A water collection and return combined well structure with the filter tube moving down

A filter tube and well structure technology, which is applied in the field of water source heat pumps, can solve the problems of reducing the filtering effect, soil loss in the filter material layer, increasing construction and operating costs, etc., and achieve the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

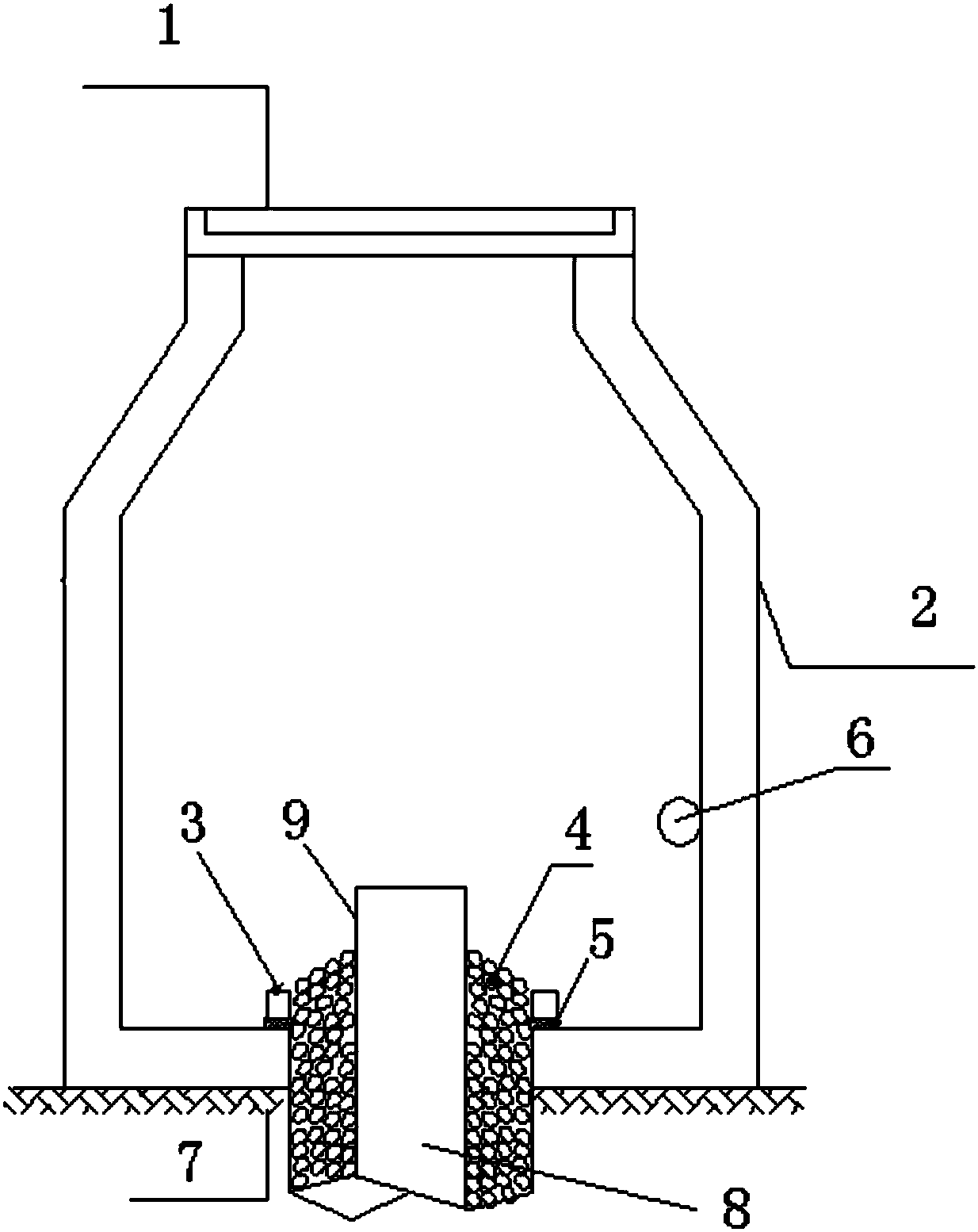

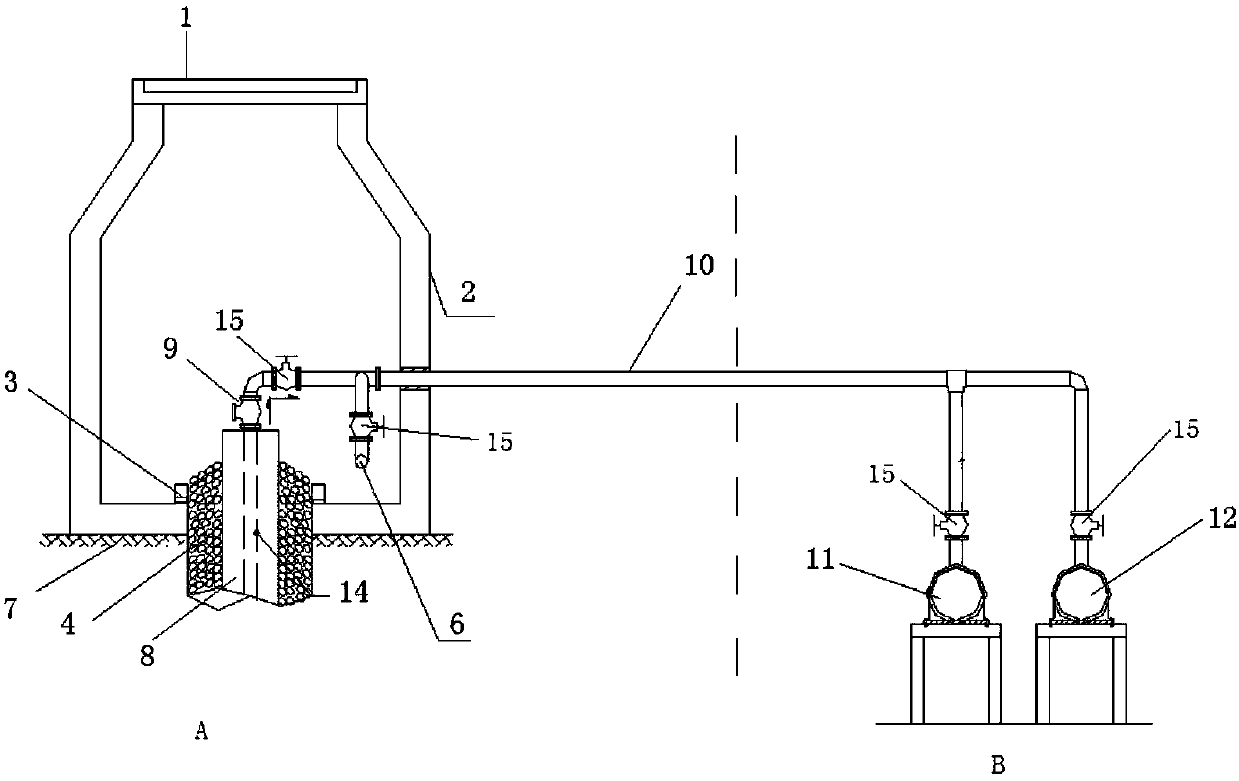

