Oil extraction method for injecting water among well fissures of multistage fractured horizontal well at intervals

A technology for horizontal well and water injection production, which is applied in the fields of fluid production, earthwork drilling, sealing/packing, etc., and can solve the problems of low production efficiency, inability to quantitatively evaluate total oil production and oil production, and many production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific embodiments.

[0055] According to an embodiment of the method for interfracture interval water injection and oil recovery in a multi-stage fractured horizontal well according to the present invention, it includes the following steps in a sequence:

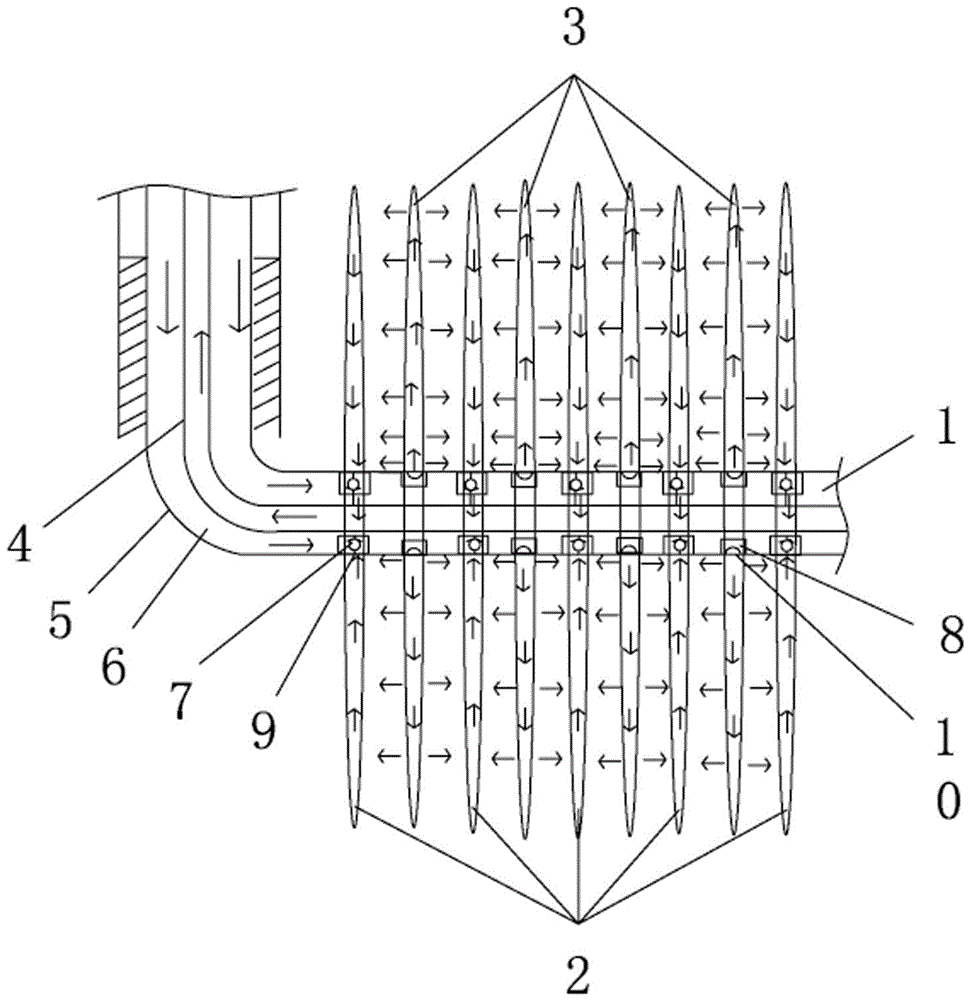

[0056] Step 1: Perform staged fracturing on the wellbore of the horizontal well to form multiple fracturing fractures perpendicular to the wellbore of the horizontal well;

[0057] Step 2: Set up a check valve at each odd-numbered crack position, and install an injection valve at each even-numbered crack position;

[0058] Step 3: In the early stage of production, use natural energy to extract for a period of time until the bottom hole pressure drops to the bubble point pressure;

[0059] Step 4: Use the fracture interval to inject water for exploitation, automatically close the one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com