A Reconstruction Method for Ellipse-like Defects in Axisymmetric Workpieces

An axisymmetric, ellipse-like technology, which is applied to instruments, measuring devices, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as large reconstruction errors, and achieve the effects of simple methods, easy implementation, and improved computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

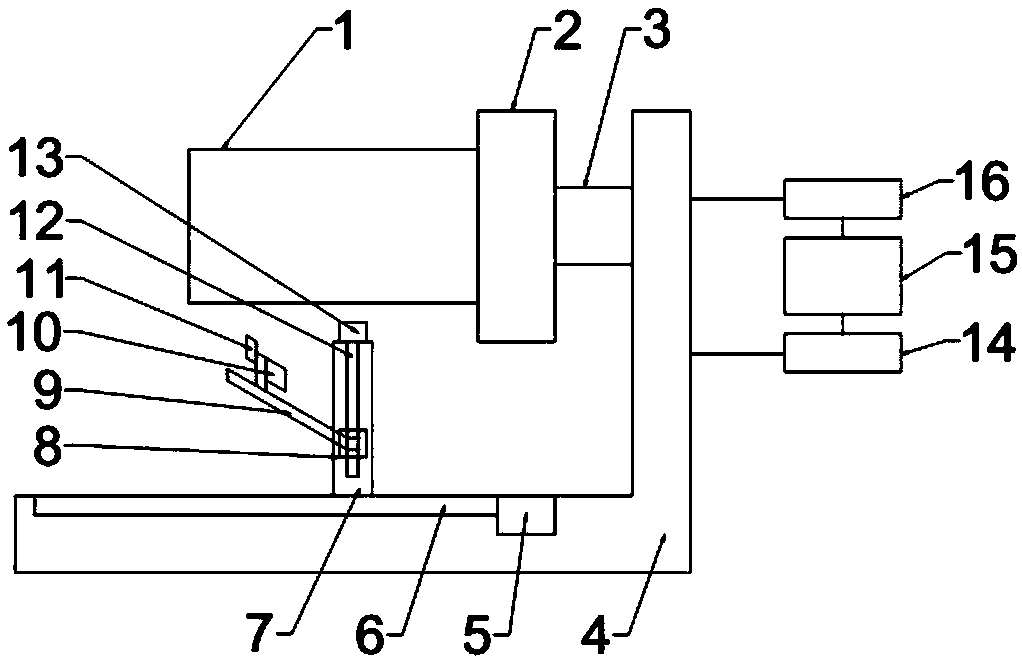

[0049] like figure 1 As shown in the figure, the ultrasonic inspection system for axisymmetric workpieces used in this embodiment includes an axisymmetric workpiece rotating chuck 2, an axisymmetric workpiece rotating motor 3, a "┚" type inspection table support 4, an ultrasonic probe forward and backward moving motor 5, an ultrasonic Probe back and forth moving guide 6, ultrasonic probe support frame 7, ultrasonic probe inside and outside moving motor 8, ultrasonic probe inside and outside moving guide 9, ultrasonic probe moving up and down motor 13, ultrasonic probe moving up and down guide 12, ultrasonic probe rotating motor 10, ultrasonic probe 11. Ultrasonic transmitting and receiving card 14, industrial computer 15, motor control card 16 and defect detection and processing software, the axisymmetric workpiece rotating motor 3 is set on the upper part of the inner side of the vertical file of the "┚" type test stand support seat 4, and the axis is symmetrical The workpie...

