Preparation method of phosphomonoester

A phosphoric acid monoester and temperature control technology, which is applied in chemical instruments and methods, phosphorus organic compounds, compounds of group 5/15 elements of the periodic table, etc., can solve the problem of low content of phosphoric acid monoester and complex preparation process of phosphoric acid monoester, etc. problem, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

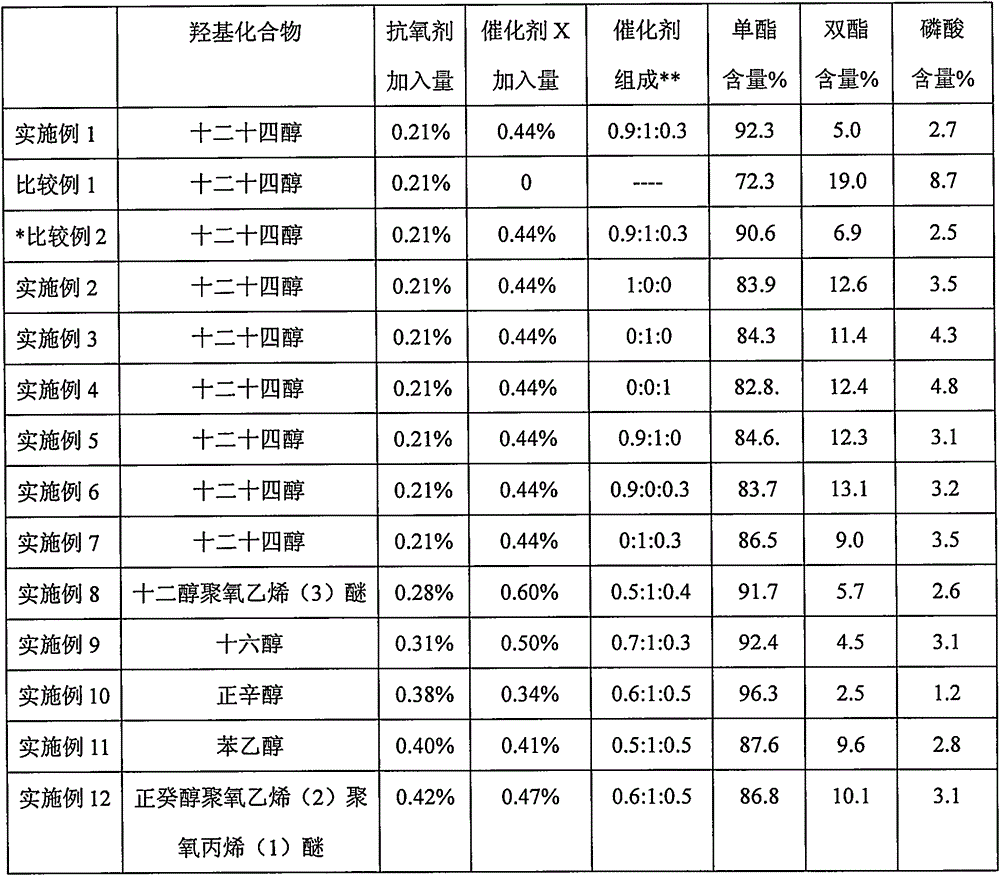

Embodiment 1

[0040] Preparation of Tetradecyl Phosphate Monoester: 200.00 g of tetradecyl mixed alcohol (mass ratio of dodecyl alcohol to tetradecyl alcohol is 70:30), 0.42 g of hypophosphorous acid and pure water are added to a round bottom flask 14.80g, open and stir and heat up; When temperature rises to 70 ℃, add catalyzer (the catalyzer is SnCl 4 , MnO 2 and CuSO 4 Mixture with a mass ratio of 0.9:1:0.3) 0.88g, and then 74.28g of phosphorus pentoxide was added in sections, the temperature was controlled at 75±5°C, and the feeding time was controlled at 1.5 hours; after the addition, it was kept at 85°C for 4.5 hours , and then add 5.18g of pure water, control the temperature to 85°C, keep the temperature at this temperature for 2 hours, then cool down to 75°C and filter to obtain the phosphoric acid ester product. Analysis by double indicator titration method: monoester: 92.3%, diester: 5.0%, phosphoric acid 2.7%.

Embodiment 2

[0048] The difference from Example 1 is that the catalyst is SnCl 4 .

[0049] Add 200.00g of tetradecyl alcohol (mass ratio of dodecanol to tetradecyl alcohol is 70:30), 0.42g of hypophosphorous acid and 14.80g of pure water in the round bottom flask, start stirring and heat up; when the temperature rises to Add 40.88g of SnCl to the round bottom flask at 70°C, then add 74.28g of phosphorus pentoxide in stages, control the temperature at 75±5°C, and control the feeding time for 1.5 hours; Then add 5.18g of pure water, control the temperature at 85±2°C, keep at this temperature for 2 hours, then cool down to 75°C and filter to obtain the phosphate ester product. Analysis by double indicator titration: monoester: 83.9%, diester: 12.6%, phosphoric acid 3.5%.

Embodiment 3

[0051] The difference from Example 1 is that the catalyst is MnO 2 .

[0052] Add 200.00g of tetradecyl alcohol (mass ratio of dodecanol to tetradecyl alcohol is 70:30), 0.42g of hypophosphorous acid and 14.80g of pure water in the round bottom flask, start stirring and heat up; when the temperature rises to Add MnO to the round bottom flask at 70°C 2 0.88g, then 74.28g of phosphorus pentoxide was added in sections, the temperature was controlled at 75±5°C, and the feeding time was controlled at 1.5 hours; 85±2°C, and kept at this temperature for 2 hours, then cooled to 75°C and filtered to obtain the phosphate ester product. Analysis by double indicator titration method: monoester: 84.3%, diester: 11.4%, phosphoric acid 4.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com