Drum filter capable of enabling medical intermediate catalysts to be produced conveniently

A catalyst and filter technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problems of large rotation resistance of the machine, difficulty in unloading the filter cake, scraper wear, etc., and achieves extended service life and simple structure. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

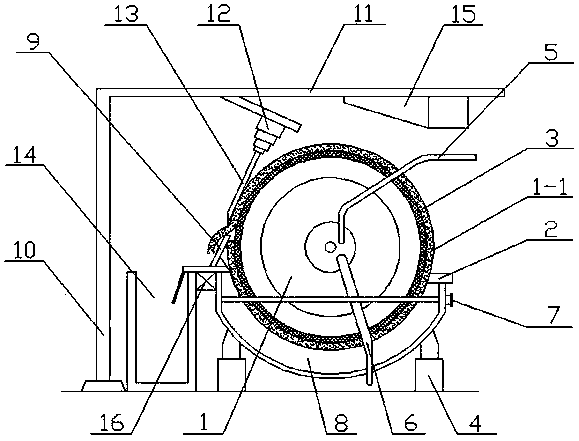

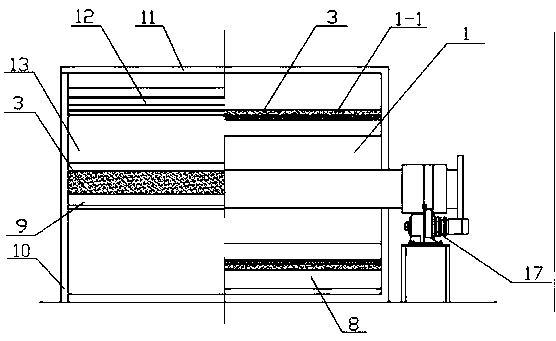

[0017] As shown in the figure, a drum filter that facilitates the production of pharmaceutical intermediate catalysts includes a drum 1, a frame 2 and a motor. The middle of the drum 1 is provided with a pressure pipe 5 and a liquid outlet pipe 6. A feed pipe 7 is provided, the frame 2 is installed on the base 4, the surface of the drum 1 is provided with a filter cloth 1-1, and the filter cake 3 filtered out by the filter cloth 1-1 is placed on the drum The middle of one end of 1 is cut off by the lower scraper 9 and introduced into the feed bin 14. A slurry tank 8 is provided between the bottom end of the drum 1 and the frame 2, and a vertical shaft standing on the ground is provided outside the feed bin 14. Support 10, the top of the vertical support 10 is connected to the horizontal horizontal support 11, the horizontal sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com