Pointer type instrument reading method based on machine vision

A technology of instrument reading and machine vision, applied in the field of image monitoring and processing systems, can solve problems such as inability to collect instrument panel images, low efficiency, and instrument image attitude errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

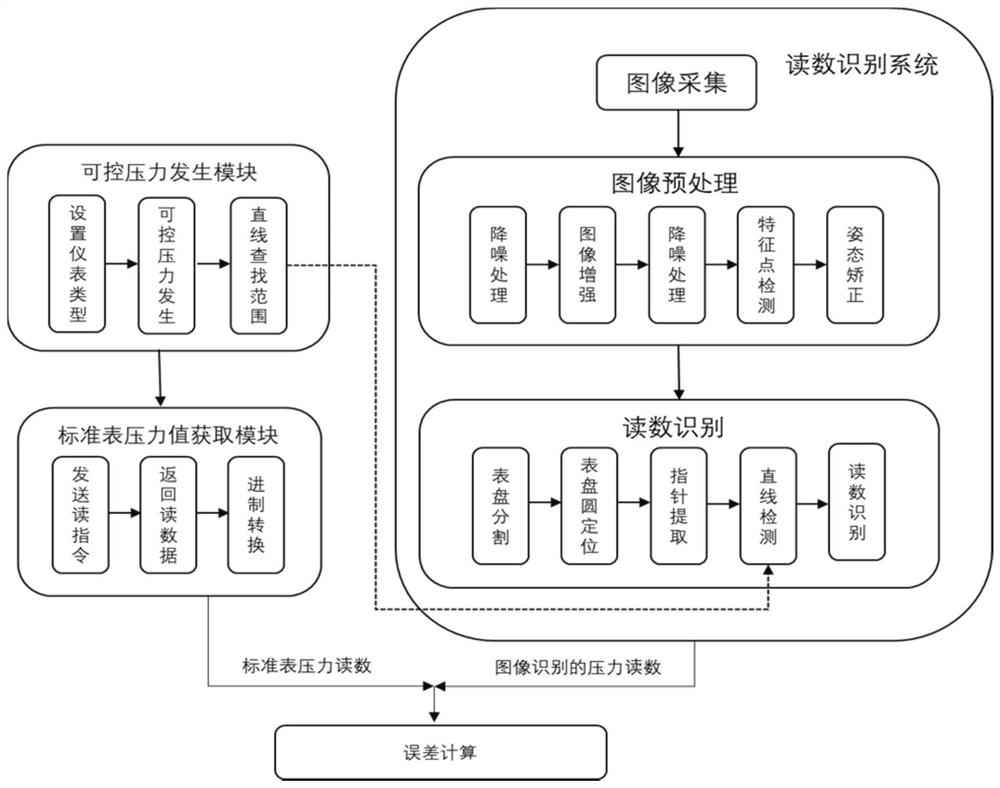

[0046] This embodiment provides a method for reading pointer pressure gauges based on machine vision, such as figure 1 shown, including the following steps:

[0047] (1) Place the standard meter on the plane, use a ring-shaped low-angle light source to illuminate the meter, and use an industrial camera to collect the standard template image of the meter. The standard template image of the meter is as follows figure 2 As shown; place the meter to be read in the same lighting environment as the standard meter, and use an industrial camera to collect the image of the meter to be read;

[0048] (2) Use the feature matching algorithm of the GMS grid motion statistics strategy to perform template matching, and the process is as follows:

[0049] a. The feature points and calculation descriptors of the standard template image of the detection instrument and the image of the instrument to be read;

[0050] b. Match the feature points and calculation descriptors of the instrument st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com