Color or multi-material three-dimensional (3d) printing

A 3D printer and multi-material technology, applied in 3D object support structures, mixers, additive processing, etc., can solve problems such as insufficient mixing, inability to provide color, complexity, etc., to achieve cost reduction, high-quality color performance, and increase The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

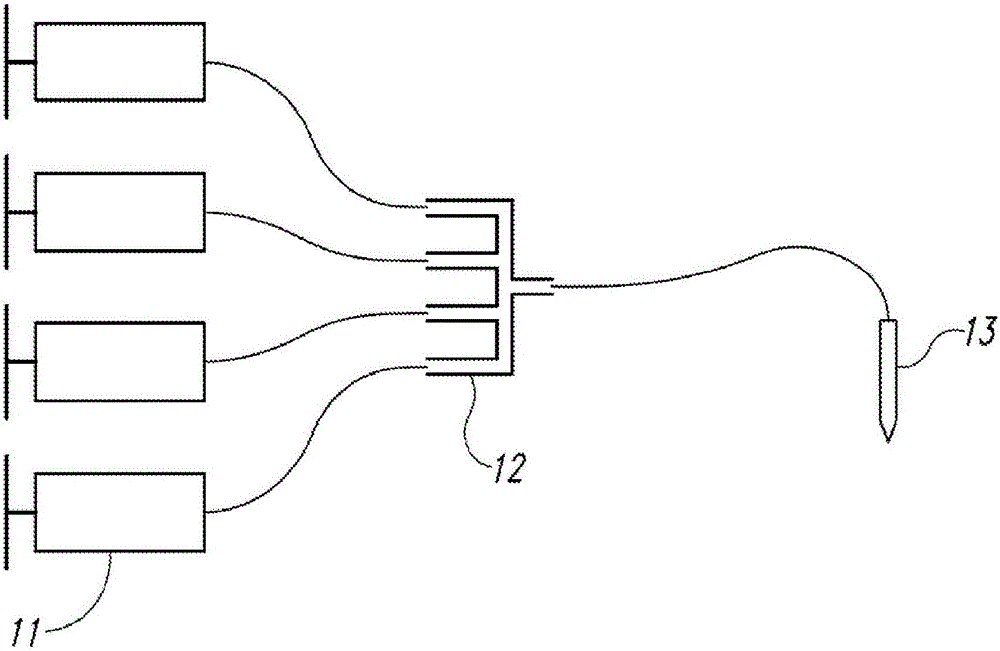

[0028] The following description is a preferred embodiment providing a color 3D printing device using a curable substance as a building material. Such as figure 1 As shown, the color 3D printing system includes a plurality of magazines 11 for building materials, a mixer 12 and a single nozzle 13 with a single thermal extruder. The curable building material contained in the magazine 11 is sent to the spray head 13, and is fully mixed in the process, and finally extruded from the tip of the spray head, and the extruded building material droplets are then solidified.

[0029] Each magazine 11 contains building materials, and a plurality of magazines are used to accommodate building material liquids with different properties (such as color, hardness or specific gravity). In one embodiment, the building material is contained in a syringe to facilitate delivery. The holding container can also be a thin tube, a bottle or any other liquid container that can facilitate the delivery o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com