Heat accumulating type organic waste gas incinerator and running method thereof

A technology of organic waste gas and operation method, which is applied in the field of environmental protection and air pollution control, can solve the problems of low removal rate, sudden drop in the flow rate of the treatment system, damage removal rate, etc., and achieve a simple system, ensure continuity, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

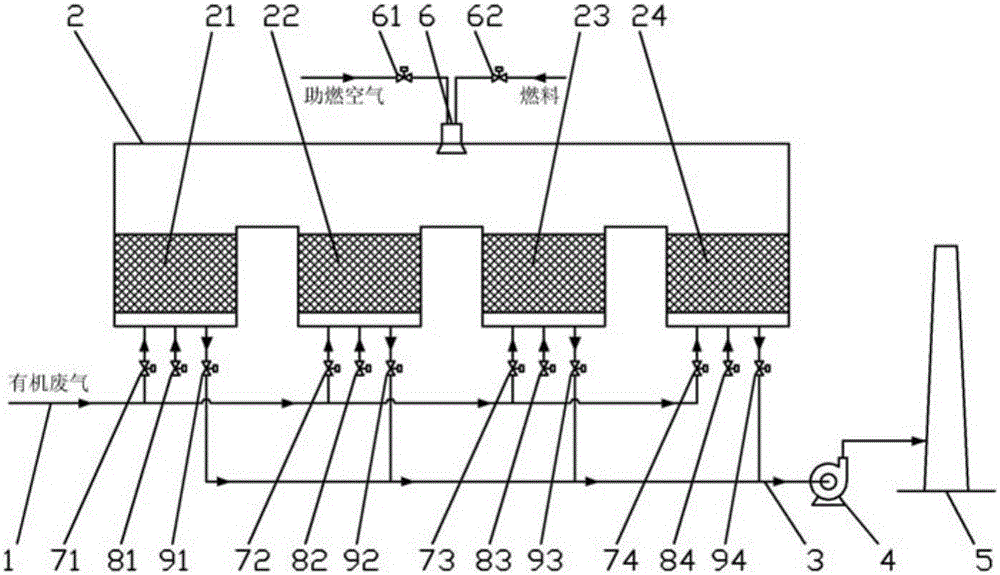

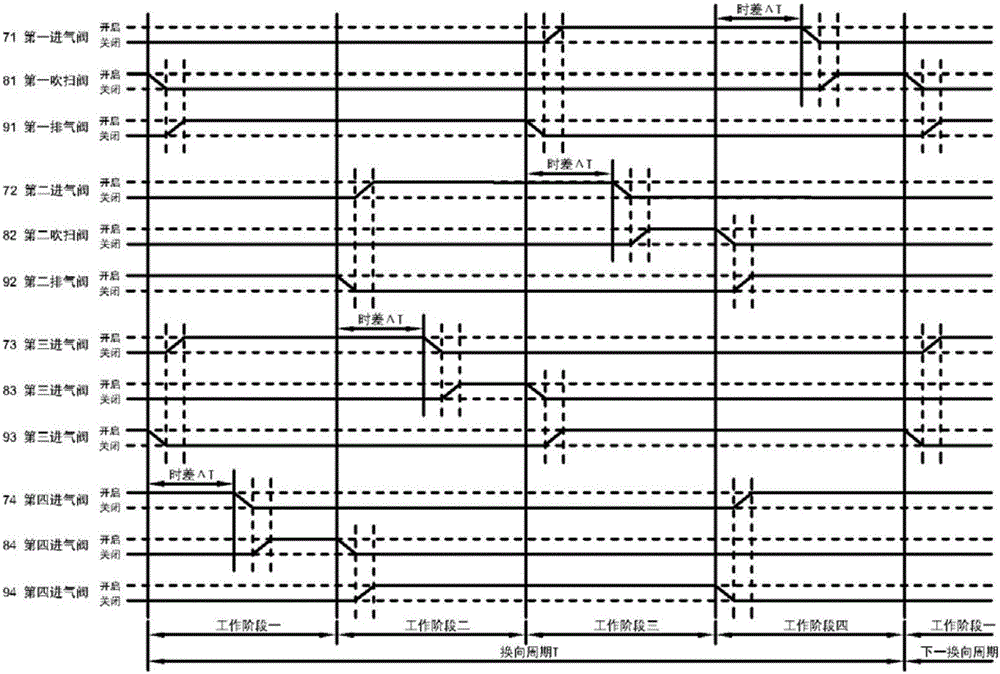

[0023] figure 1 As an embodiment of the present invention, a regenerative organic waste gas incinerator includes: organic waste gas main pipe 1, intake control valve group, incinerator body 2, regenerator, purge control valve group, exhaust control Valve group, flue gas main pipe 3, induced draft fan 4, chimney 5, starting burner 6. A plurality of parallel regenerators are arranged in the incinerator body, the organic waste gas main pipe 1 is connected in parallel with the exhaust gas inlet of each regenerator through the intake control valve group, and the flue gas outlet of each regenerator is connected with the exhaust gas control valve group. The flue gas main pipes 3 are connected in parallel, and the air inlet of each regenerator communicates with the atmospheric environment through the purge control valve group. The flue gas main pipe 3 is connected to the air inlet of the induced draft fan 4 , and the air outlet of the induced draft fan 4 is connected to the chimney 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com