Pipe piece elastic sealing gasket water tightness testing method considering soil body influences

A technique of elastic gaskets, test methods, applied in the direction of liquid tightness measurement using liquid/vacuum degree, by detecting the presence of fluid at the leak point, testing material strength using applied stable tension/pressure, etc., can solve the problem of neglecting soil. The influence of granular elastic gaskets, the failure to fully reflect the performance of the segment, the deviation of the critical leakage and opening of the segment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described below in conjunction with accompanying drawing:

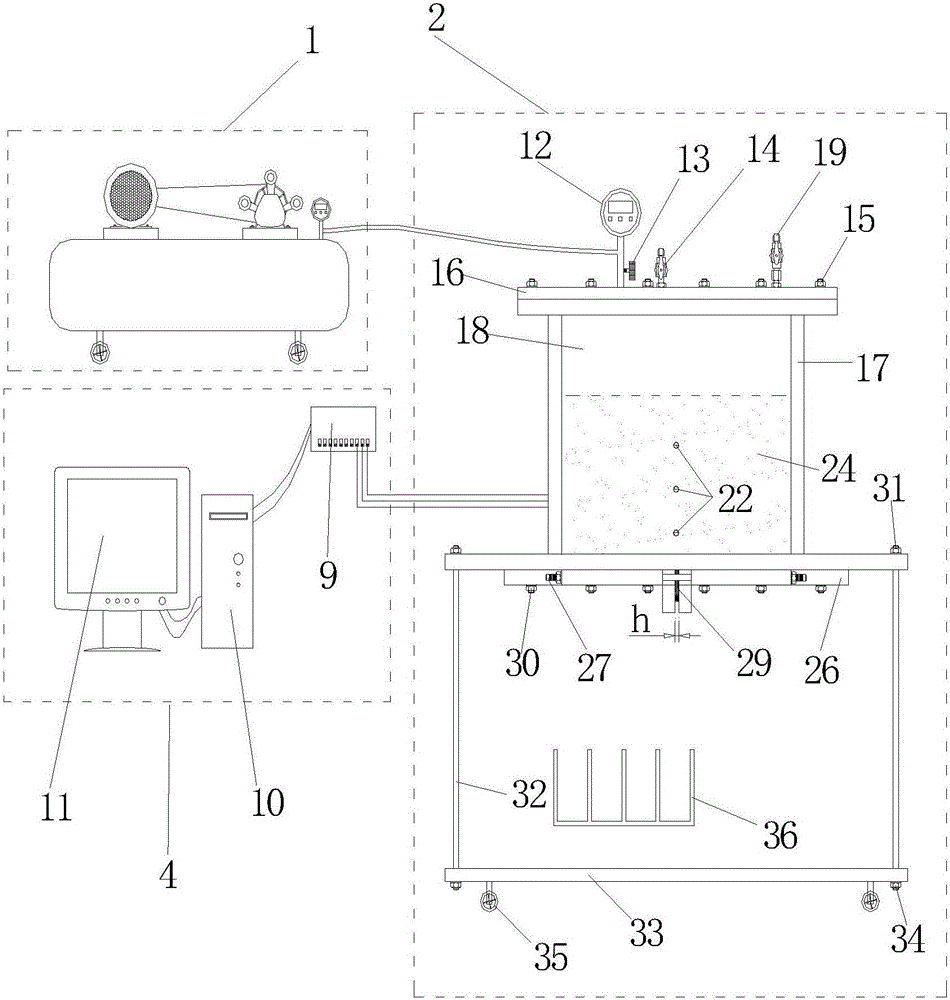

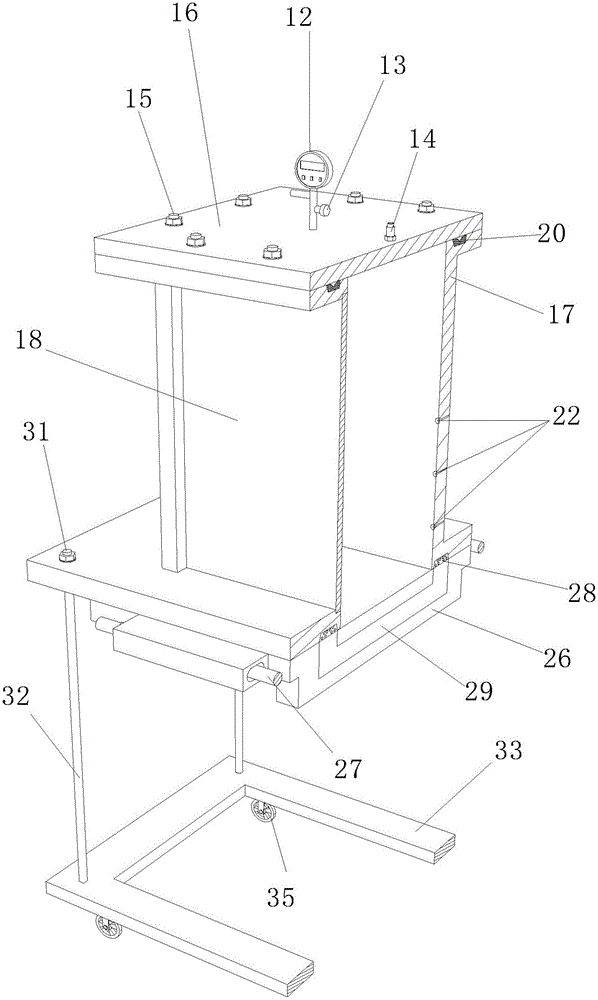

