Detachable wiper device for manual window cleaning

A technology of glass scraping and manual cleaning, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., to achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, identical and identically acting components are provided with the same reference symbols unless otherwise stated.

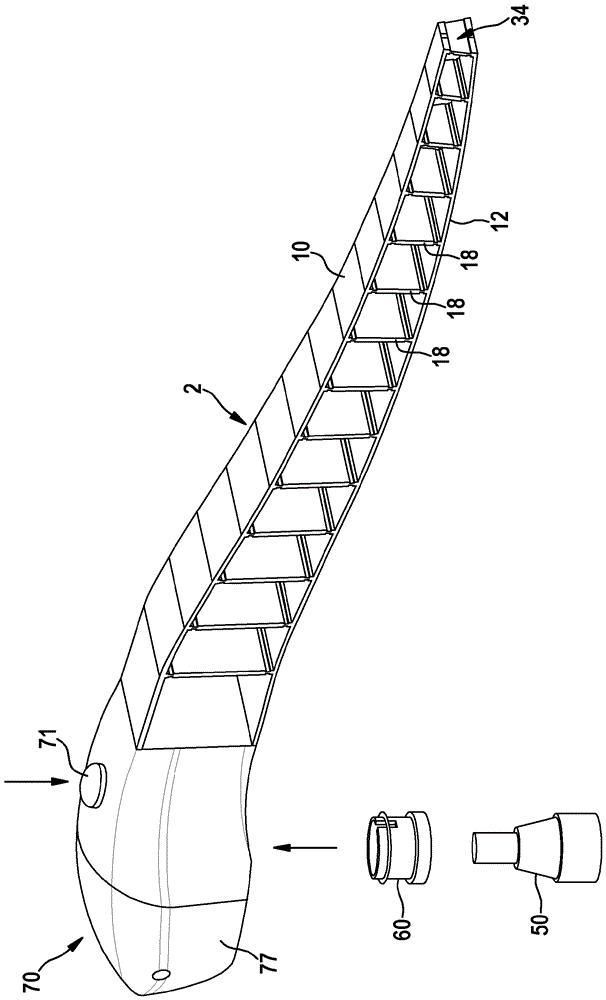

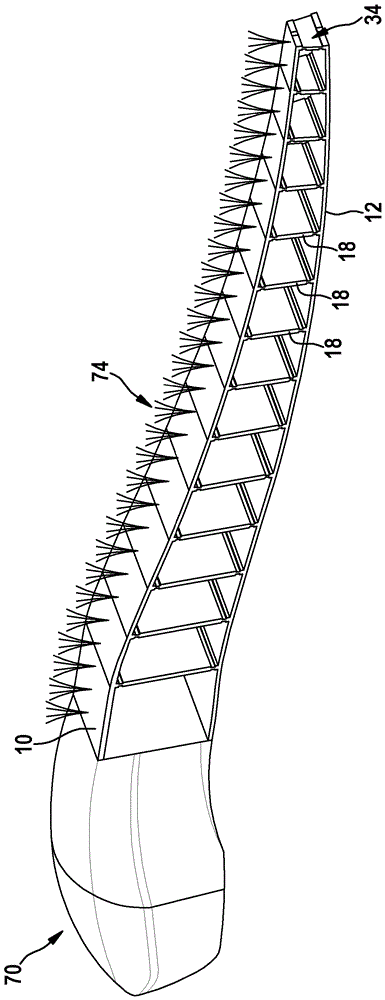

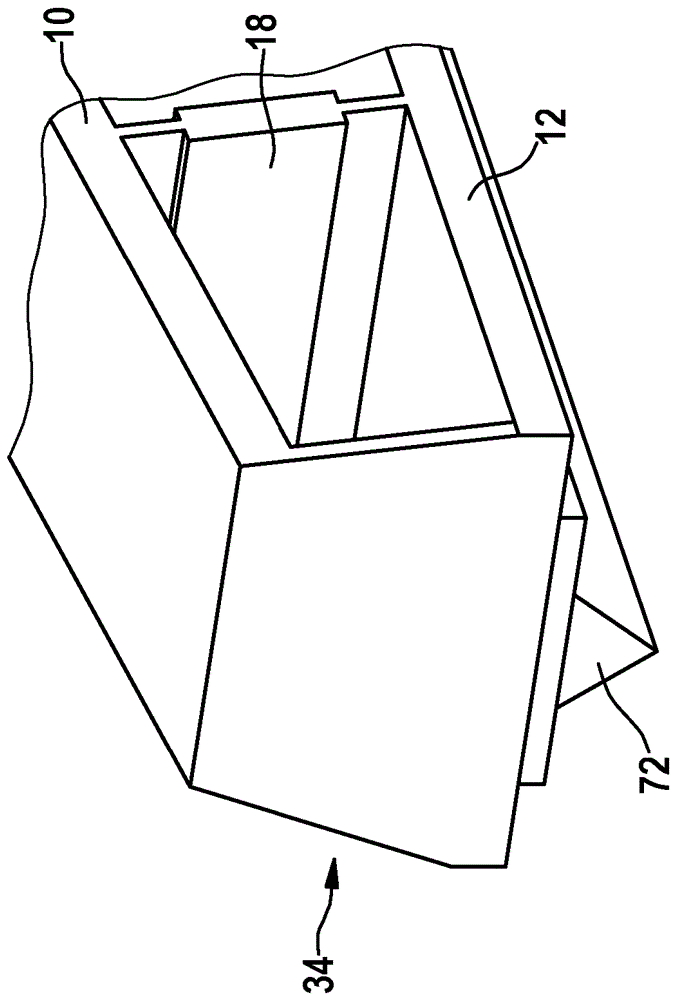

[0041] figure 1 A wiper blade 2 of a windshield wiper device according to an embodiment of the invention is shown. In particular, the windshield wiper device is a fin-ray wiper. The wiper blade comprises an elongated upper part 10 and an elongated lower part 12 . The upper part 10 and the lower part 12 are designed to be at least partially bendable. The upper part 10 and the lower part 12 are connected to each other by connecting elements 18 . The connecting elements 18 are spaced apart from one another along the longitudinal extension of the wiper blade 2 and are designed in such a way that the upper part 10 and the lower part 12 can be moved relative to each other mainly along the longitudinal extension. Furthermore, the wiper blade 2 is wedge-shaped, wherein the upper part 10 and the lower part 12 are connected to one another at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com