Vertical stereoscopic drainage device for sludge blowing and filling type reinforcement and using method

A drainage device and dredging sludge filling technology, which is applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high moisture content, affecting the construction period, and vacuum load can not effectively transfer the sludge layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

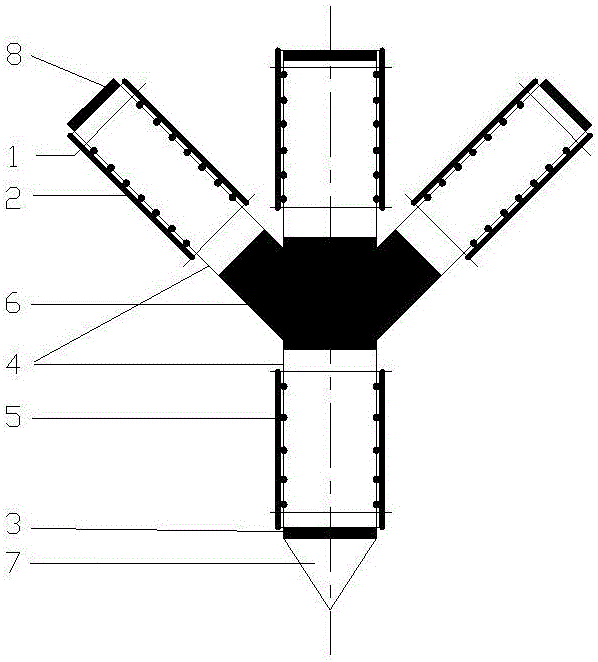

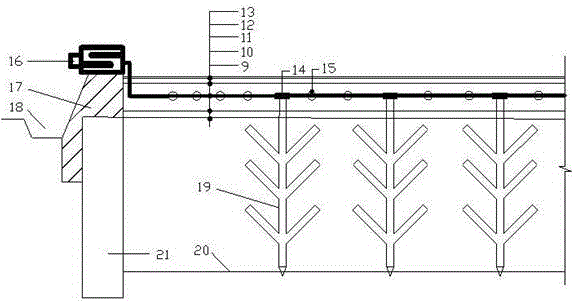

[0024] like figure 1 As shown, the assembly of the vertical three-dimensional drainage device

[0025] (1) Design the PVC pipe 4 with the hole 5 according to the site conditions and the filling depth. For different blow-fill thicknesses, the total length of the vertical three-dimensional drainage device can be adjusted by changing the length of the filter membrane 2 in the uppermost section;

[0026] (2) Order PVC pipe 4 with holes 5, filter membrane 2, nylon cable ties 1, cross 6, connector 3, bottom cover 7, and cover 8 from the manufacturer;

[0027] (3) Set a filter membrane 2 of a certain length on the PVC pipe 4, and fix the filter membrane 2 on the PVC pipe 4 with nylon cable ties 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com