Online replacement method for scraper chain of submerged chain conveyor

A scraper chain and slag scraper technology, applied in conveyors, lighting and heating equipment, transportation and packaging, etc., can solve problems such as unit shutdown, slag scraper shutdown, and threats to the normal operation of the unit, and achieve stable operation, The effect of short replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

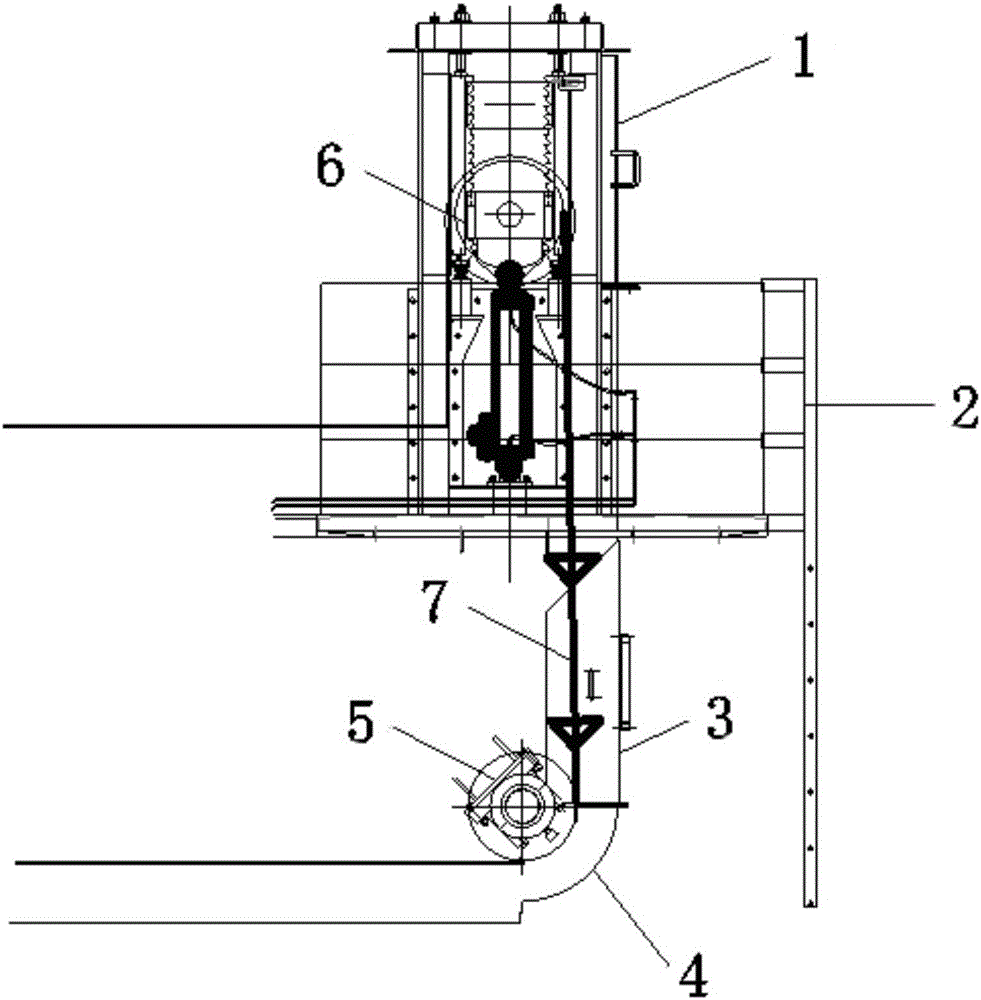

[0013] figure 1 In the process, remove the upper cover plate 1, the stairs 2, and the lower cover plate 3 at the tensioning wheel at the tail of the slag scraper, and cut off the arc-shaped part of the cabin shell 4 near the tail guide wheel to form a scraper chain outlet.