Embodiment 2

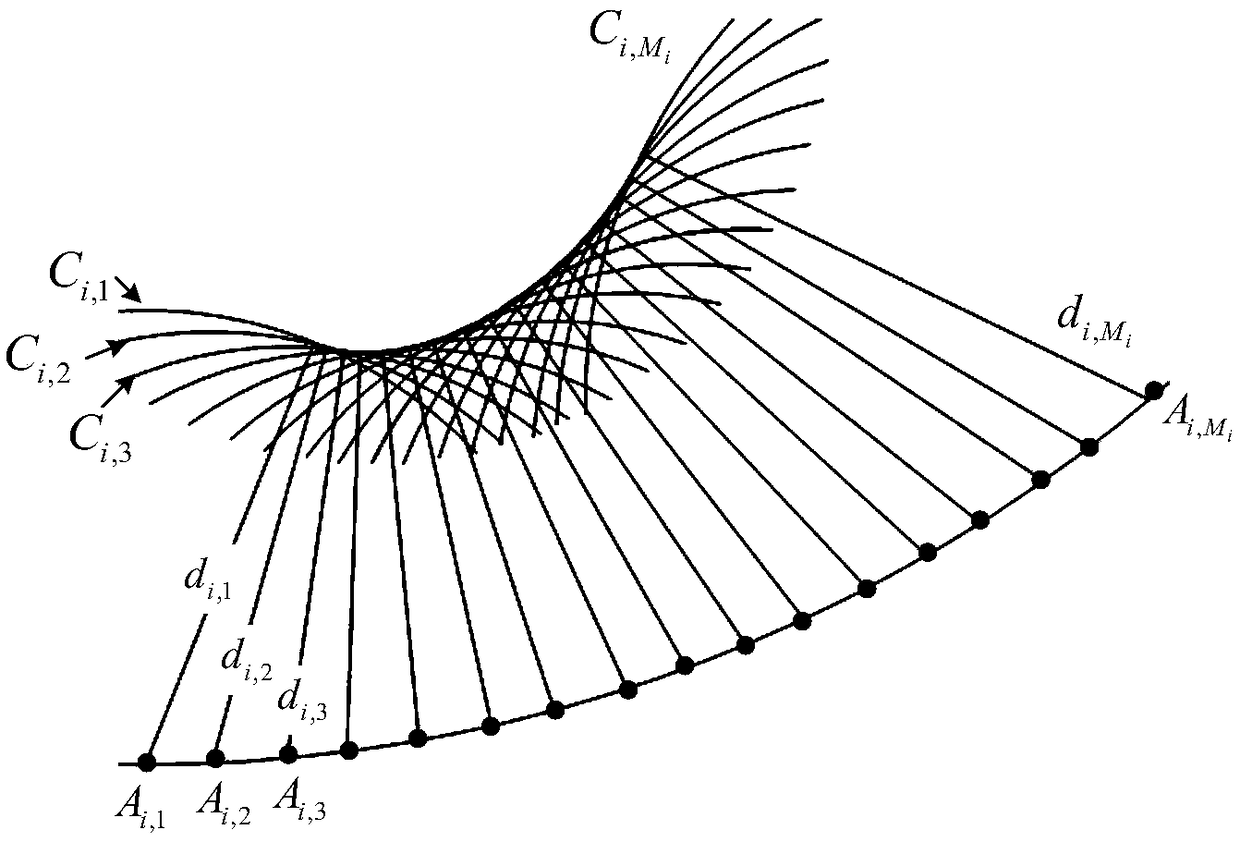

[0059] In this embodiment, the data collection is the same as that of Embodiment 1. The ultrasonic probe adopts a straight probe with a center frequency of 5MHz, and the circumferential step angle is Δθ=1°, that is, 360 ultrasonic signals are collected at equal intervals on the surface of the workpiece. The sampling interval of the ultrasonic signal is Δt=0.02 μs. The axisymmetric workpiece is an aluminum alloy bullet blank with a total length of 80mm. The external dimensions are divided into three sections: a thin end with a diameter of 58mm, a thick end with a diameter of 70mm, and a transition cone. The internal dimensions are divided into three sections: cylindrical hollow body, Conical hollow body and cylindrical solid body, with three hole-like defects with a diameter of about 1.5mm inside the butt end cylindrical hollow body ( Figure 16 , 19 , No. Ⅰ, Ⅱ, Ⅲ in 20), one of which is a drill bit fracture inclusion), and a hole-like defect with a diameter of about 1.5mm ins...

Embodiment 3

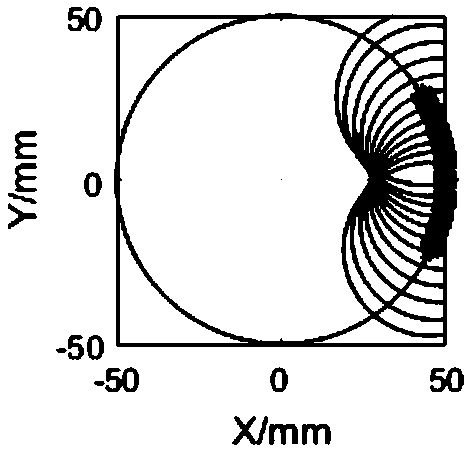

[0062] Since the actual defect size cannot be accurately estimated, the detection signal may be affected by other factors. In order to illustrate the universality and accuracy of the reconstruction method of the present invention, the present invention adopts COMSOL simulation software to simulate the transmission and acquisition of ultrasound according to the actual principle of ultrasonic transmission and reception, and obtains a simulated echo signal that simulates step 1) in Example 1. The process carries out data simulation, and the time step of the simulated echo signal is Δt=0.1 μs. In this embodiment, reconstruction is performed separately for two axisymmetric workpieces. The axisymmetric workpiece is a solid aluminum cylinder with a diameter of 100mm. Taking the center as the origin, there is a hole with a diameter of 10mm at (0, -25), and a long axis of 12mm and a short axis at (25,0). The second is a hollow aluminum cylinder with an outer diameter of 100mm and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com