Wheel baffle for lifting and transversely moving equipment

A wheel baffle, lifting and traversing technology, which is applied to the buildings, building types, buildings and other directions where cars are parked, can solve problems such as unfavorable maintenance, maintenance, inconvenient production and installation, and affect the stability of equipment, so as to shorten the maintenance period. Workload, equipment operation safety, and the effect of reducing equipment safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

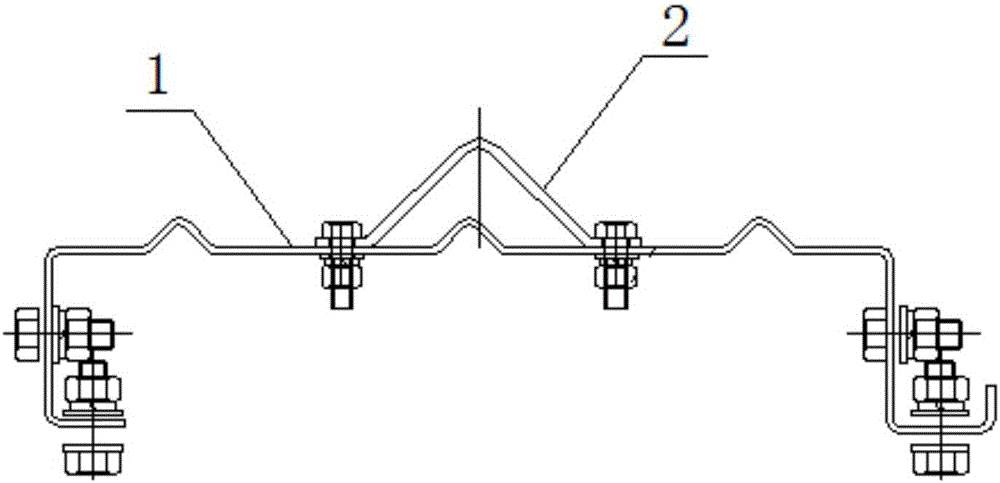

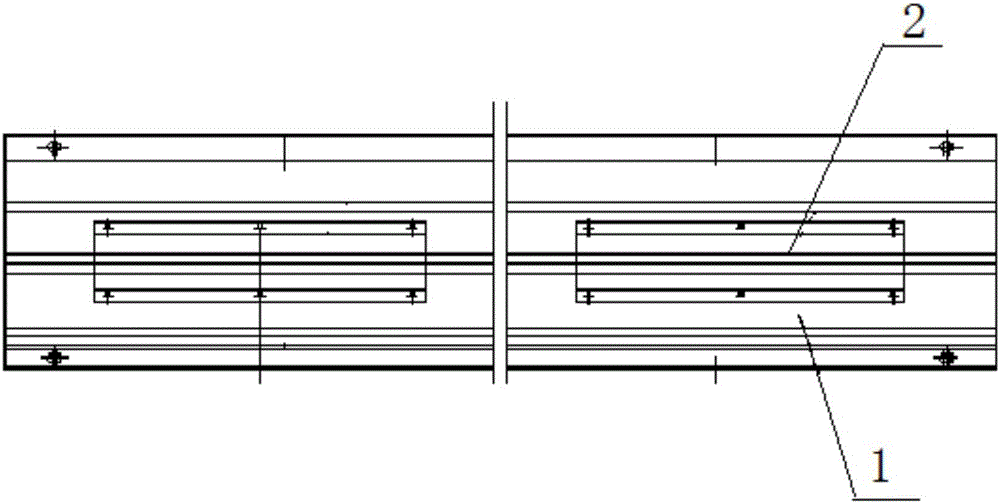

[0016] Such as Figure 1-2 As shown, a wheel baffle for lifting and traversing equipment.

[0017] The wheel baffle used for lifting and traversing equipment includes: a fixed plate 1 and a bent plate 2, wherein there are two bent plates 2, which are respectively connected to both ends of the fixed plate 1 by screws, and the two bent plates The center distance of plate 2 is the same as the wheel track.

[0018] Wherein, the fixing plate 1 is a corrugated plate, and two adjacent wave-shaped protrusions of the corrugated plate are connected by a flat plate; The direction of the side end plates is consistent, and fixing screws are respectively arranged on the two sides of the L shape.

[0019] Wherein, the angle between the two sides of the bent plate is 60 degrees, and the bent plate is provided with a galvanized layer.

[0020] After the equipment debugging is completed, the present invention is fixed on the left and right sides of the corrugated board and connected by ordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com