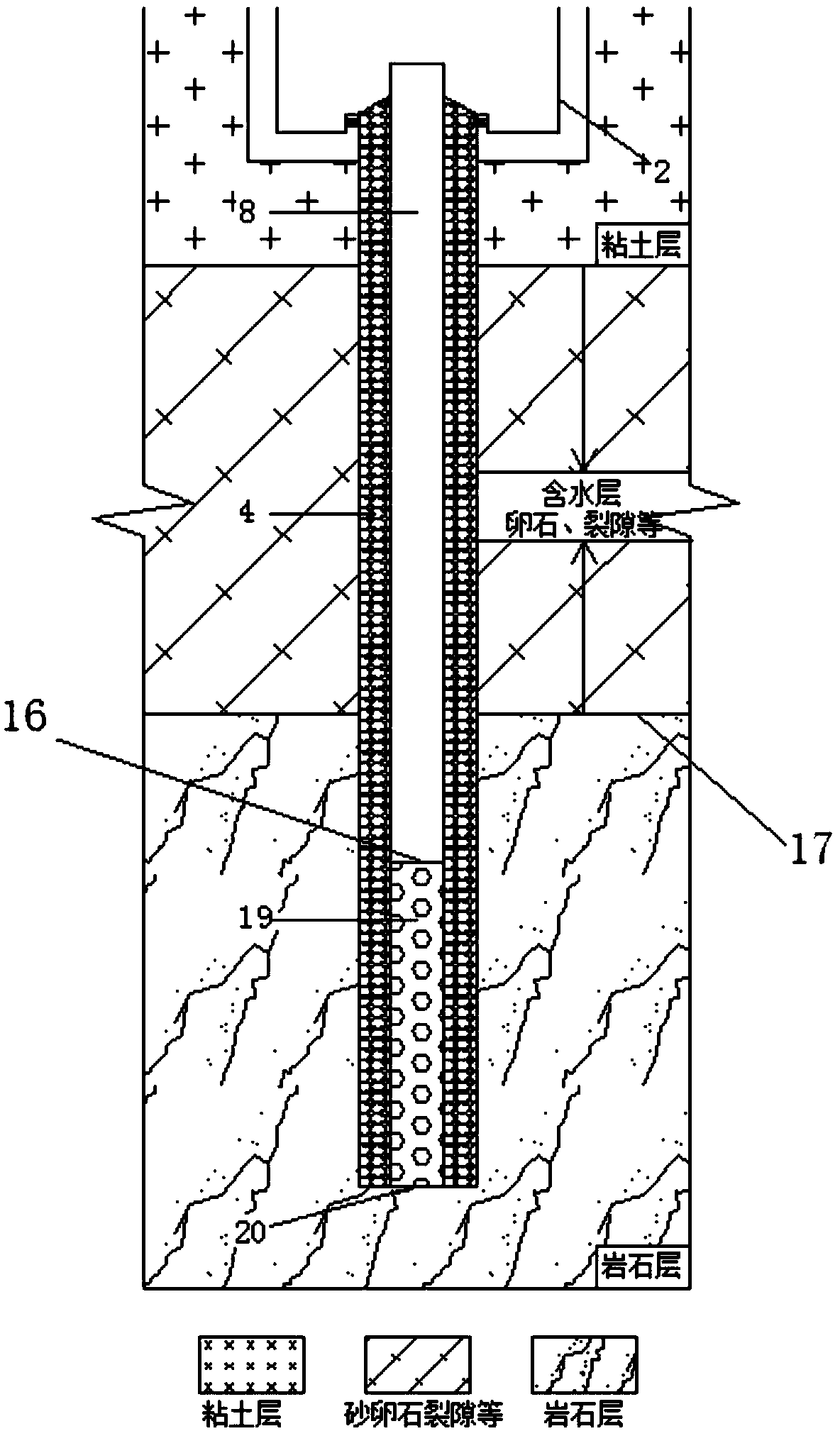

[0016] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 4 As shown, the present invention includes an inspection well 2, and the inspection well 2 is arranged on the original soil layer 7; The outer side is the filter material layer 4; the water-lifting pipe 14 is inserted into the well pipe and connected with the submersible pump; the water-lifting pipe 14 is connected with the main pipeline 10 through the one-way valve 9 and the valve 15; the return pipe 6 is arranged at the lower end of the detection well, and the return pipe 6 Connect with the main pipeline 10 through the valve 15; the main pipeline 10 is respectively connected with the water collector 11 and the water distributor 12 through the valve 15; The top 16 is lower than the top 17 of the rock formation.

[0017] The valve 15 between the water lifting pipe and the main pipeline, the valve 15 between the water return pipe and the main pipeline, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com