Milling device

A connecting rod cover and bottom plate technology, which is applied in positioning devices, clamping devices, metal processing equipment, etc., can solve the problems of increasing production costs of connecting rod manufacturers, and achieve avoidance of design and use, quick clamping, and efficient milling processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

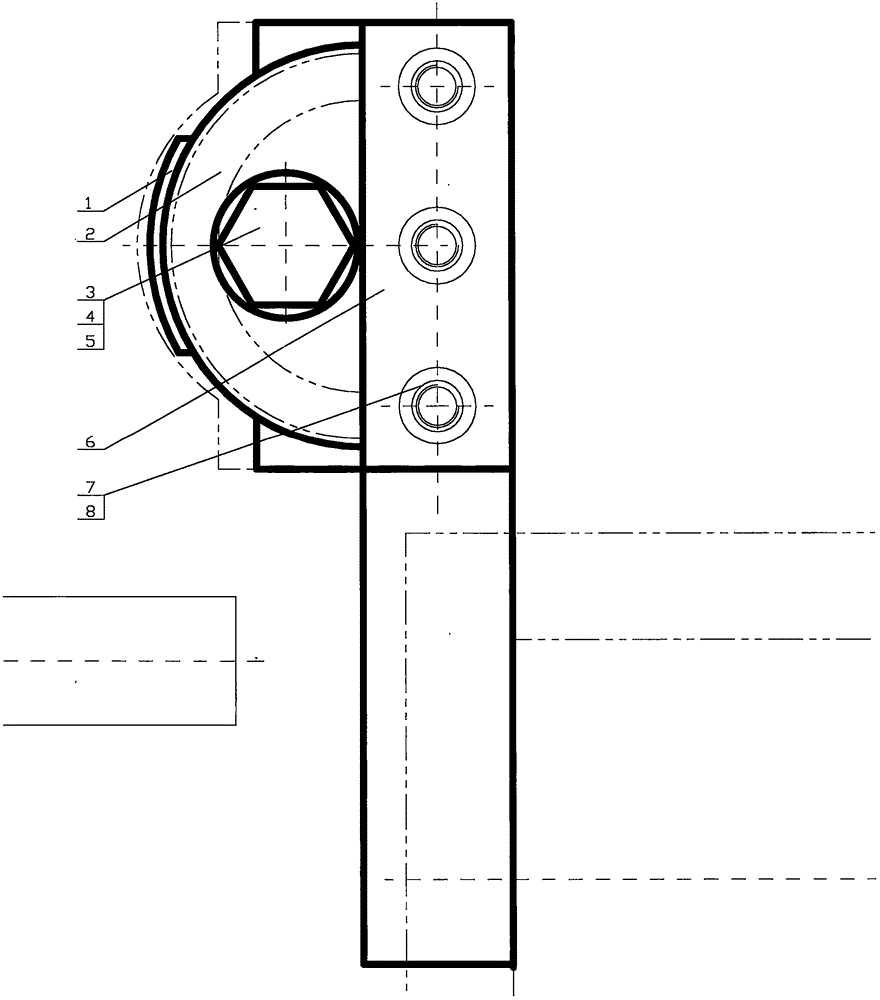

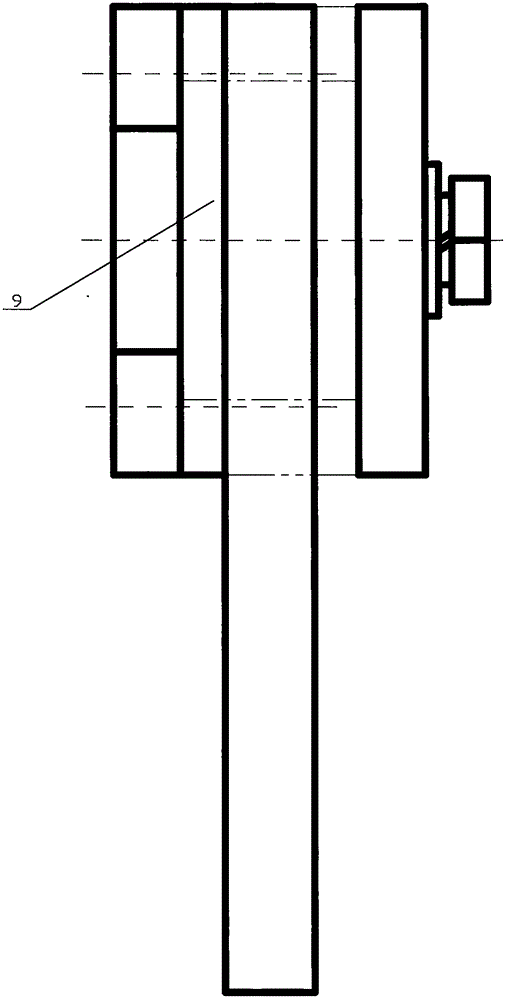

[0010] on the support plate ( figure 1 Middle 6) and bottom plate ( figure 1 In 1) add backing plate ( figure 2 Middle 9), with three M10 hexagon socket head bolts ( figure 1 7) and corresponding spring washers ( figure 1 Middle 8) put the bottom plate ( figure 1 Middle 1) and backing plate ( figure 2 Middle 9) is connected to the support plate ( figure 1 middle 6), put the connecting rod cover on the bottom plate ( figure 1 In 1), the joint surface of the connecting rod cover is close to the support plate ( figure 1 6) on the side of the semicircular cover ( figure 1 Middle 2) Cover the top of the connecting rod cover, use M16 hexagonal bolts ( figure 1 Middle 3), flat pad ( figure 1 4) and corresponding spring washers ( figure 1 Middle 5) Place the semicircular cover plate ( figure 1 Middle 2), connecting rod cover, bottom plate ( figure 1 Middle 1) Tightly connected together, the support plate ( figure 1 Middle 6) It is fixed on the tool holder of the lathe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com