Defect detection equipment and method for boiler water-cooled wall tubes based on low-frequency electromagnetic technology

A water-cooled wall tube and defect detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of inability to detect inner wall defects, low detection efficiency, low measurement accuracy, etc., to achieve the effect of fast detection, fast and accurate detection, and filling technical gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

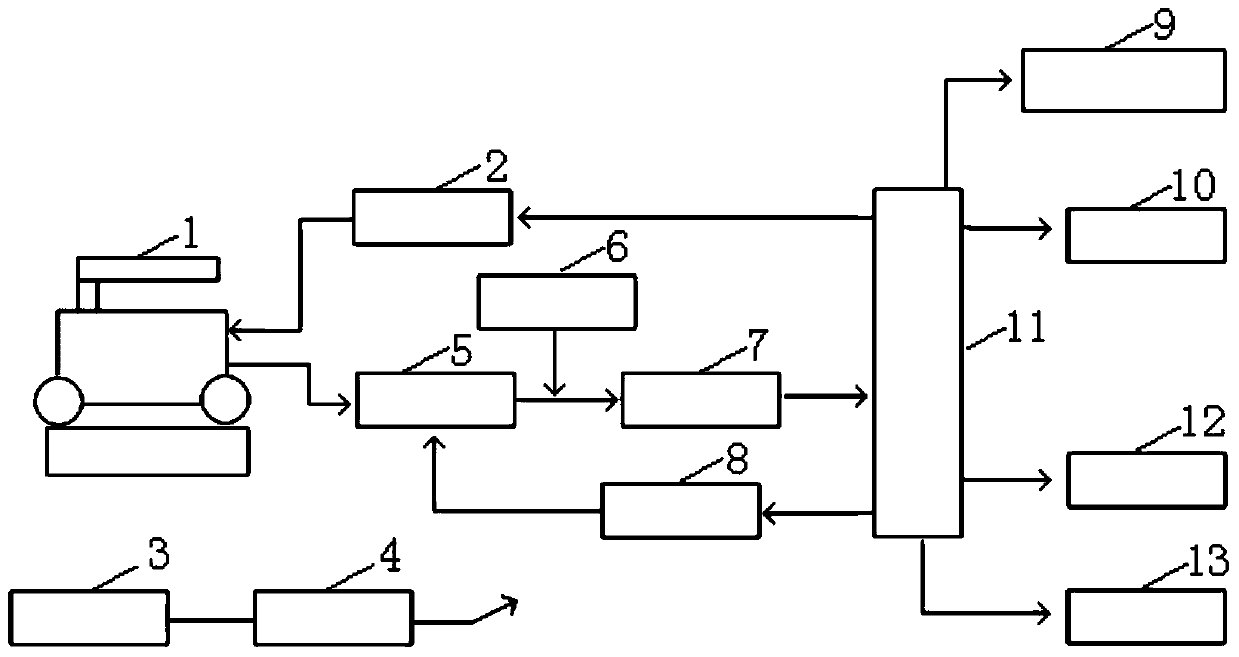

[0018] refer to figure 1 , the defect detection equipment of boiler water wall tube based on low-frequency electromagnetic technology according to the present invention includes a power supply module, a processor 11, a touch screen 10, an exciter 2, and a scanning probe 1, which is used to predict the signal received by the scanning probe 1. The processed signal preprocessing circuit and the power supply module for providing electric energy; the output end of the processor 11 is connected to the input end of the scanning probe 1 through the exciter 2, and the output end of the scanning probe 1 is connected to the input end of the signal preprocessing circuit The processor 11 is connected with the signal pre-processing circuit and the touch screen 10 .

[0019] It should be noted that the signal pre-processing circuit includes a phase shifter 8, a signal amplifier 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com