Bearing capacity reduction factor of an axially compressed cylindrical shell structure and its determination method

A reduction coefficient and determination method technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of poor reliability of the reduction coefficient, achieve structural weight reduction, ensure safety and reliability, and improve calculation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

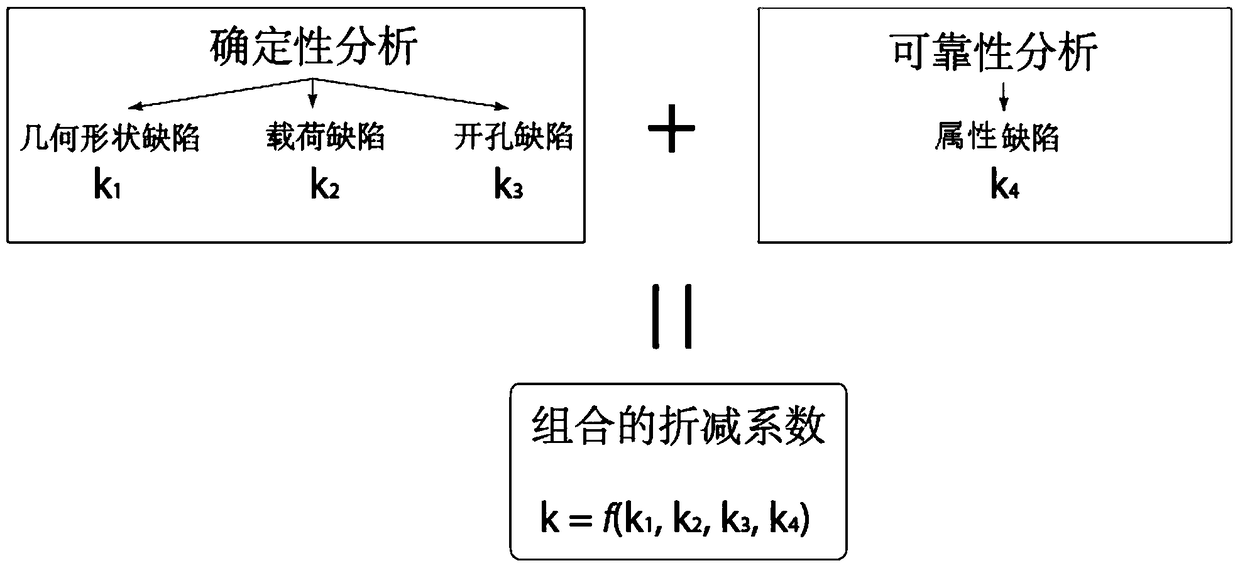

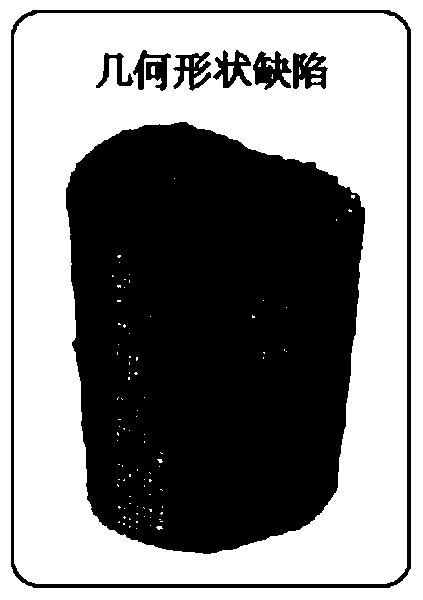

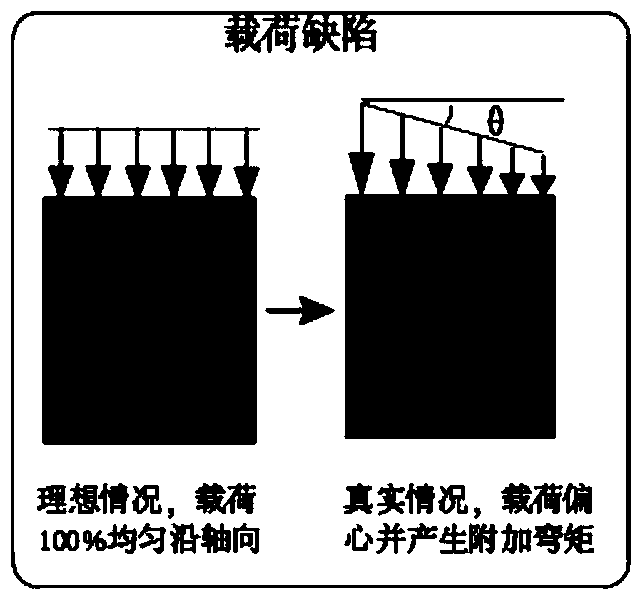

[0061] Such as figure 1 As shown, a bearing capacity reduction factor of an axially compressed cylindrical shell structure, the bearing capacity reduction factor k includes the geometric shape defect reduction factor k 1 , the bearing capacity reduction factor k also includes the load defect reduction factor k 2 , Opening defect reduction factor k 3 and attribute defect reduction factor k 4 , the attribute defect reduction factor k 4 Including the reduction factor caused by material defects and the reduction factor caused by thickness defects.

[0062] The bearing capacity reduction factor k=k 1 ×k 2 ×k 3 ×k 4 .

[0063] A method for determining the reduction factor of the bearing capacity of an axially compressed cylindrical shell structure, the steps are as follows:

[0064] (1) Using the finite element numerical algorithm to analyze the buckling eigenvalues of the defect-free ideal cylindrical shell structure, and obtain its ideal ultimate bearing capacity F per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com