Micro-electro-mechanical system nuclear battery

A technology of micro-electromechanical systems and nuclear batteries, applied in piezoelectric devices/electrostrictive devices, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as limited electric energy and achieve efficient power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

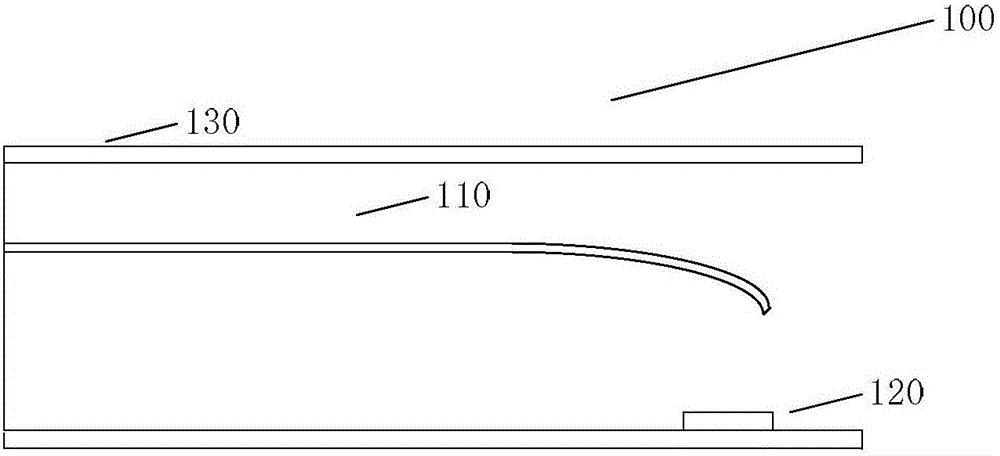

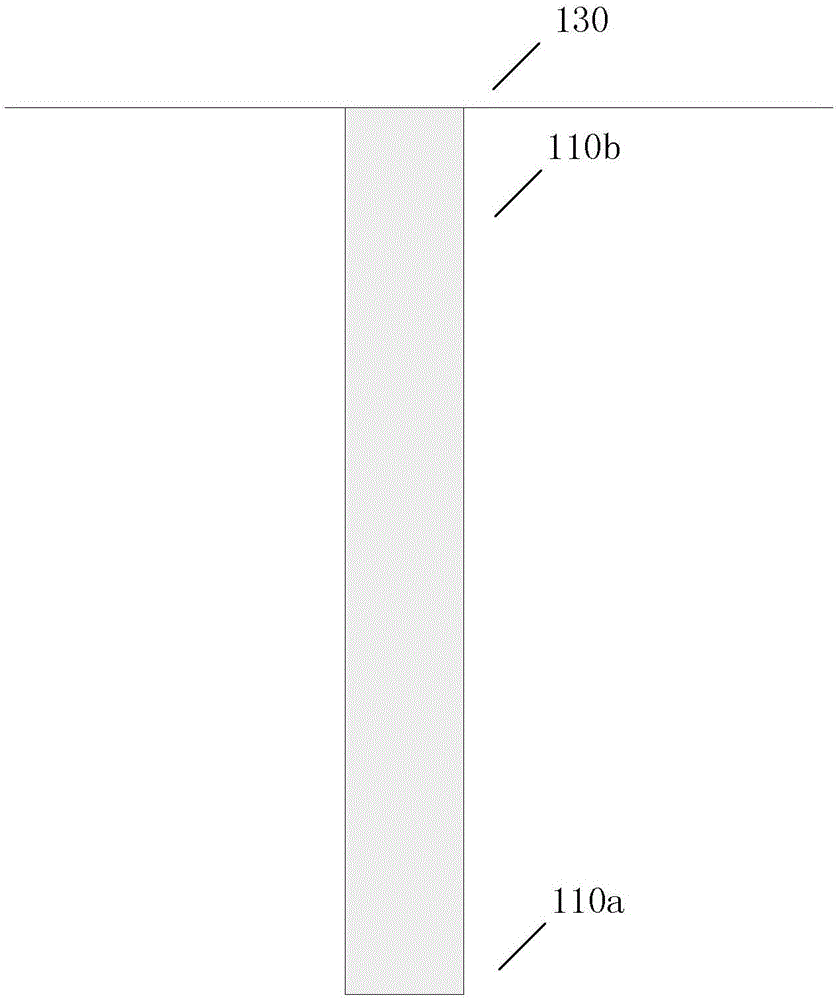

[0026] The present invention will be specifically described below with reference to the accompanying drawings.

