An optical fiber uniform stress applying device

A technology of uniform stress and device application, which is applied in the direction of installation, optics, optical components, etc., can solve the problems of shallow modulation depth, uneven force, easy to break the optical fiber, etc., and achieve the effect of avoiding damage, ensuring accuracy, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

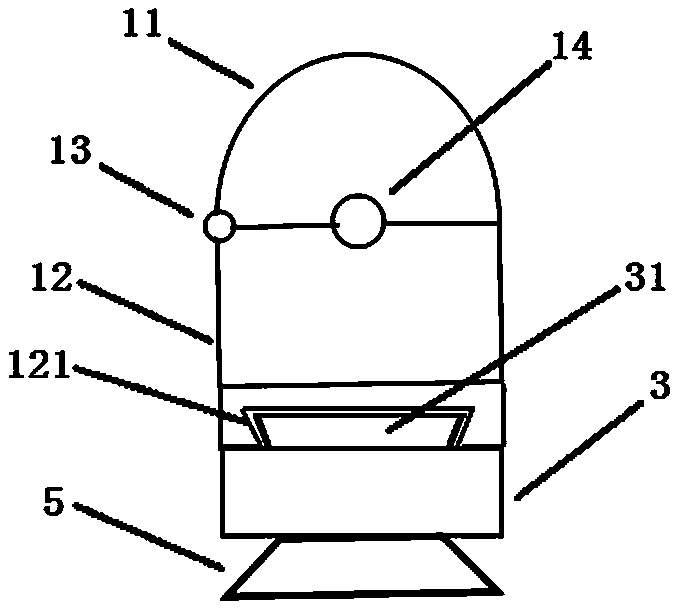

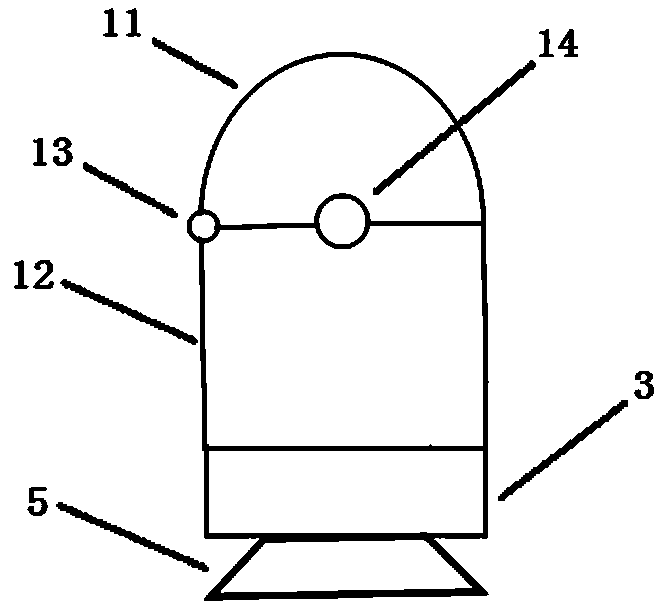

[0020] In order to solve the problem that the optical fiber is easily broken, shaken and tilted by using heavy objects in the optical fiber experiment in the prior art, the present invention provides an optical fiber uniform stress applying device, through the optical fiber clamp and the elastic deformation member moving along the linear slide rail , instead of the optical fiber rack and heavy objects in the prior art, it ensures that the stress on the optical fiber is continuous and uniform, so that the optical fiber does not break and is in a stable and reliable stretching state.

[0021] The present invention will be further described below in conjunction with accompanying drawing.

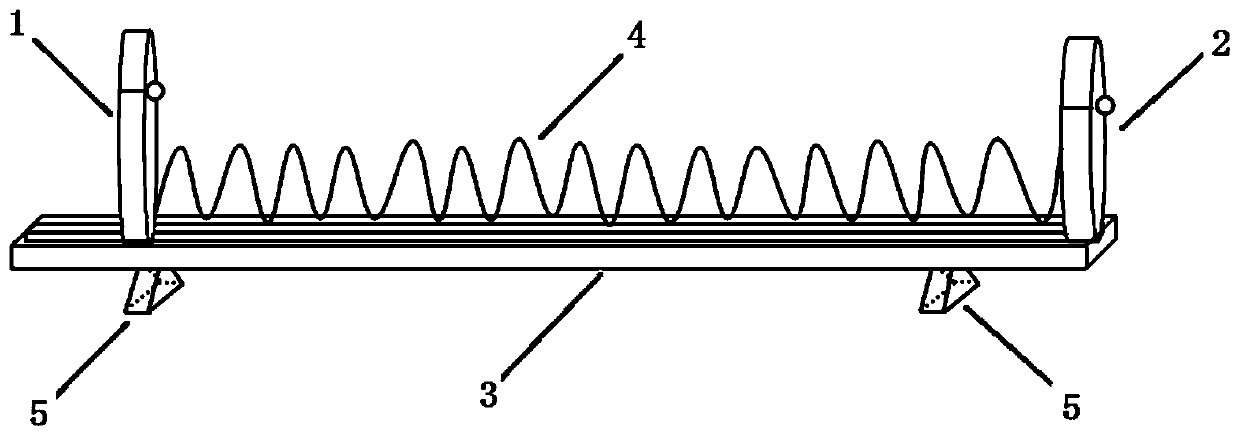

[0022] An optical fiber uniform stress application device, comprising an optical fiber clamp 1, an elastic deformation member 4, a fixed frame 2 and a linear slide rail 3, the optical fiber clamp 1 and the fixed frame 2 are respectively fixed at opposite ends of the linear slide rail 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com