Fin separating-sheet type helical radiant tube

A spacer type and radiant tube technology, which is applied in the field of electrothermal radiant tubes, can solve the problems of electrothermal radiant tube damage, breakdown of radiant tube sleeves, easy cracking and fragility, etc., and achieve the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

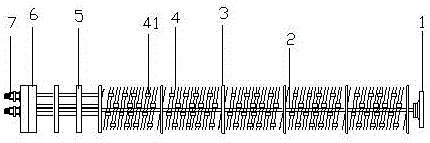

[0010] Such as figure 1 As shown, a finned spacer type spiral radiant tube is composed of a corundum base 1, a central tie rod 2, a heat-resistant steel support piece 3, a flat belt high-temperature electric heating element 4, a corundum spacer 5, and a corundum ceramic circle. plate 6 and conductive bolts 7, one end of the center tie rod 2 is vertically installed on the corundum base 1, the heat-resistant steel support piece 3 is vertically installed on the center tie rod 2, and the heat-resistant steel support piece 3 is provided with several , between the heat-resistant steel support piece 3 and the heat-resistant steel support piece 3, several flat belt type high-temperature electric heating elements 4 are arranged. A corundum ceramic disc 6 is installed on one side of the spacer 5 , and a conductive bolt 7 is installed on one side of the corundum ceramic disc 6 .

[0011] Specific implementation: several insulating spacers 41 are arranged on the flat strip type high-temp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap