Method for detecting and reconstructing defect of axially symmetrical bodies on basis of wave number spatial spectra of sound fields

An axisymmetric body and defect detection technology, which is applied in the direction of material analysis, measurement device, and processing of detection response signals using sonic/ultrasonic/infrasonic waves, which can solve the problem of large error in defect reconstruction results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

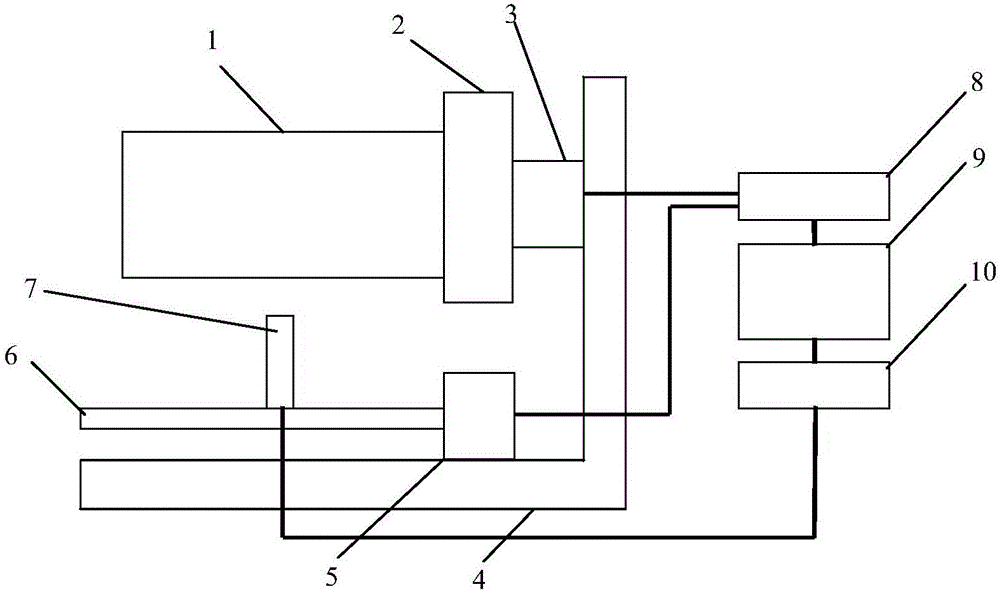

[0023] Such as figure 1 As shown, the axisymmetric body ultrasonic testing system used in this embodiment includes an axisymmetric body rotating chuck 2, an axisymmetric body rotating motor 3, a "┚" type detection table support seat 4, an ultrasonic probe moving motor 5, and an ultrasonic probe Moving guide rail 6, ultrasonic probe 7, motor control card 8, industrial computer 9, ultrasonic transmitting and receiving card 10, and defect detection and processing software, the axisymmetric body rotating motor 3 is set on the vertical gear of the support seat 4 of the "┚" type inspection table In the upper part of the inner side, the axisymmetric body rotating chuck 2 is installed on the rotating shaft of the axisymmetric body rotating motor 3, the axisymmetric body rotating chuck 2 blocks the axisymmetric body 1 to be checked through the bayonet, and the ultrasonic probe moving motor 5 is located at " ┚” type testing platform support base 4, the ultrasonic probe moving guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com