Swing type multistage electric telescopic cylinder

An electric telescopic and swinging technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of long screw extension, reduce the transmission efficiency of the mechanism, affect the azimuth rotation, etc., achieve novel and reasonable design, easy to promote and use, The effect of high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

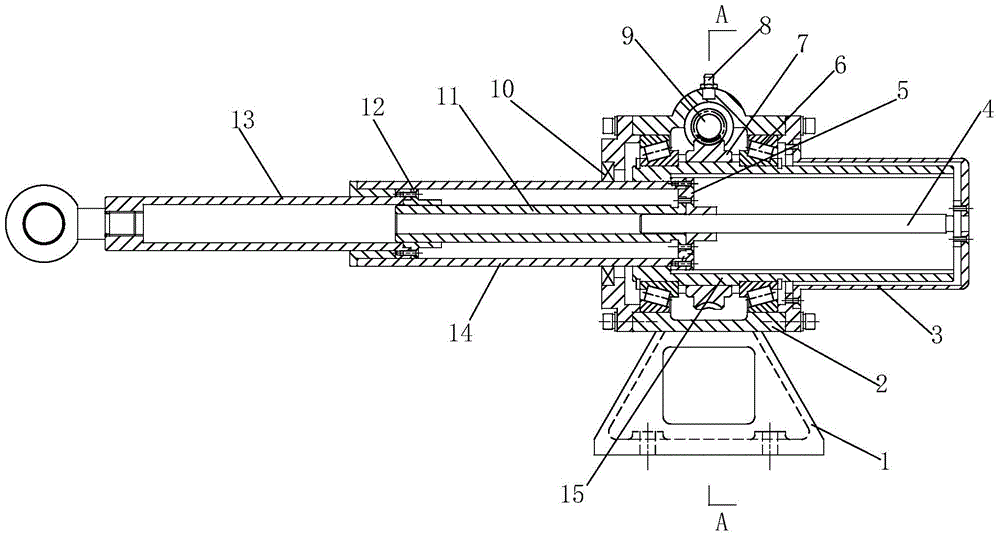

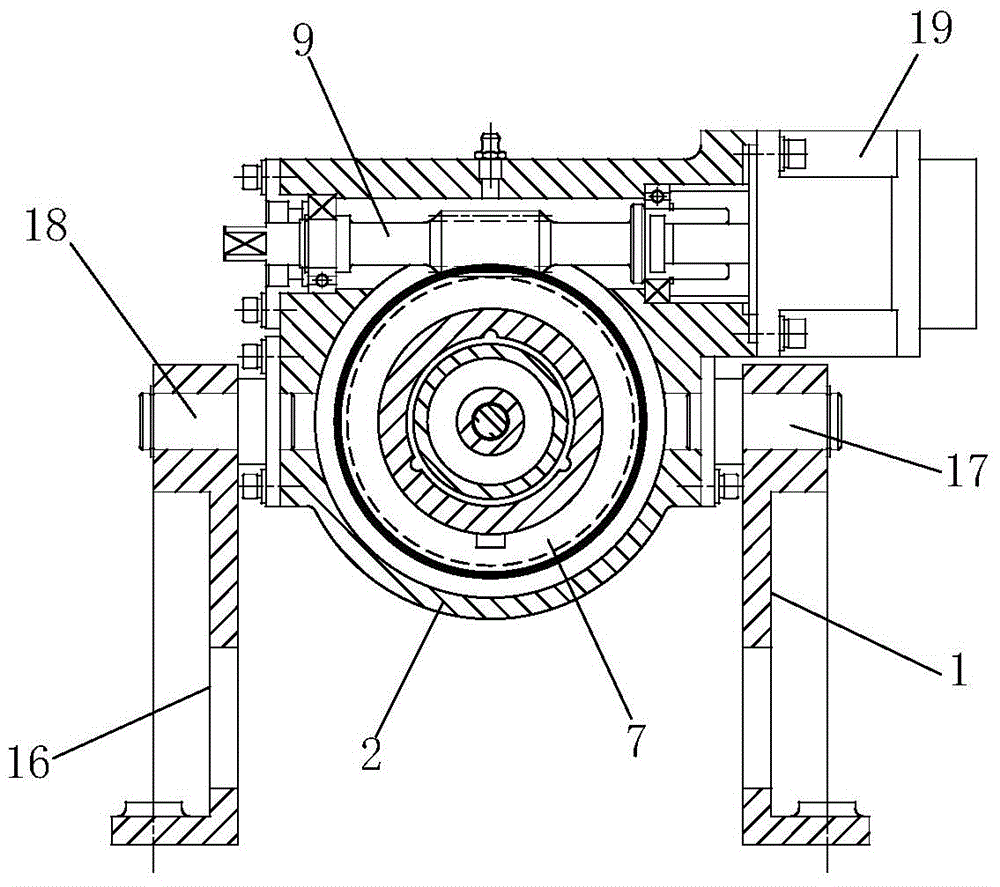

[0028] Such as figure 1 and figure 2 A swing type multi-stage electric telescopic cylinder shown includes a first support 1 and a second support 16, and a housing 2 arranged between the first support 1 and the second support 16, a worm 9, a worm wheel 7 and a worm shaft 15, the housing 2 is rotationally connected with the first bracket 1 through the first rotating shaft 17, the housing 2 is rotationally connected with the second bracket 16 through the second rotating shaft 18, and the worm gear shaft 15 is a cylindrical structure, The worm 9 and the worm wheel 7 are all installed in the housing 2, the housing 2 is connected with a drive motor 19 for driving the worm 9 to rotate, a sleeve 3 is connected to one side of the housing 2, and the worm gear One end of the shaft 15 extends into the housing 2 and rotates with the housing 2, and the other end of the worm shaft 15 extends into the sleeve 3, and the worm shaft 15 is connected with A multi-stage retractable mechanism tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com