Measuring system and measuring method for thickness of water film on inner wall of humidity sensor by adopting microwave perturbation method

A technology of humidity sensor and microwave perturbation method, which is applied to the system for measuring the thickness of water film on the inner wall of the vapor humidity sensor. The microwave perturbation method is used to measure the thickness of water film on the inner wall of the humidity sensor, which can solve the problems of complex equipment and high cost of the optical fiber method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

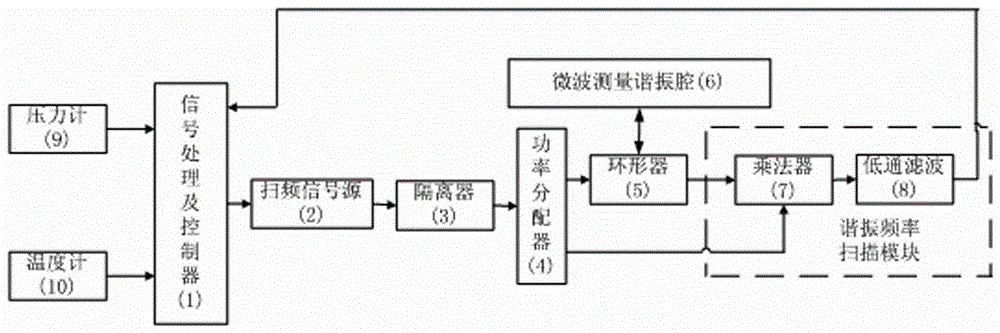

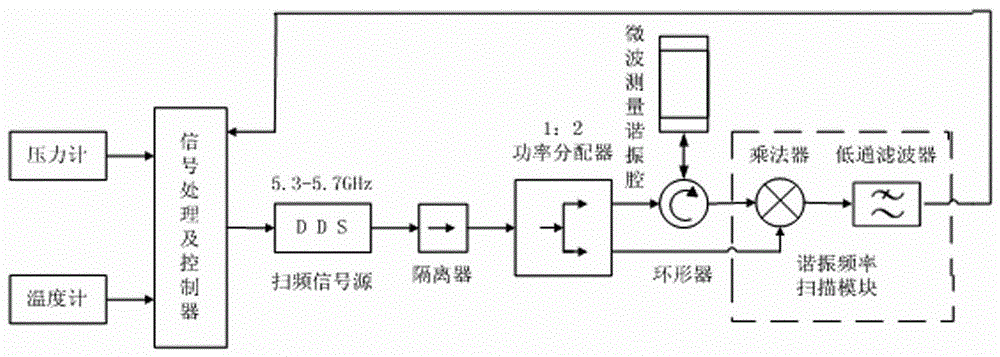

[0038] Such as figure 1 As shown, it is composed of signal processing and controller 1, frequency sweep signal source 2, isolator 3, power divider 4, circulator 5, microwave measurement resonant cavity 6, resonant frequency scanning module, pressure gauge 9 and thermometer 10; Described resonant frequency scanning module is made up of multiplier 7 and low-pass filter 8;

[0039] The output terminals of the pressure gauge 9 and the thermometer 10 are connected to signal processing and the corresponding input terminals of the controller 1, the signal processing and the control output terminals of the controller 1 are connected to the input terminals of the frequency sweep signal source 2, and the frequency sweep signal The source 2 generates a frequency sweep signal under the control of the signal processing and controller 1, and the sweep signal is input to the power divider 4 through the isolator 3, and the signal output by the power divider 4 passes through the circulator 5 a...

Embodiment 2

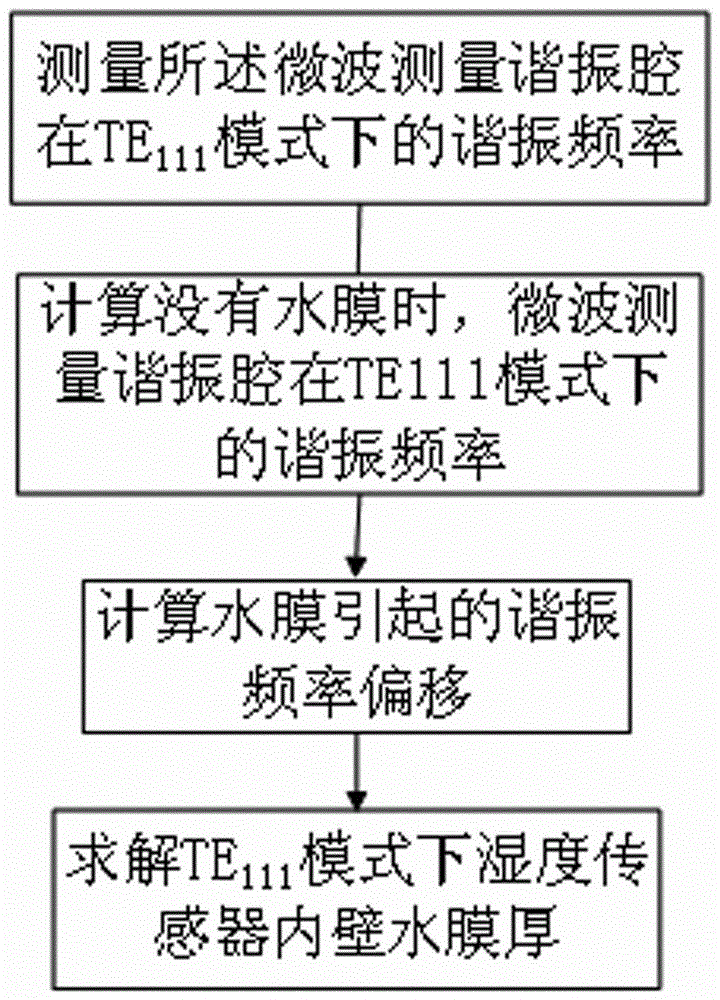

[0047] Such as image 3 Shown, a kind of measuring method for the system described in embodiment 1 is characterized in that: comprise the following steps:

[0048] Step 1: Measure the microwave measurement cavity 6 at the TE 111 The resonant frequency f in the mode 1 ;

[0049] Step 2: Calculate the microwave measurement cavity 6 at TE when there is no water film 111 Resonant frequency in mode:

[0050] f 02 = c 2 π ϵ r m - ( 1.841 a ) 2 + ( π ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com