Air-jetting rice polisher capable of achieving air intake through axial surface

A technology for rice milling and air intake, which is applied in grain processing, application, and grain pod removal, etc. It can solve the problems of troublesome use and maintenance, poor wind blowing effect, and small air volume in the whitening room, and achieves compact structure and effective Good for whitening and bran removal, good whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

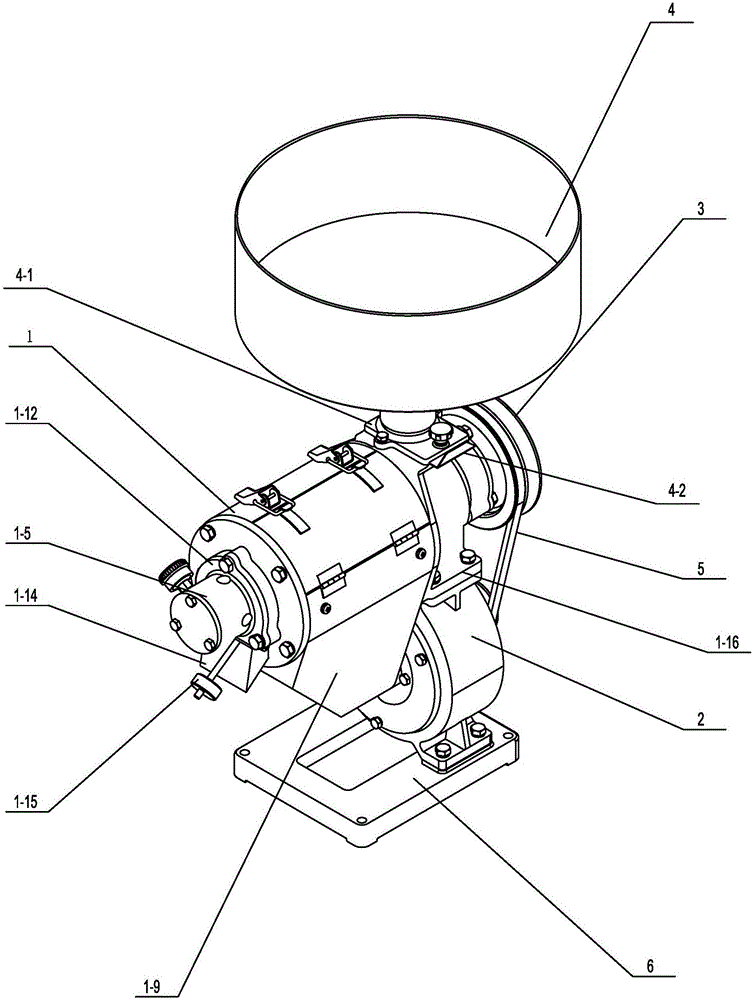

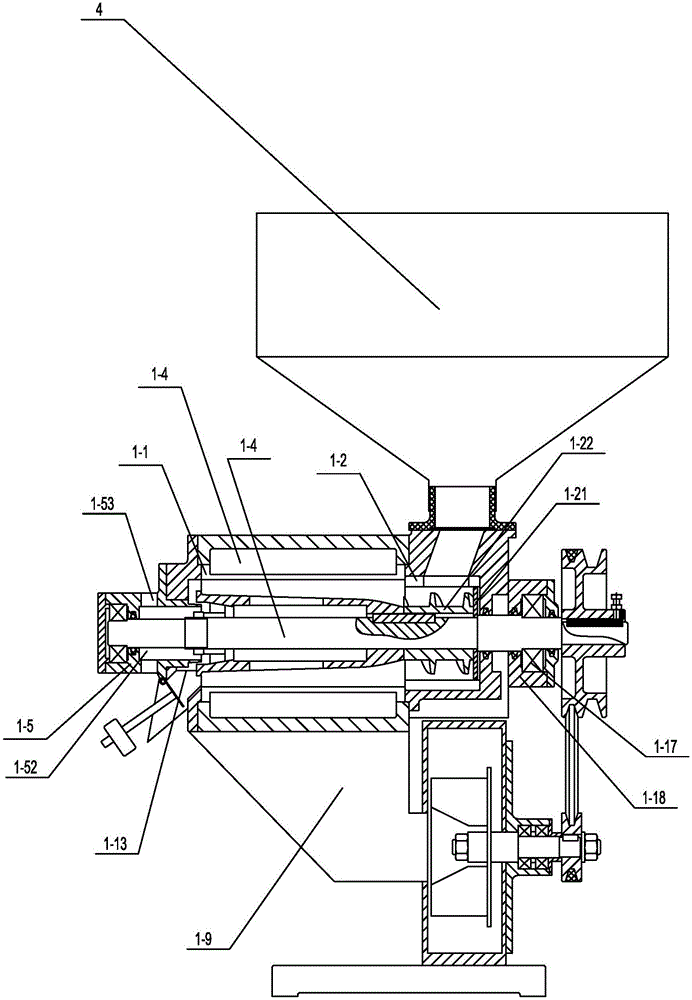

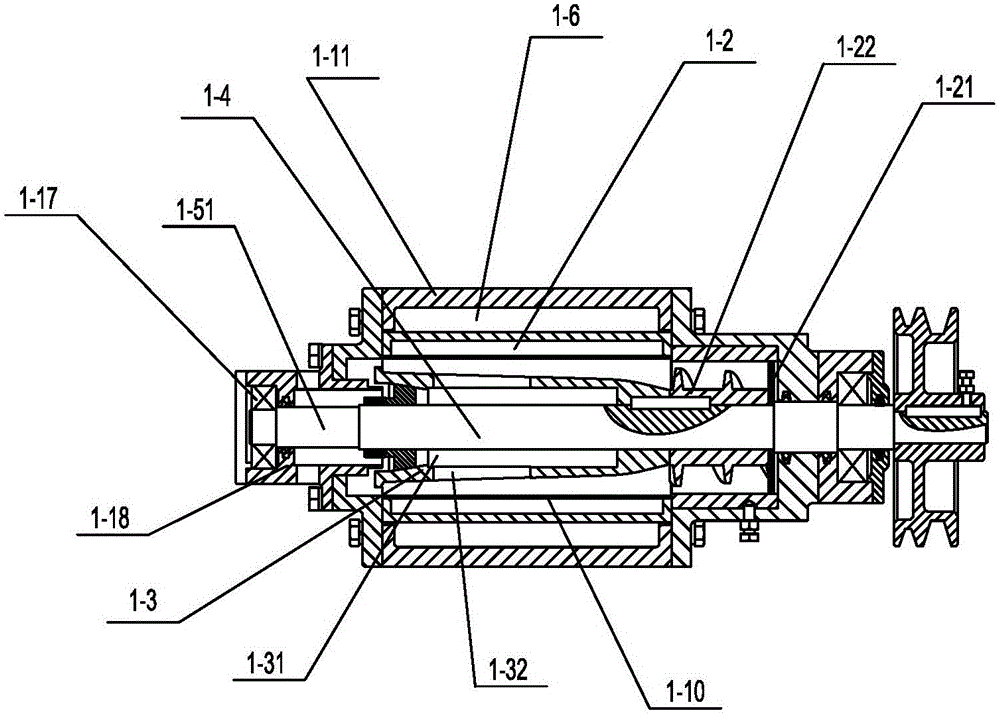

[0025] like figure 1 , figure 2 and image 3 As shown, a kind of specific embodiment of the present invention is proposed, a kind of air jet rice milling machine of axial surface air intake, comprises the rice milling machine book 1 that is provided with rice machine base 1-16 and blower fan 2, described rice milling machine The inner chamber of the body 1 is divided into a whitening chamber 1-1 and a feeding chamber 1-2. The inner chamber of the rice mill body 1 is also provided with a main shaft 1-1 that runs through the whitening chamber 1-1 and the feeding chamber 1-2. 4; the feed chamber 1-2 is connected to the feed hopper 4, the feed hopper 4 is installed on the rice mill body 1 through the feed hopper base 4-1 at the bottom, the feed hopper base Between 4-1 and the feed chamber 1-2, a feed gate 4-2 for controlling the amount of raw grain is provided, and a material retaining plate 1-21 is installed on the front side of the inner chamber of the feed chamber 1-2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com