A kind of preparation method of synthetic gas methanation catalyst

A catalyst and gas methane technology, which is applied in the field of preparation of a supported nickel-based catalyst for the methanation of synthesis gas, can solve the problems of low metal utilization rate of carrier pores, increased catalyst preparation cost, and little contribution to the target reaction of the catalyst, and achieves improved conversion. rate and product selectivity, avoid further conversion, and accelerate the effect of adsorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

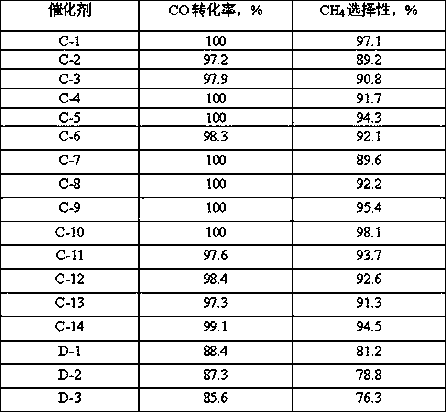

Examples

Embodiment 1

[0026] Mix an appropriate amount of n-octane, n-hexanol and Tween 80 to make a stable microemulsion. Add an aqueous solution containing an appropriate amount of nickel nitrate and ammonium molybdate to the microemulsion, stir well at 40°C, and then add an appropriate amount of 60% Hydrazine hydrate solution, after stirring for 5 hours, add an appropriate amount of alumina (the pore volume is 0.71ml / g, the specific surface area is 236m 2 / g) Carrier, after stirring for 2h at 80℃, filter, the solid precipitate obtained is washed 4 times with ethanol, then dried at 110℃ for 5h, calcined at 450℃ for 6h, to prepare catalyst precursor A, Ni is calculated as element The weight of the carrier is 3%, and Mo accounts for 2% of the weight of the carrier based on elements; n-octane: n-hexanol: Tween 80: active component nickel: first auxiliary molybdenum = 0.8:1:0.3:2.4:1, hydrazine hydrate The volume ratio of solution to n-octane is 1:35.

[0027] Activate 20g of catalyst precursor A in a m...

Embodiment 2

[0029] Mix an appropriate amount of n-octane, n-hexanol and Tween 80 to make a stable microemulsion. Add an aqueous solution containing an appropriate amount of nickel nitrate and ammonium molybdate to the microemulsion, stir well at 40°C, and then add an appropriate amount of 60% Hydrazine hydrate solution, after stirring for 5 hours, add an appropriate amount of hydrogen type ZSM-5 (silica to aluminum ratio of 50, pore volume of 0.23ml / g, specific surface area of 426m 2 / g) Carrier, after stirring for 2h at 80℃, filter, the solid precipitate obtained is washed 4 times with ethanol, then dried at 110℃ for 5h, calcined at 450℃ for 6h, to prepare catalyst precursor A, Ni is calculated as element The weight of the carrier is 3%, and Mo accounts for 2% of the weight of the carrier based on elements; n-octane: n-hexanol: Tween 80: active component nickel: first auxiliary molybdenum = 0.8:1:0.3:2.4:1, hydrazine hydrate The volume ratio of solution to n-octane is 1:35.

[0030] Activ...

Embodiment 3

[0032] Mix an appropriate amount of n-octane, n-hexanol and Tween 80 to make a stable microemulsion. Add an aqueous solution containing an appropriate amount of nickel nitrate and ammonium molybdate to the microemulsion, stir well at 40°C, and then add an appropriate amount of 60% Hydrazine hydrate solution, after stirring for 5 hours, add an appropriate amount of silica (pore volume is 1.06ml / g, specific surface area is 387m 2 / g) Carrier, after stirring for 2h at 80℃, filter, the solid precipitate obtained is washed 4 times with ethanol, then dried at 110℃ for 5h, calcined at 450℃ for 6h, to prepare catalyst precursor A, Ni is calculated as element The weight of the carrier is 3%, and Mo accounts for 2% of the weight of the carrier based on elements; n-octane: n-hexanol: Tween 80: active component nickel: first auxiliary molybdenum = 0.8:1:0.3:2.4:1, hydrazine hydrate The volume ratio of solution to n-octane is 1:35.

[0033] Activate 20g of catalyst precursor A in a hydrogen-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com