74.3 grams of nickel nitrate and add 500 ml of deionized water, then add 0.05 mol / L nitric acid to adjust the pH value to 2-3, and then add metered amounts of diammonium hydrogen phosphate, cerium nitrate and citric acid (CA), make P / Ni=3, Ce / Ni=0.03, CA / Ni=1.5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com