Auto diverter for change of direction

A direction conversion and automatic steering technology, applied in the direction of conveyors, rollers, conveyor objects, etc., can solve the problems of inability to change the direction of entry and exit quickly, the support plate is easy to bend, and the rollers are easy to slide up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the direction-changing automatic steering device according to the present invention will be described with reference to the drawings.

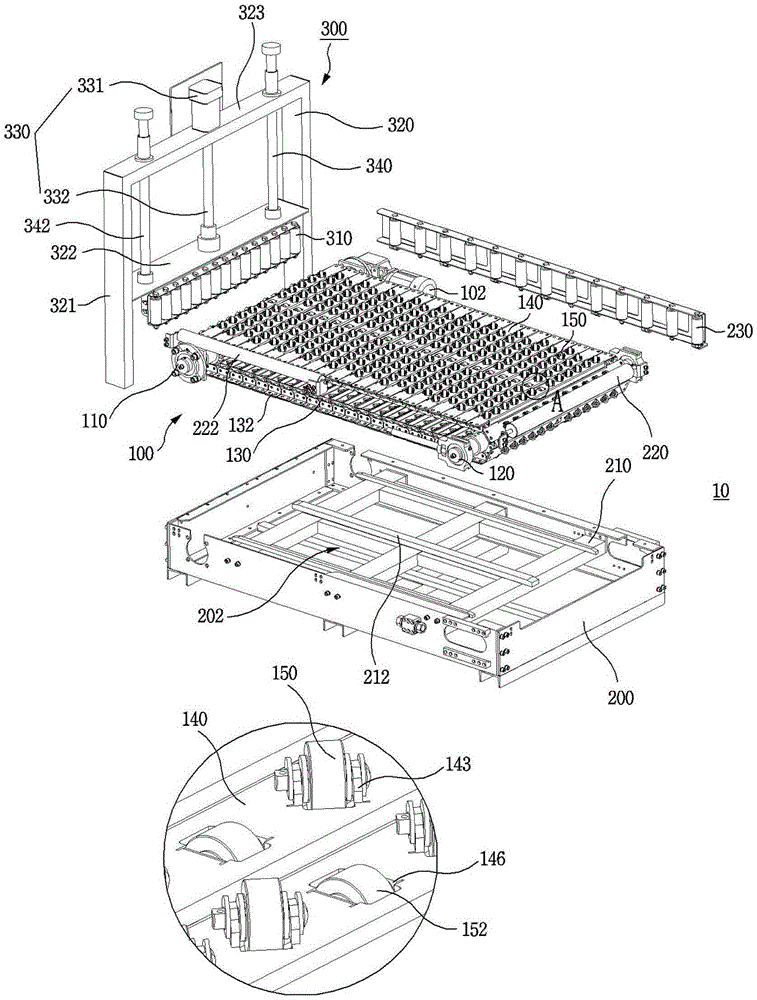

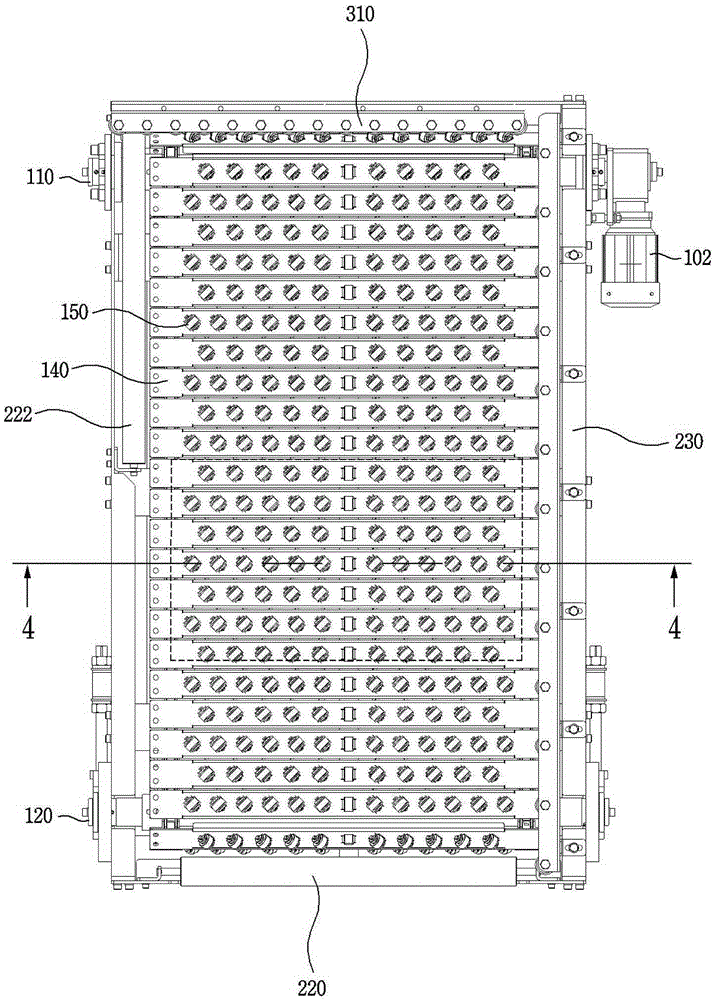

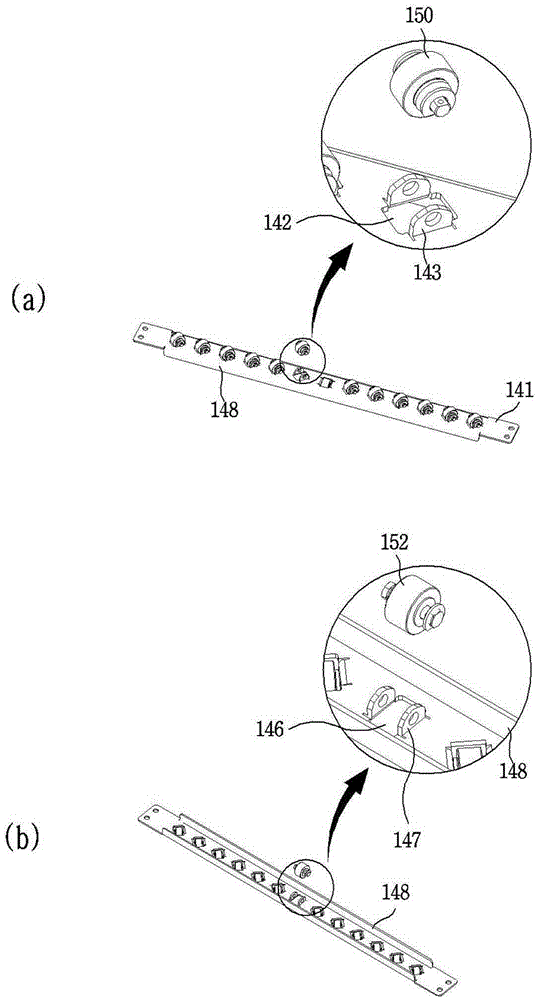

[0037] figure 1 In order to show the exploded perspective view of the direction conversion automatic steering device of the present invention, figure 2 for the floor plan, image 3 For the diagram showing the transfer plate, Figure 4 for figure 2 Sectional view along line 4-4 of the middle transfer plate.

[0038] In the following description, the direction in which the article enters the direction-switching automatic diverter 10 or moves out in a straight line is called the transfer direction, and the direction in which the article moves out of the direction-switching automatic diverter 10 at right angles is called the switching direction.

[0039] The direction changing automatic diverter 10 is composed of a chain transfer unit 100 and a housing 200 , and optionally has an entry and exit control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com