Liquid-filling pressing forming die for large-medium automotive axle case pipe fitting

A large and medium-sized axle housing technology, which is applied in the field of hydraulic-filled forming moulds for large and medium-sized automobile axle casing pipe fittings, can solve the problems of inability to resist forming force, etc., and achieves the effects of good pipe fitting forming quality, reliable mould structure and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

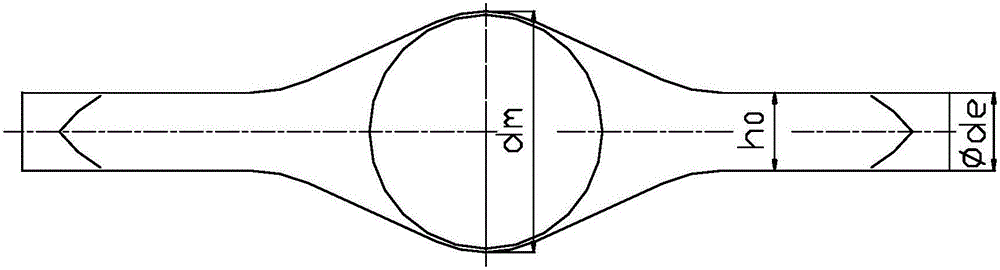

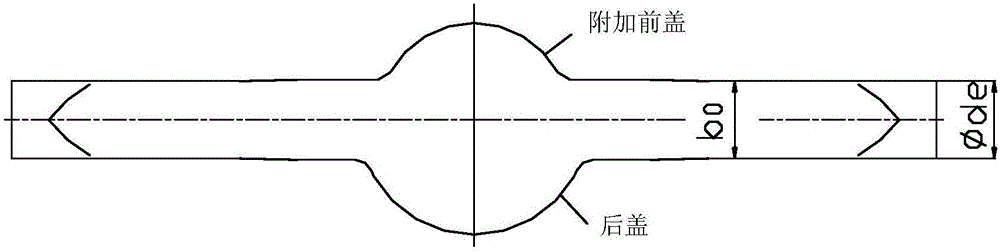

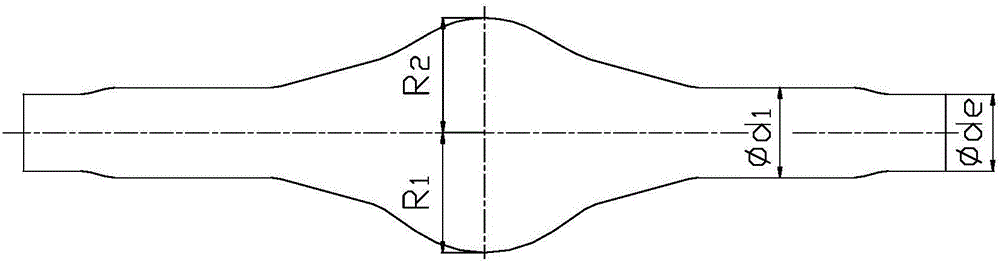

[0034] attached figure 1 , attached figure 2 As shown in the large and medium-sized automobile axle housing pipe fittings, the axle housing pipe fittings are in the shape of a pipa with small middle parts on the left and right sides, and the middle part is an axle bag with a special-shaped cross-section, and has a spherical rear cover and an additional front cover. has a maximum height of d m , both sides of the bridge pack are straight tubes with rectangular section, and its height is h 0 , width b 0 , with diameter d at both ends e The lower side of the bridge package axis in the middle of the preformed tube blank before filling and hydraulic forming is larger than the upper side. In this embodiment, the load of the axle housing tube is 5t, and the maximum height of the middle axle package is d m 320~360mm, the height h of rectangular section straight pipes on both sides of bridge pack 0 110~130mm, width b 0 The diameter of the round tube at both ends is 100-120mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com