Direct current output switch circuit

A switching circuit, DC output technology, applied in circuit devices, battery circuit devices, current collectors, etc., can solve the problems such as the failure of the relay withstand voltage to be more than 1300V, the large current of the battery pack, and the increase of safety hazards, so as to save costs. , The effect of preventing current backflow and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

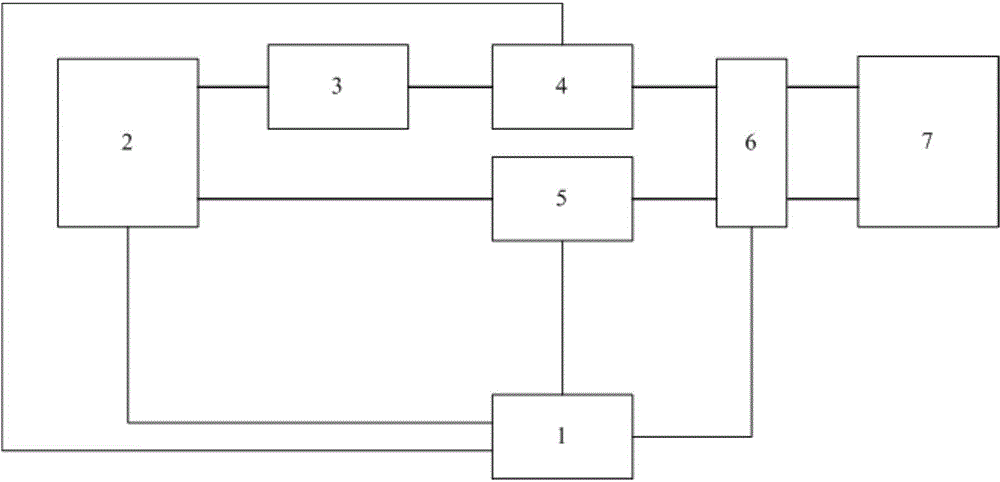

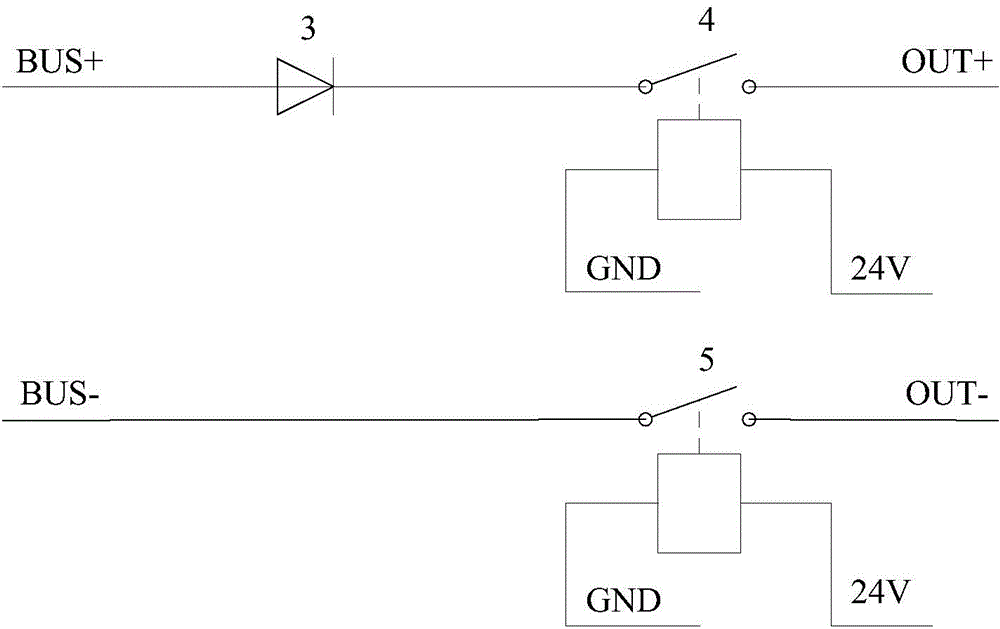

[0022] like figure 1 , figure 2 As shown, a DC output switching circuit includes a busbar (BUS) and an output interface (OUT) connected to the battery pack 7, the rated current of the busbar is 30A, the DC voltage is 1300V, and an anti-reverse 二 Pole tube 3, DC relay 2, first relay 4, second relay 5, voltage detector 6 and main controller 1, DC relay 2 is set at the input end of the bus bar, and the positive pole of the anti-reverse diode 3 is connected to the positive pole and negative pole of the bus bar Connect one end of the normally open point of the first relay 4, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com