A circulating ash removal method suitable for fluidized bed boilers

A fluidized bed boiler and fluidized bed technology, which is applied in the field of boiler equipment ash removal, can solve the problems of small output of circulating fluidized bed boilers, affecting heat transfer efficiency, and poor soot blowing effect, so as to improve soot blowing efficiency and ensure Sand blasting effect, effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

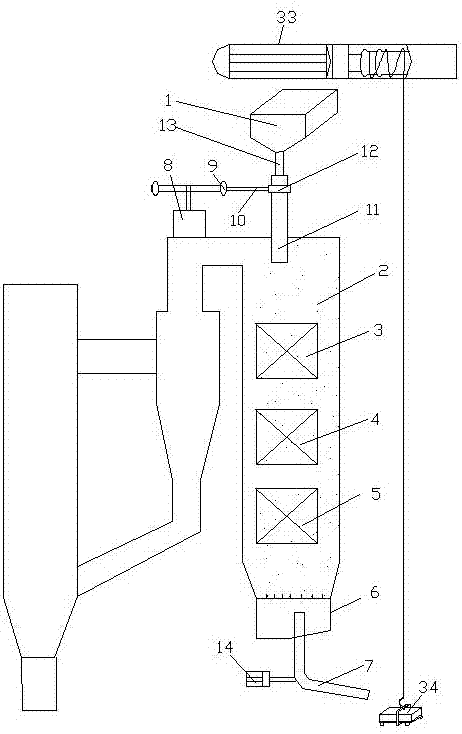

[0067] see figure 1, a circulating ash removal method suitable for fluidized bed boilers, comprising a sand loading step and a recovery step, a sand blasting step is also provided between the sand loading step and the recovery step, and a sand extraction step is also provided after the sand blasting step , the sand loading step refers to putting sand in the sand bucket 1 of the circulating sand soot blowing device; the sand blasting step refers to putting the sand in the sand bucket 1 into the sand blaster of the circulating sand soot blowing device, The sand blaster sprays sand into the tail shaft 2 of the fluidized bed boiler; the recovery step refers to that the sand injected into the tail shaft 2 washes the superheater 3, the economizer 4 and the air preheater 5 and then flows to the circulating sand In the fluidized bed 6 of the soot blowing device, the sand is recovered through the auger 7 connected to the fluidized bed 6; The sand is lifted and moved to the top of the ...

Embodiment 2

[0070] see figure 1 , a circulating ash removal method suitable for fluidized bed boilers, comprising a sand loading step and a recovery step, a sand blasting step is also provided between the sand loading step and the recovery step, and a sand extraction step is also provided after the sand blasting step , the sand loading step refers to putting sand in the sand bucket 1 of the circulating sand soot blowing device; the sand blasting step refers to putting the sand in the sand bucket 1 into the sand blaster of the circulating sand soot blowing device, The sand blaster sprays sand into the tail shaft 2 of the fluidized bed boiler; the recovery step refers to that the sand injected into the tail shaft 2 washes the superheater 3, the economizer 4 and the air preheater 5 and then flows to the circulating sand In the fluidized bed 6 of the soot blowing device, the sand is recovered through the auger 7 connected to the fluidized bed 6; The sand is lifted and moved to the top of the...

Embodiment 3

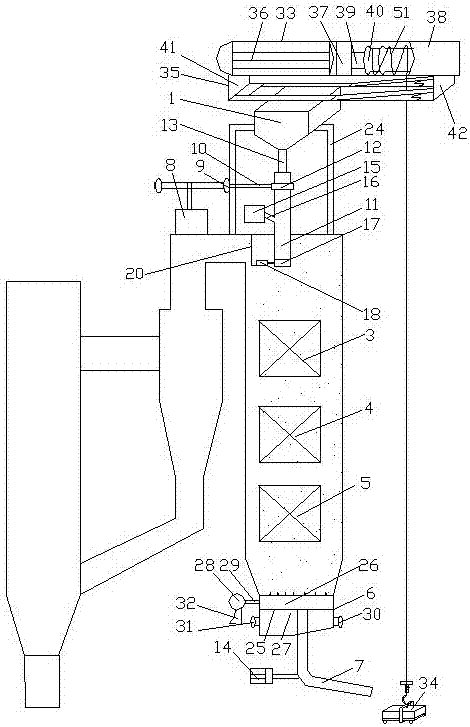

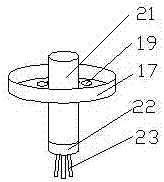

[0077] see figure 2 with image 3 , a circulating ash removal method suitable for fluidized bed boilers, comprising a sand loading step and a recovery step, a sand blasting step is also provided between the sand loading step and the recovery step, and a sand extraction step is also provided after the sand blasting step , the sand loading step refers to putting sand in the sand bucket 1 of the circulating sand soot blowing device; the sand blasting step refers to putting the sand in the sand bucket 1 into the sand blaster of the circulating sand soot blowing device, The sand blaster sprays sand into the tail shaft 2 of the fluidized bed boiler; the recovery step refers to that the sand injected into the tail shaft 2 washes the superheater 3, the economizer 4 and the air preheater 5 and then flows to the circulating sand In the fluidized bed 6 of the soot blowing device, the sand is recovered through the auger 7 connected to the fluidized bed 6; The sand is lifted and moved t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com