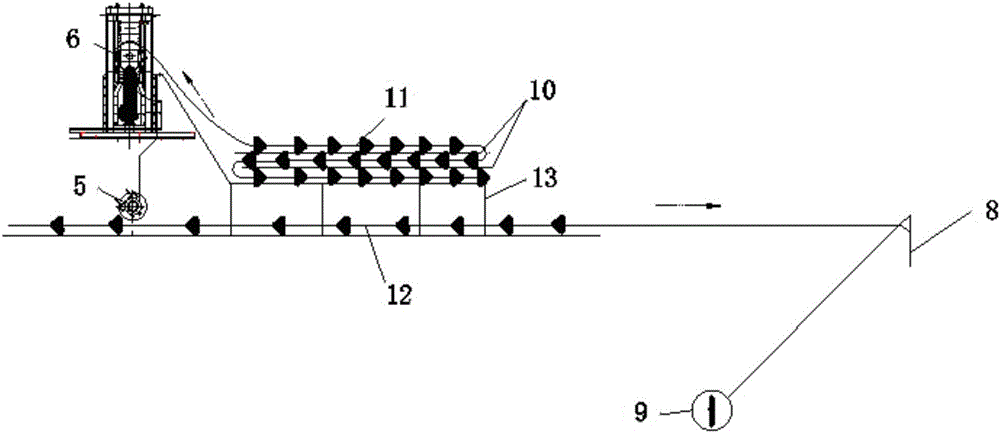

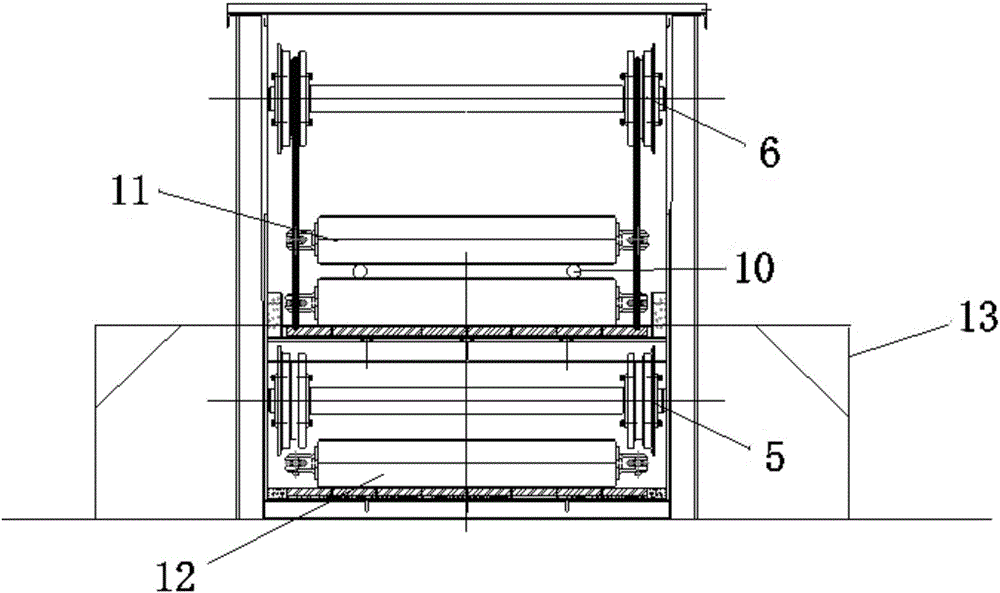

[0014] according to figure 2 , 3 As shown, a new scraper chain placement frame 13 is installed on the outside of the tail of the slag removal machine, and the new scraper chain 11 is stacked on the new scraper chain placement rack 13 according to a few characters, and between layers of the new scraper chain 11 Install two steel pipes 10 of Φ40 between them, according to the situation of the site, arrange the hoist 9 at a suitable position, if the length of the site is not enough, arrange the ground anchor 8 on the central axis outside the tail of the slag removal machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com