Mask plate, evaporation device and evaporation method

A mask plate and evaporation technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of color mixing, large gap between the metal mask and the substrate, and achieve the effect of reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

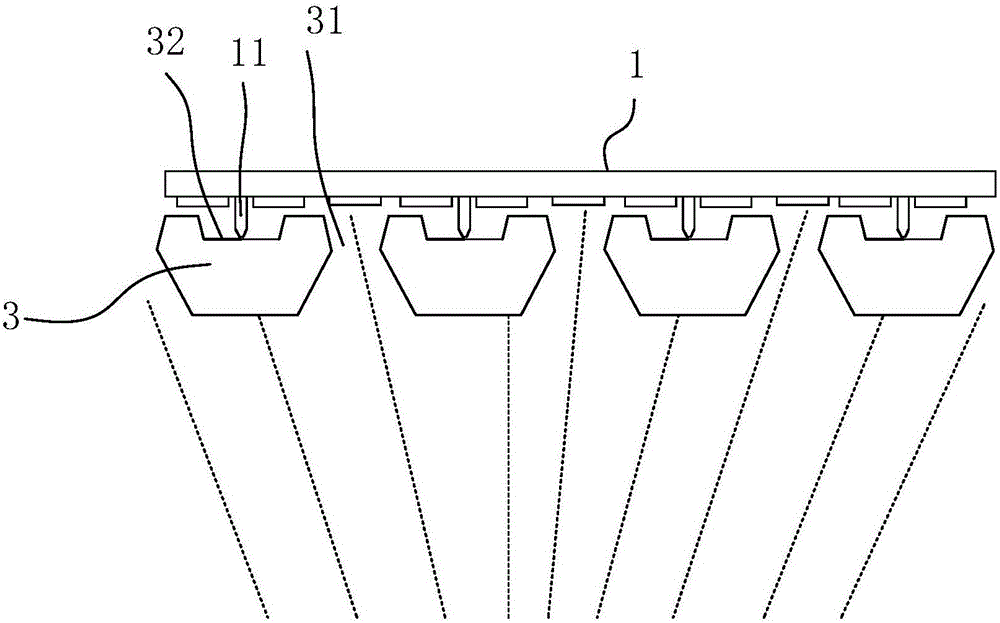

[0030] See figure 2 The mask includes a mask body 3, the mask body is provided with a through hole 31, and the upper end surface of the mask body is provided with a groove 32 for accommodating the photoresist isolation column on the surface of the substrate.

[0031] In this embodiment, the cross section of the groove 32 perpendicular to the direction of the mask body is an inverted trapezoid groove.

[0032] The specific vapor deposition method using the mask includes the following steps:

