A method for bacteria leaching uranium from carbon-silicon mudstone-type uranium ore

A technology of uranium ore and carbon-silicon, which is applied in the field of efficient uranium leaching by bacteria, can solve problems such as the limitation of extensive development and utilization of uranium ore, low grade of uranium in ore, and economic unfeasibility, so as to avoid the use of sulfuric acid and oxidant and achieve high recovery rate of uranium , the effect of expanding resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

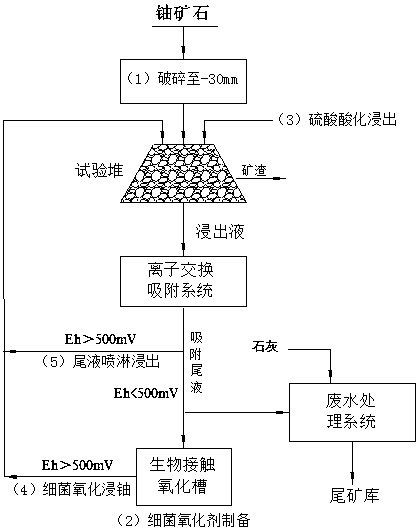

Method used

Image

Examples

Embodiment 1

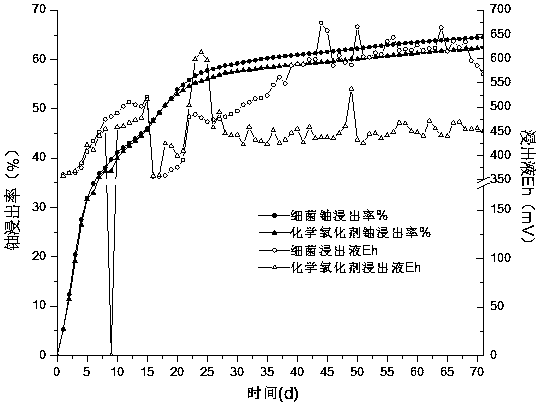

[0032] Test conditions: Using carbon-silicon mudstone-type uranium ore in Xiushui area, Jiujiang City, Jiangxi Province, the comparison test of bacterial leaching and chemical oxidant leaching was carried out. The diameter of the column is 30cm, the height of the column is 120cm, the weight of the ore is 58kg, the particle size of the ore is -30mm, and the grades of the raw ore uranium are respectively are 0.0353% and 0.0328%. The organic carbon content in the ore is 12.57%, Fe 2 o 3 and FeO accounted for 3.94% and 0.252%, respectively.

[0033] Condition control: bacterial leaching: use bacterial oxidant, chemical leaching: add 3% sodium chlorate oxidant after uranium ore is sterilized. Using the steps (1)-(5) of the present invention, a comparative test of uranium immersion is carried out.

[0034] Test results: The uranium leaching time was 71 days, the uranium grades of the two slags were 0.0114% and 0.0134%, the leaching rates of uranium in slag were 67.71% and 59.15%,...

Embodiment 2

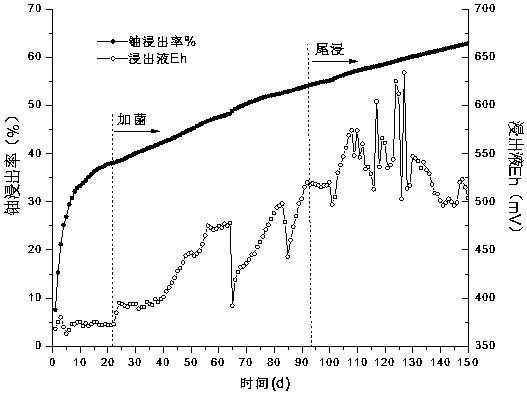

[0036]Test conditions: Use carbon-silicon mudstone-type uranium ore in Xiushui area, Jiujiang City, Jiangxi Province. The diameter of the column is 30cm, the column height is 180cm, the ore weight is 120kg, the ore particle size is -30mm, and the raw ore uranium grade is 0.0252%. The organic carbon content in the ore is 13.10%, Fe 2 o 3 The proportions of FeO and FeO are 4.00% and 0.236%, respectively, and the sulfur content is 1.18%.

[0037] Condition control: adopt steps (1)-(5) of the present invention to carry out bacterial uranium leaching test.

[0038] Test results: The uranium leaching time was 150 days, the uranium grade in slag was 0.00782%, the leaching rate of uranium in slag was 68.97%, and the acid consumption was 0.27%. The curve of uranium leaching rate with time is shown in image 3 , it can be seen from the figure that the uranium leaching rate is faster in the early stage of acid leaching. This is because the hexavalent uranium in the ore is quickly leac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com