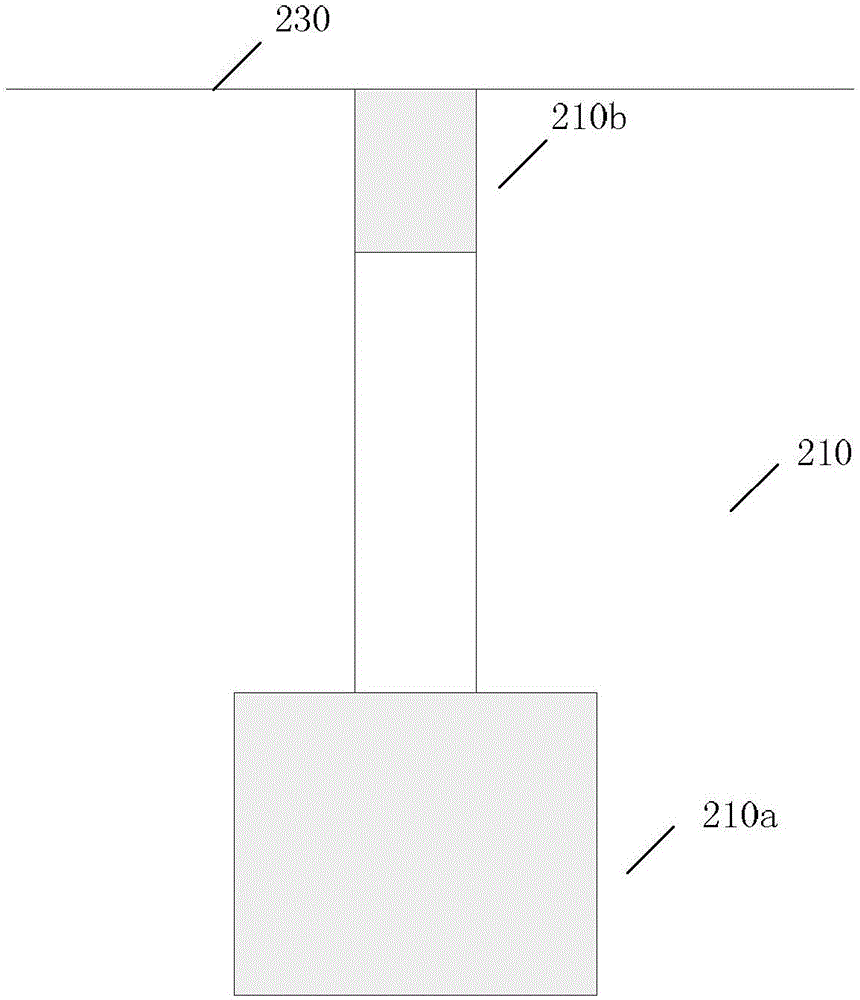

[0027] figure 2 A schematic diagram of the shape of the cantilever beam structure 210 in the MEMs nuclear battery 200 according to an embodiment of the present invention is shown. Other parts of the MEMs nuclear battery 200 according to the embodiment can refer to the structure shown in FIG. 1 .

[0028] Specifically, the MEMS nuclear battery 200 according to the embodiment includes a base 230 (only the side walls of the base are shown), a cantilever beam structure 210, and a radiation unit ( figure 2 not shown). The cantilever beam structure 210 is suspended and fixed to the side wall of the base through a fixed end. The cantilever beam structure 210 includes a radial portion 210a and a piezoelectric portion 210b. The radiation part 210 a is located at the free end of the cantilever beam structure 210 , and the piezoelectric part 210 b is located at the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com