Rolling tool

一种工具、滚压的技术,应用在制造工具、金属加工设备、为磨削工件旋转面设计的机床等方向,能够解决抛光辊引导件损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

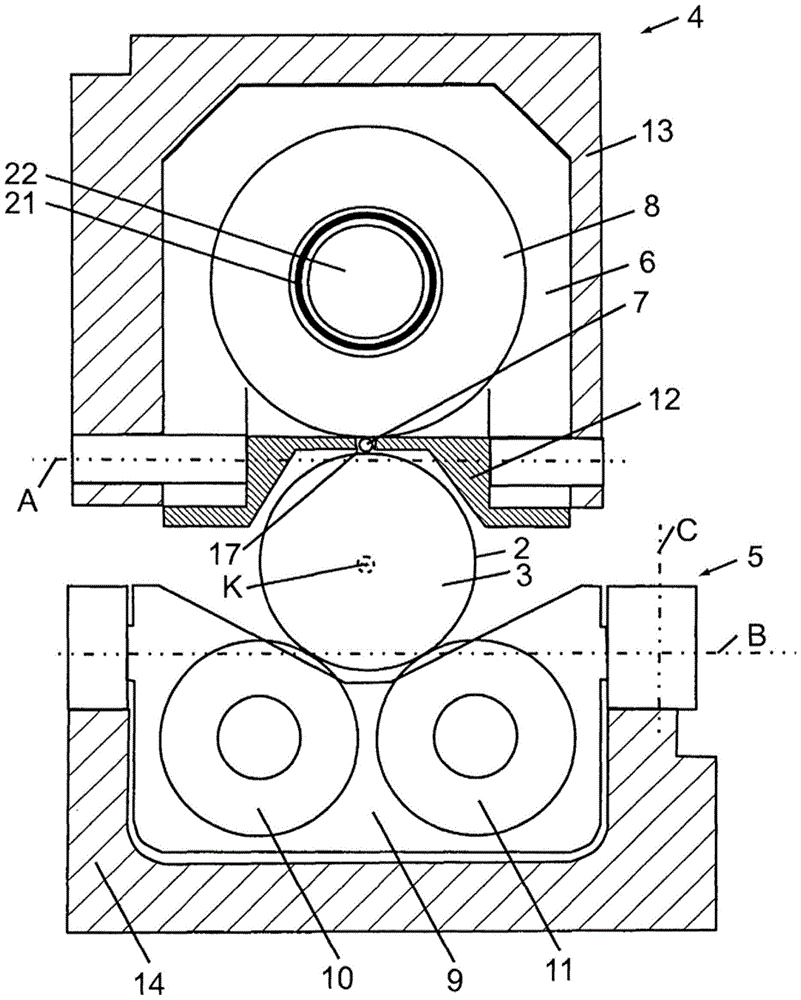

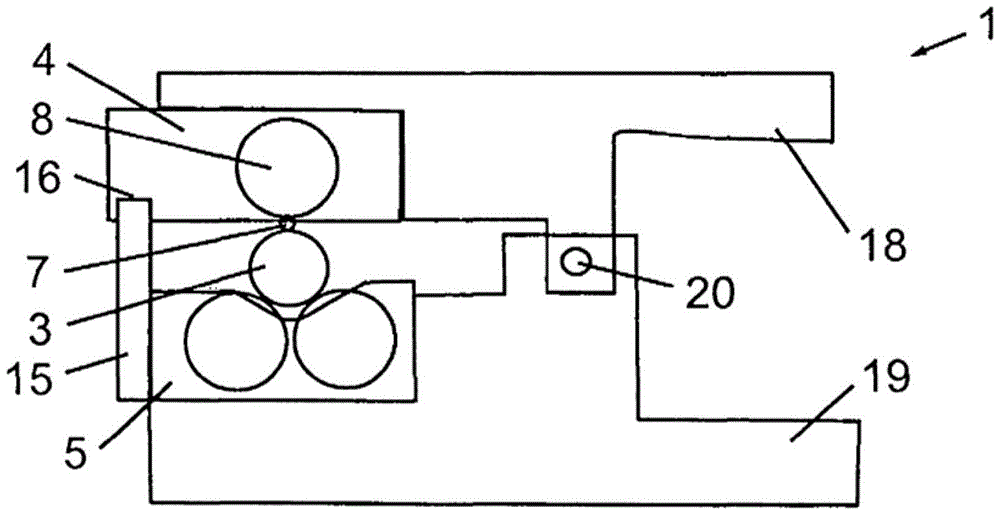

[0031] attached figure 1 The polishing head 4 and the backup roller head 5 on the crankshaft 3 are shown in a schematic cross-section perpendicular to the crankshaft axis K of the crankshaft 3 . The illustrated bearing surface 2 of the crankshaft 3 is the main bearing seat of the crankshaft 3 . The connecting rod bearing and the bearing seat of crankshaft 3 and the remaining bearings can also be processed by polishing head 4 . The