A kind of electronic touch screen and coating preparation process

A preparation process and touch screen technology, which is applied in ion implantation plating, metal material coating process, sputtering plating, etc., can solve the problem of uncoordinated and uniform overall color tone, small actual screen size, and inconsistent color of LCD screen and other issues, to achieve the effect of improving coordination and aesthetics, grand appearance, and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

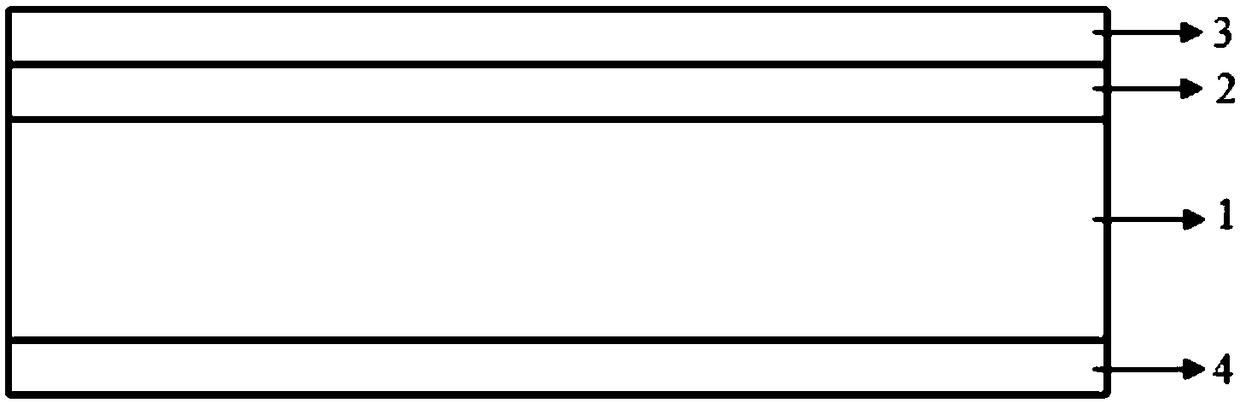

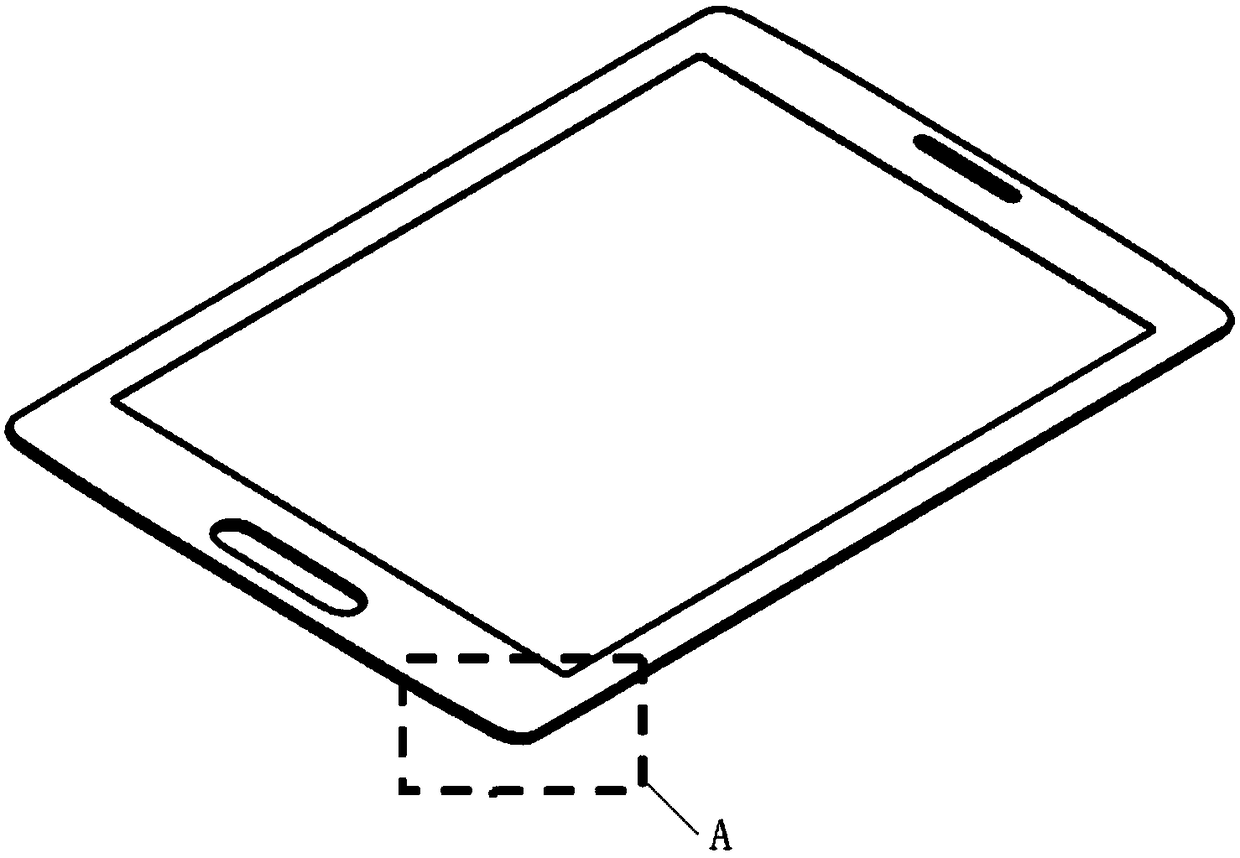

[0038] refer to figure 1 , in one embodiment, an electronic touch screen, comprising a glass cover, the glass cover comprising a glass cover substrate 1, an optical coating covering the inner surface of the glass cover substrate 1 Layer 2, the ink silk screen printing layer 3 covered on the inner surface of the optical coating layer 2, wherein the optical coating layer 2 and the ink silk screen printing layer 3 are located in the screen edge area outside the screen visible area of the glass cover . Through the configuration of the optical coating layer 2 and the ink screen printing layer 3 located in the screen edge area of the glass cover plate, the screen edge area of the glass cover plate of the mobile phone and the liquid crystal screen can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com