Strontium-containing mesoporous bioglass-magnesium composite and preparation method therefor and application of composite

A technology of biological glass and composite materials, applied in tissue regeneration, medical science, prosthesis, etc., to achieve the effect of uniform calcium and phosphorus layer, high strontium loading and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

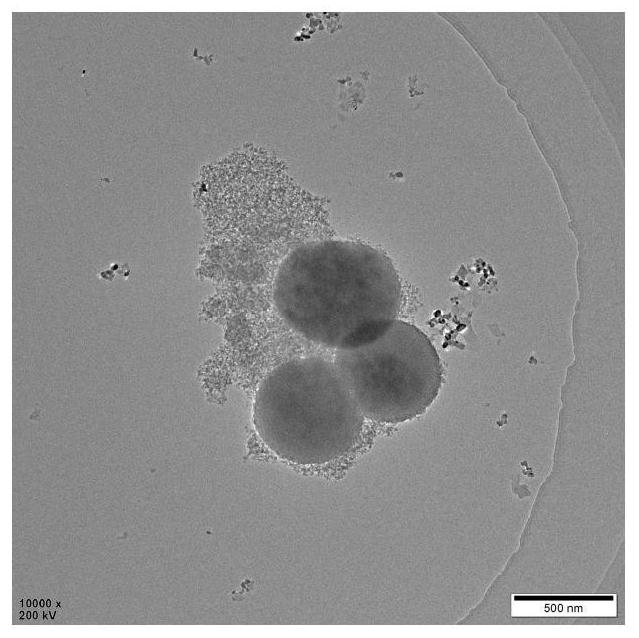

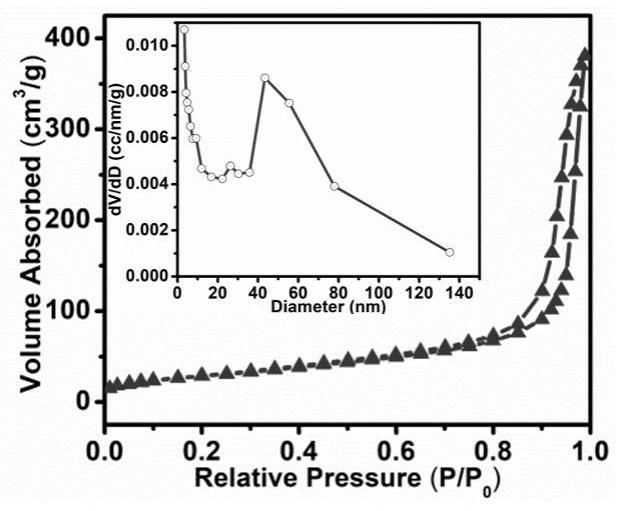

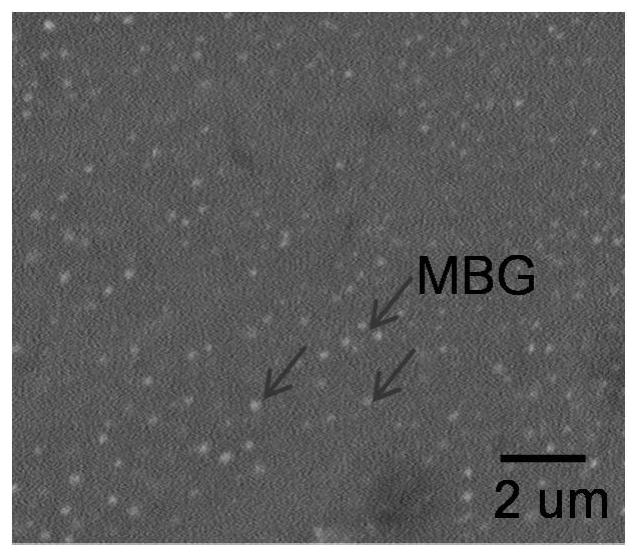

[0059] Step 1: the preparation method of mesoporous bioglass microspheres containing strontium,

[0060] (1) Dissolve 4 g of dodecylamine (DDA) in 125 mL of ethanol aqueous solution, wherein, alcohol: water = 4: 1, stir magnetically for 30 minutes, and the temperature is 40° C.

[0061] (2) Add 16 mL of tetraethyl orthosilicate (TEOS), 1.22 mL of triethyl phosphate (TEP), and 3.99 g of calcium nitrate (CN) to the system of step (1) in an orderly manner, each One-step magnetic stirring for 30min.

[0062] (3) 0.84 g of strontium nitrate (Sr) was added to the system of step (2), and magnetically stirred for 3 h until a white precipitate was formed.

[0063] (4) The solution obtained in step (3) was centrifuged, and washed 3 times with deionized water to obtain a white precipitate.

[0064] (5) Place the white precipitate obtained in step (4) in a vacuum drying oven, set the temperature at 60° C., and dry for 24 hours to obtain a white powder.

[0065] (6) Place the white powd...

Embodiment 2

[0072] Other conditions are all identical with embodiment 1, just distribute according to design group, design biological glass / magnesium powder mass ratio is 8%, weigh the mesoporous biological glass powder 0.8g that contains strontium, 9.2g magnesium-zinc alloy powder (average particle diameter 50μm). Ball milling was performed in an argon protective gas atmosphere to obtain a mixed powder, the rotational speed of the ball mill was 300 rad / min, and the ball milling time was 2 h. Using the above mixed powder as raw material, the magnesium metal of mesoporous bioglass containing strontium was prepared by laser selective melting process. During the preparation process, the laser power was 90W, the scanning speed was 120mm / s, and the laser spot was 100μm

[0073] The test found that compared with magnesium metal with a mass ratio of bioglass / magnesium powder of 5%, the density of magnesium metal showed a downward trend, which accelerated corrosion. The degradation rate of the al...

Embodiment 3

[0075] Other conditions are all identical with embodiment 1, just distribute according to design group, design biological glass / magnesium powder mass ratio is 4%, weigh the mesoporous biological glass powder 0.4g containing strontium, 9.6g magnesium-zinc alloy powder (average particle diameter 50μm). Ball milling was performed in an argon protective gas atmosphere to obtain a mixed powder, the rotational speed of the ball mill was 300 rad / min, and the ball milling time was 2 h. Using the above mixed powder as raw material, magnesium metal of mesoporous bioglass containing strontium was prepared by selective laser melting process. During the preparation process, the laser power was 90W, the scanning speed was 120mm / s, and the laser spot was 100μm. According to measurements, in Example 2, the degradation rate of the obtained strontium-containing mesoporous bioglass-magnesium composite material was 0.38 mm / year, and the compressive strength was 150 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com