Experiment device and testing method of uniaxial BREE solution

A technology of experimental equipment and testing methods, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of lack of experimental testing research, no consideration of temperature, and conservativeness, etc., to achieve convenient experimental research and good engineering value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

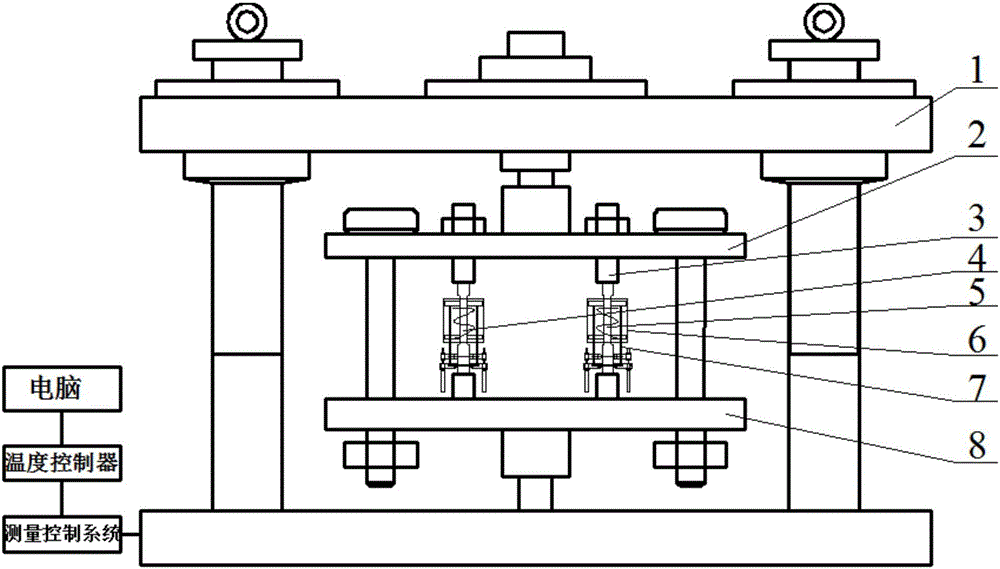

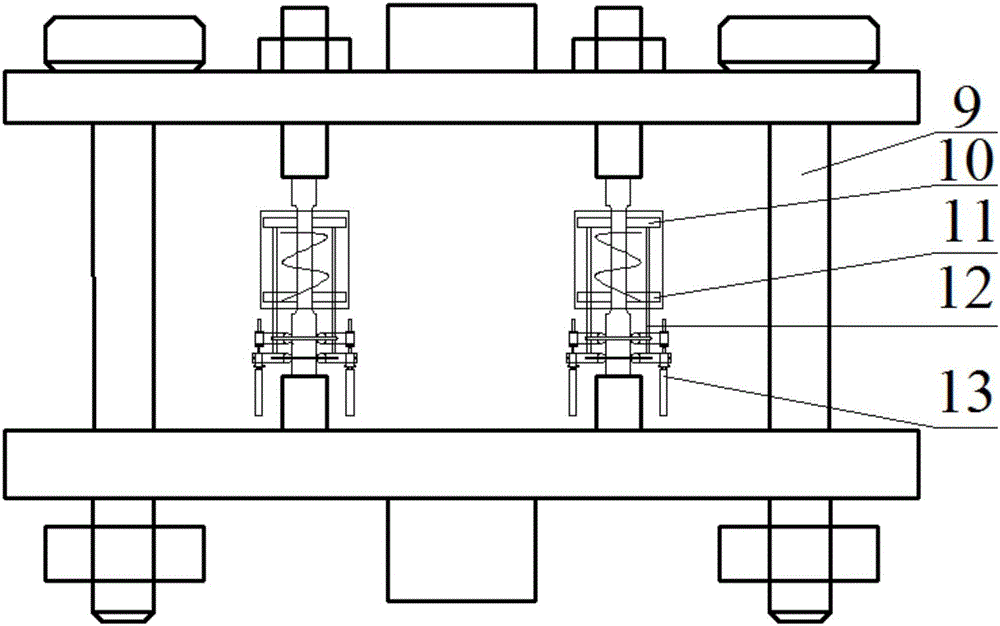

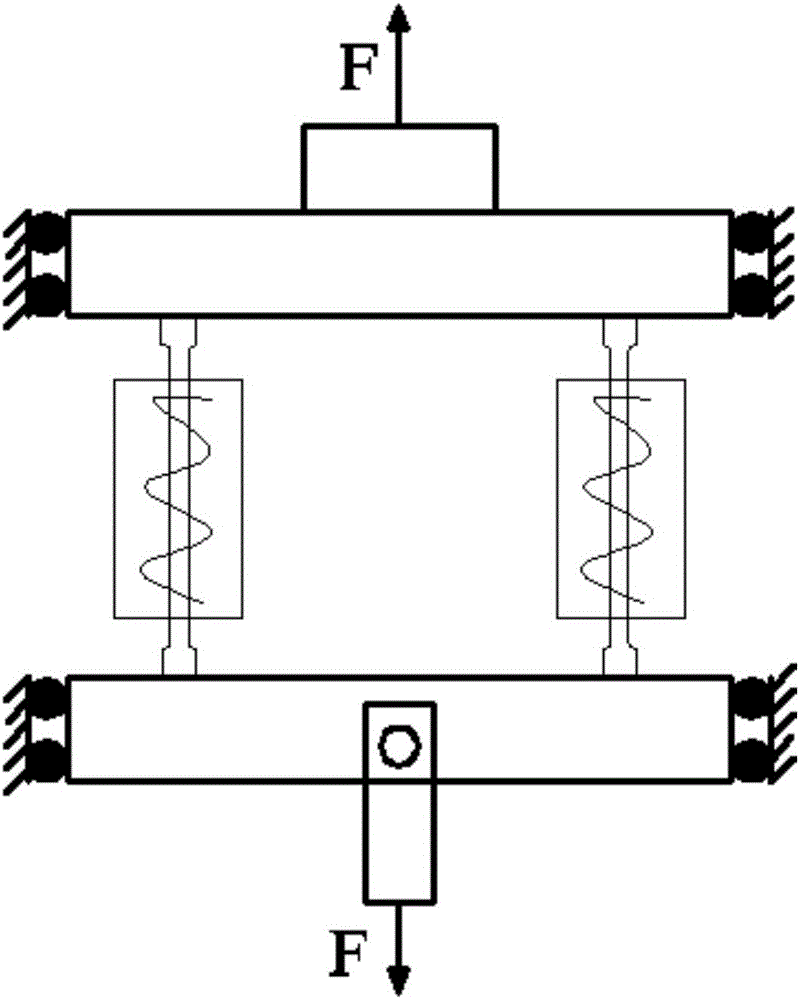

[0026] refer to figure 1 As shown, the experimental device of the uniaxial BREE solution of the present invention mainly includes a high temperature creep fatigue testing machine 1, an upper beam 2, a lower beam 8, a sample holder 3, a first rod sample 4, a second rod Part sample 5, heating furnace 6, high temperature displacement sensor 7, temperature controller and measuring system, high temperature creep fatigue testing machine 1 can be MTS, RPL50, INSTRON and other models, the upper beam 2 and the lower beam 8 pass through the support rod 9 Linked and fixed in the fixture of the high-temperature creep fatigue testing machine 1, two parallel sample fixtures (3) are arranged between the upper beam 2 and the lower beam 8, the first bar sample 4, the second bar T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com