polishing head 4 and the backup roller head 5 are narrowly shaped perpendicular to the plane shown, so that there is a distance from the two crank arms connected to the bearing surface 2 in each case. The backup roll head 5 supports the crankshaft 3 against the rolling force exerted on the crankshaft 3 by the polishing head 4 via the polishing roll 7 .

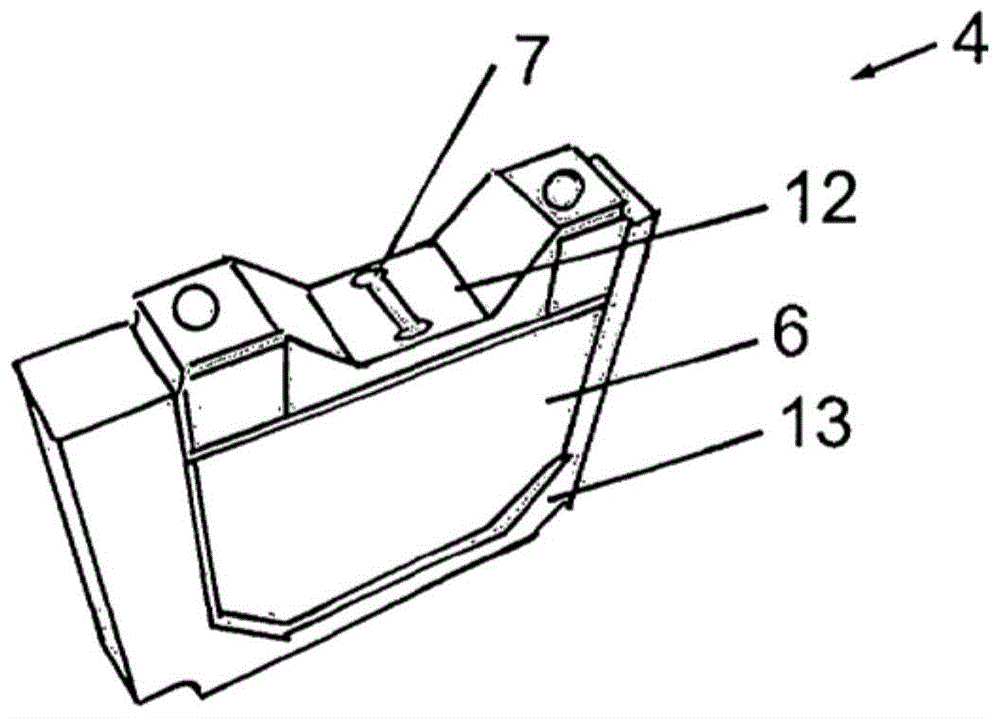

[0032] The polishing head 4 has a polishing head housing 6 which is rotatably mounted about a first rotational axis A in the rolling tool 1 according to the invention in a polishing head frame 13 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com