Quick joint with pressure limit function

A fast and functional technology, applied in mechanical equipment, couplings, etc., can solve the problems of motor casing breakage, motor shaft seal damage, scrapping, etc., and achieve the effect of simplifying the oil circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

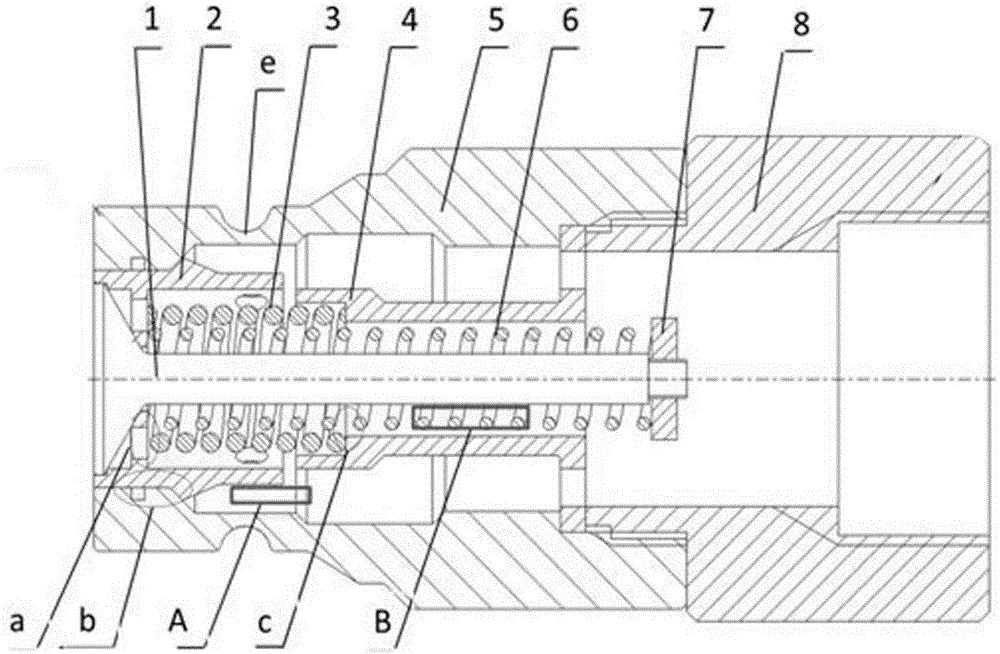

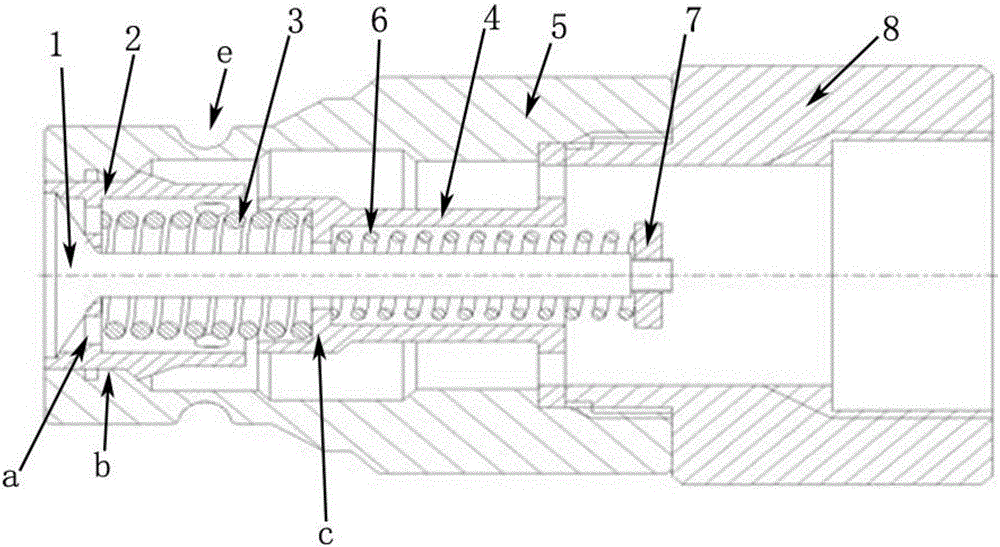

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0019] In the prior art, the use of the motor is taken as an example. At present, the pressure relief method of the motor casing is to connect a check valve or overflow valve with a certain back pressure in parallel on the quick-plug oil circuit. After the quick-plug is disconnected, the motor casing If the internal hydraulic oil pressure rises, the hydraulic oil can leak directly into the atmosphere through the parallel valve to form a pressure relief. Although the above scheme plays the same role, if the selected one-way valve or overflow valve is damaged, the hydraulic oil in the motor casing will not return to the oil tank through the pipeline during normal operation, but will pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com