A juicer with built-in heating function

A juicer and functional technology, applied in the field of juicer with heating function, can solve the problems of increased pulping time and poor pulping efficiency, and achieve the effects of overcoming space occupation, reducing costs, and promoting the speed of popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

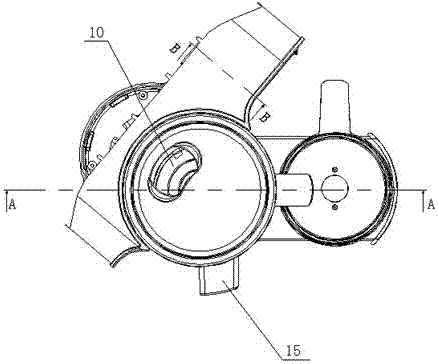

Image

Examples

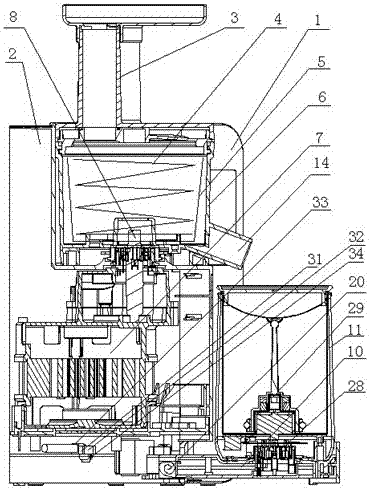

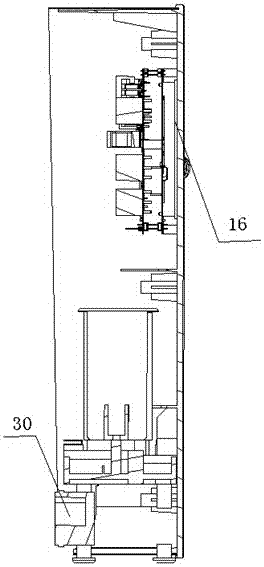

Embodiment 1

[0023] Embodiment 1: This embodiment takes squeezed fruit juice as an example, first connect an external power supply through the power supply interface 30, and press the switch key on the display screen 16 after it is connected; then clean the fruit (such as apples, pears, oranges, etc.) Put the cut pieces into the raw material inlet 13; then press the juice key on the display screen 16, and the motor 7 drives the motor shaft 8 to rotate after being energized. With the rotation of the motor shaft 8, the squeeze head 4 also rotates. At this time The fruit entering the squeeze cup body 6 is squeezed into juice by the squeeze head 4, and the squeezed fruit pomace is discharged from the slag outlet 15, and the juice flows out from the juice outlet 14 after being filtered by the filter 5, and the juice that flows out at this time The temperature of the juicer is preset by the electric control system of the juicer. Usually the temperature of the juice is about 33 degrees. If the ta...

Embodiment 2

[0024] Embodiment 2: This embodiment takes pressing soybean milk as an example, first connect an external power supply through the power inlet port 30, and press the on-off key on the display screen 16 after it is connected; then put the cleaned soybeans from the raw material inlet 13; then press The soya-bean milk key on the lower display screen 16, now motor 7 drives motor shaft 8 to rotate after electrification, along with the rotation of motor shaft 8, squeeze head 4 also rotates thereupon, if the soybeans to be squeezed are soaked in advance, enter at this time The soybeans in the squeeze cup body 6 are squeezed into soy milk by the squeeze head 4. If the soybeans have not been soaked in advance, the soybeans cannot be easily squeezed out of the soybean milk. At this time, you can press the forward rotation key on the display screen 16 or Reverse the key to repeatedly squeeze the soybeans; the squeezed soybean dregs are discharged from the dregs outlet 15, and the soybean ...

Embodiment 3

[0025]Embodiment 3: This embodiment takes directly boiling water as an example, first connect an external power supply through the power supply interface 30, press the switch key on the display screen 16 after switching on, and then pour the water to be boiled into the cup of the heating stirring cup 11 Inside the body, press the end face of the moving main body 18, under the action of the power coil spring 20, the moving locking buckle 21 is separated from the moving locking buckle 22, the moving main body 18 pops up from the chassis, and then the heating and stirring cup 11 is placed on the moving On the main body 18, the coupler upper assembly 28 at the bottom of the heating and stirring cup 11 is connected to the coupler lower assembly 25 on the moving main body 18. The heating and stirring cup 11 starts to work, heats and stirs the water, and can pass through the display screen 16 during heating. The heating key is used to select suitable heating time and heating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com