Method for operating a piezo servo injector

A technology of injectors and piezoelectric actuators, applied to fuel injection valves driven by fluid pressure, fuel injection devices, fuel injection control, etc., can solve the problems of accuracy and robustness, slow adaptation methods, etc., to achieve The effect of high accuracy and high level of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

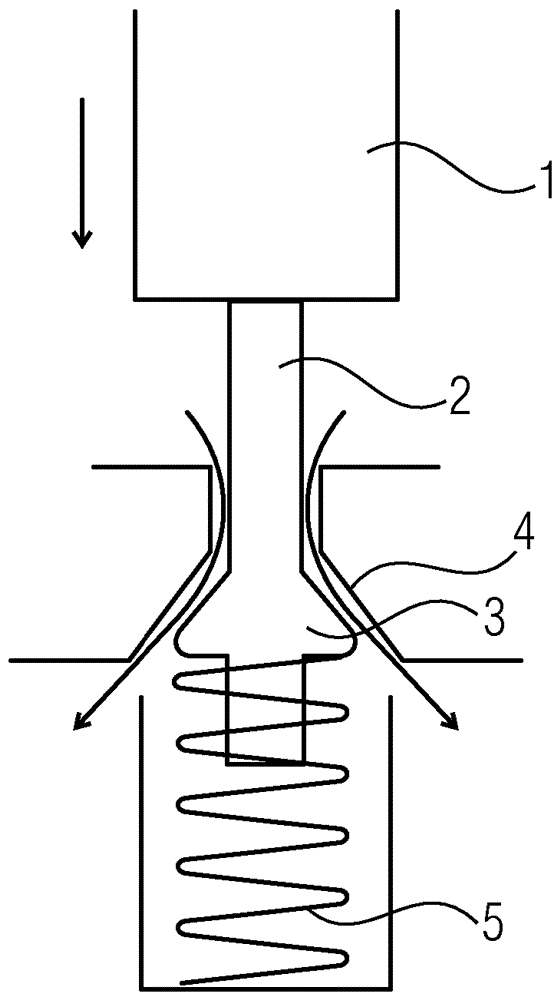

[0020] figure 1 A part of an injector of an internal combustion engine is shown, the nozzle needle (not shown) of which is actuated by a piezoelectric actuator 1 by means of a servo valve 2 . The servo valve 2 has a mushroom-shaped valve body 3 interacting with a valve seat 4 . The spring 5 presses the valve body 3 against the valve seat 4 . When voltage is applied to the piezoelectric actuator 1, said piezoelectric actuator expands downwards in the figure and in this way the valve body 3 of the servo valve 2 is downwards in the figure due to the force of the spring 5 The movement is such that a flow channel is thus opened between the valve seat 4 and the valve body 3 , through which the fuel flows and thus enables a movement of the nozzle needle (not shown) for starting the injection process to be carried out.

[0021] When the voltage applied to the piezoelectric actuator 1 is turned off, the piezoelectric actuator contracts, causing the valve body 3 to move the spring 5 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com