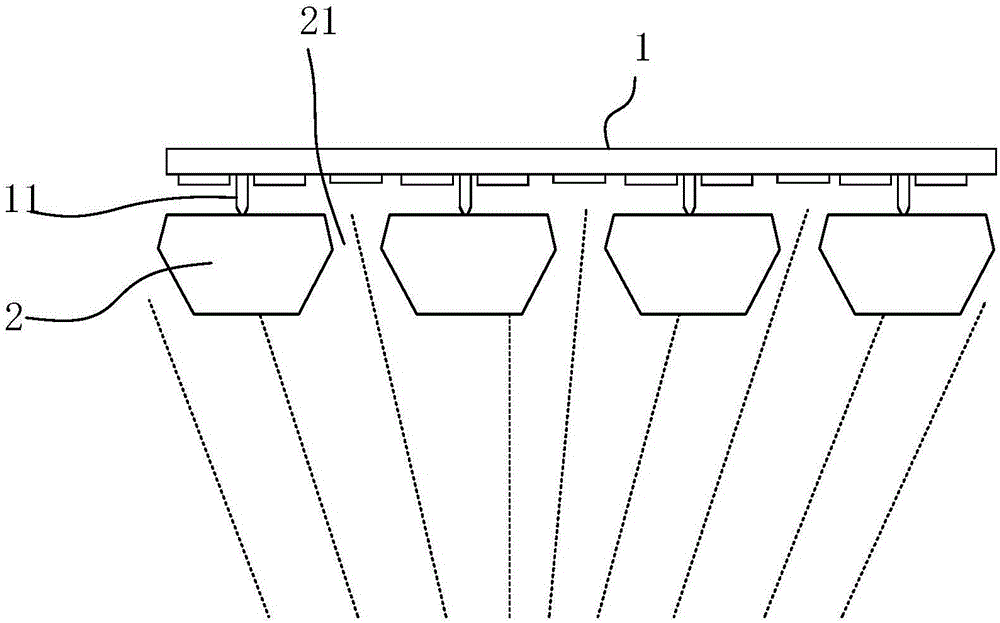

[0033] Provide a substrate 1 to be film-formed, which includes a region to be film-formed and a plurality of photoresist isolation columns 11;

[0034] Providing an evaporation source, the evaporation source and the mask plate are arranged oppositely and fixed in position;

[0035] The substrate 1 to be filmed and the mask body 3 are arranged in parallel and aligned so that the area to be filmed of the substrate 1 corresponds to the through hole 31 of the mask, and the photoresist isolation column ...

Embodiment 2

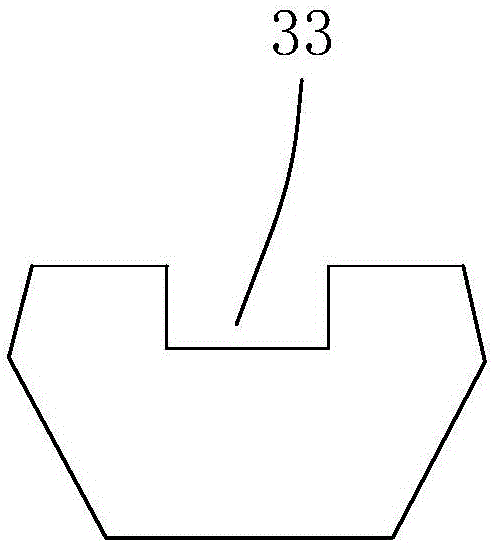

[0037] See image 3 , The mask includes a mask body, the mask body is provided with a through hole, and the upper end surface of the mask body is provided with a groove for containing the photoresist isolation column on the surface of the substrate. In this embodiment, the cross section of the groove 33 perpendicular to the direction of the mask body is square.

[0038] The specific vapor deposition method using the mask includes the following steps:

[0039] The substrate 1 to be filmed and the mask body 3 are arranged in parallel and aligned so that the area to be filmed of the substrate 1 corresponds to the through hole 31 of the mask, and the photoresist isolation column 11 of the substrate 1 corresponds to the mask. The square groove 33; move the substrate 1 to be filmed in the direction perpendicular to the mask body 3, so that the substrate 1 to be filmed is close to the mask to the bottom of the photoresist isolation column 11 inserted into the square groove 33; The platin...

Embodiment 3

[0041] See Figure 4 , The mask includes a mask body, the mask body is provided with a through hole, and the upper end surface of the mask body is provided with a groove for containing the photoresist isolation column on the surface of the substrate. In this embodiment, the cross section of the groove 34 perpendicular to the direction of the mask body is an arc groove.

[0042] The specific vapor deposition method using the mask includes the following steps:

[0043] The substrate 1 to be filmed and the mask body 3 are arranged in parallel and aligned so that the area to be filmed of the substrate 1 corresponds to the through hole 31 of the mask, and the photoresist isolation column 11 of the substrate 1 corresponds to the mask. The arc groove 34; move the substrate 1 to be filmed in the direction perpendicular to the mask body 3, so that the substrate 1 to be filmed is close to the mask to the bottom of the photoresist isolation column 11 inserted into the arc groove 34; The plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com