[0027] The required main test system of the present invention is as figure 1 shown, see Figure 1 to Figure 5 , the shield tunnel leakage test system of the present invention with elastic sealing gasket, soil and water, comprising air pump system 1, main test system 2, data acquisition system 4; air pump system 1 and main test system 2 through telescopic pneumatic hose Connection; the data acquisition system 4 is connected with the main test system 2 through data wires.

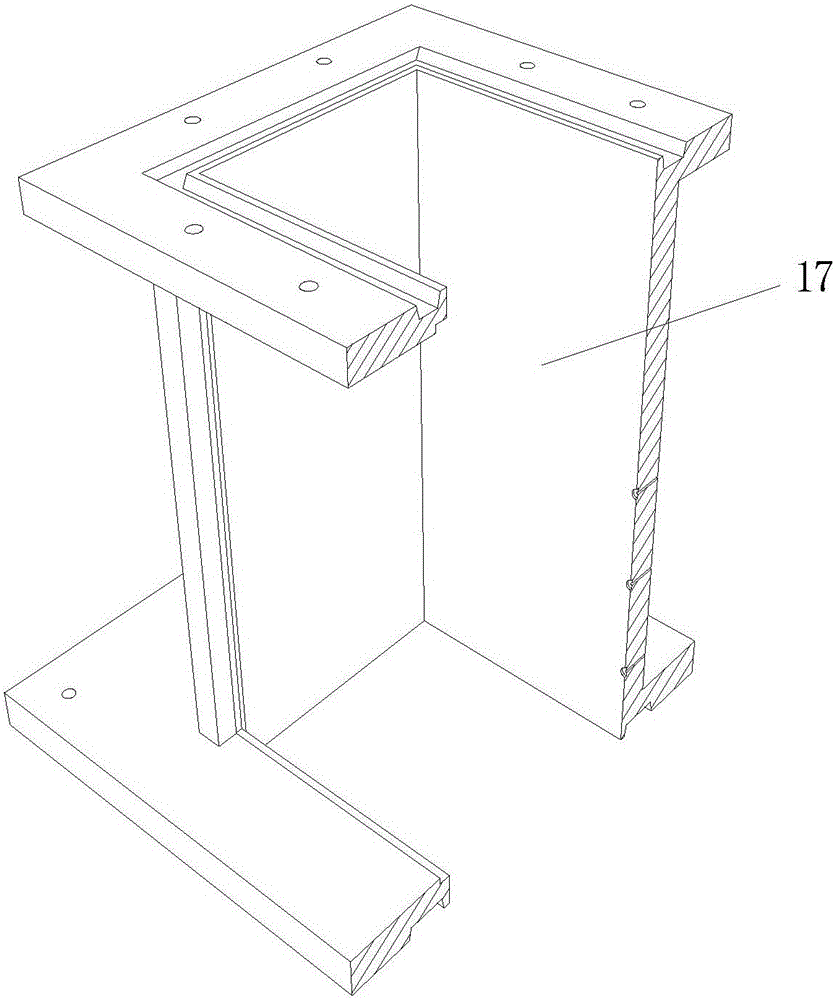

[0028] The main test system includes a digital display pressure gauge 12, a precision pressure regulating valve 13, an air release valve 14, an upper cover plate 16, an upper cover plate bolt 15, a water injection valve 19, a main test box 17, and a miniature pore water pressure gauge 22 , observation window 18, L-shaped adjustable bottom plate 26, bottom plate bolt 30, lead screw 27, main test box lower elastic gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com