Intelligent carbon board prepared from fiber reinforced plastics and preparation method of intelligent carbon board

A fiber-reinforced plastic and intelligent technology, which is applied in the direction of measurement, measuring devices, instruments, etc. by measuring the change in optical properties of materials when they are stressed, can solve the problem of difficulty in adapting to extensive construction requirements and inability to ensure the stress state of carbon plates Long-term stable monitoring, sensors and transmission lines are easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] In order to achieve the purpose of the present invention, in some embodiments of the fiber-reinforced plastic smart carbon plate,

[0044] In order to achieve the above object, technical scheme of the present invention is as follows:

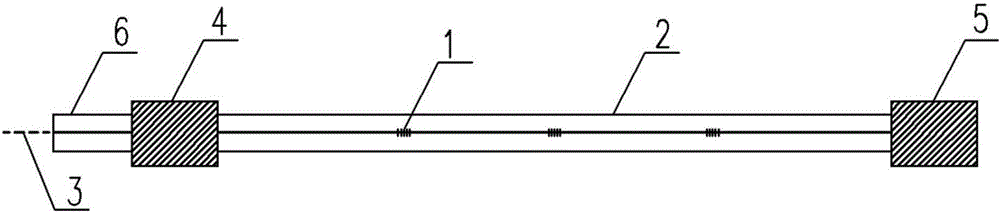

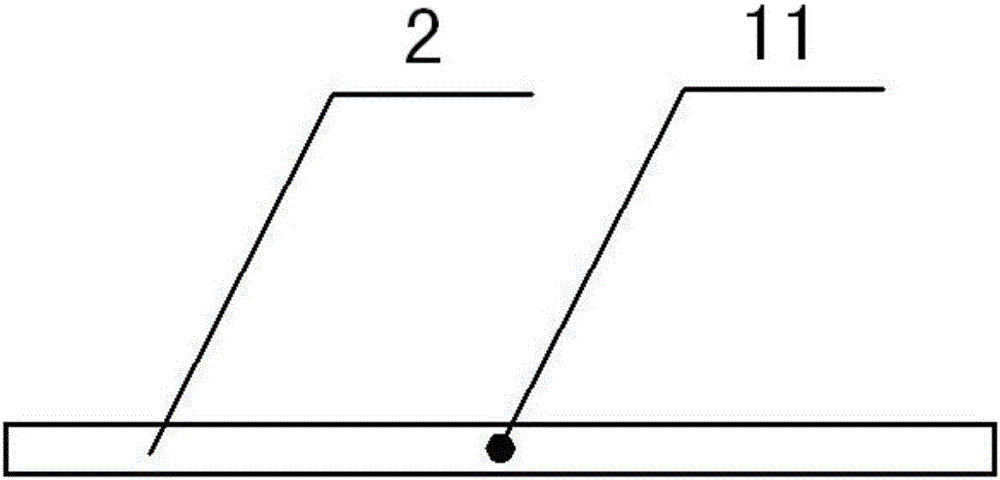

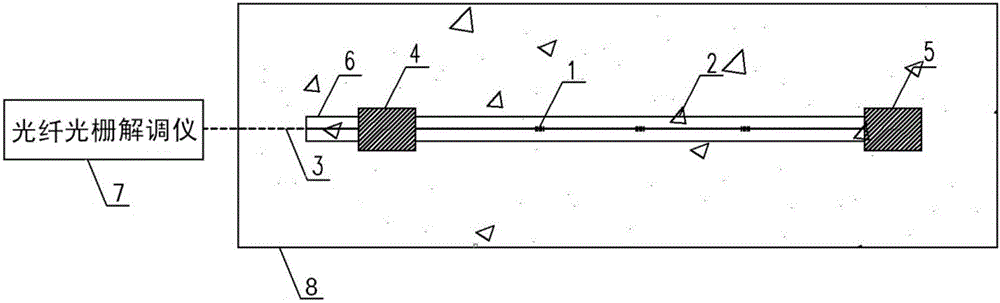

[0045] like Figure 1-3 As shown, a fiber reinforced plastic smart carbon plate includes: a fiber grating sensor 1, a coating part 2 arranged outside the fiber grating sensor 1 and an anchor assembly arranged outside the coating part 2, and the coating part 2 is made of fiber reinforced plastic The fiber grating sensor 1 is connected with the fiber grating demodulator 7 through the test jumper 3 . The outer surface of the cladding part 2 is a smooth plate.

[0046] The fiber grating sensor 1 is a single-mode fiber 11 in which one or more fiber gratings are written.

[0047] The anchor assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com