Overflow valve for a fuel injection system, and fuel injection system

A fuel injection system and injection system technology, applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as overflow valve rigidity, spring chamber overfilling, etc., to achieve leakage and simple cost , easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

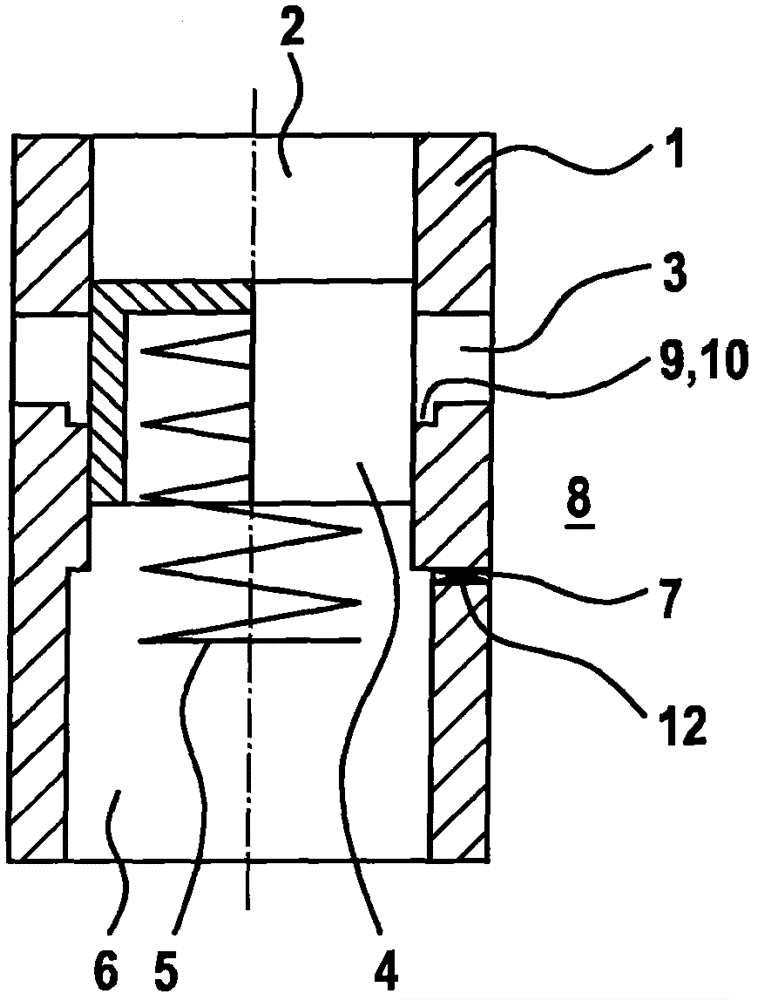

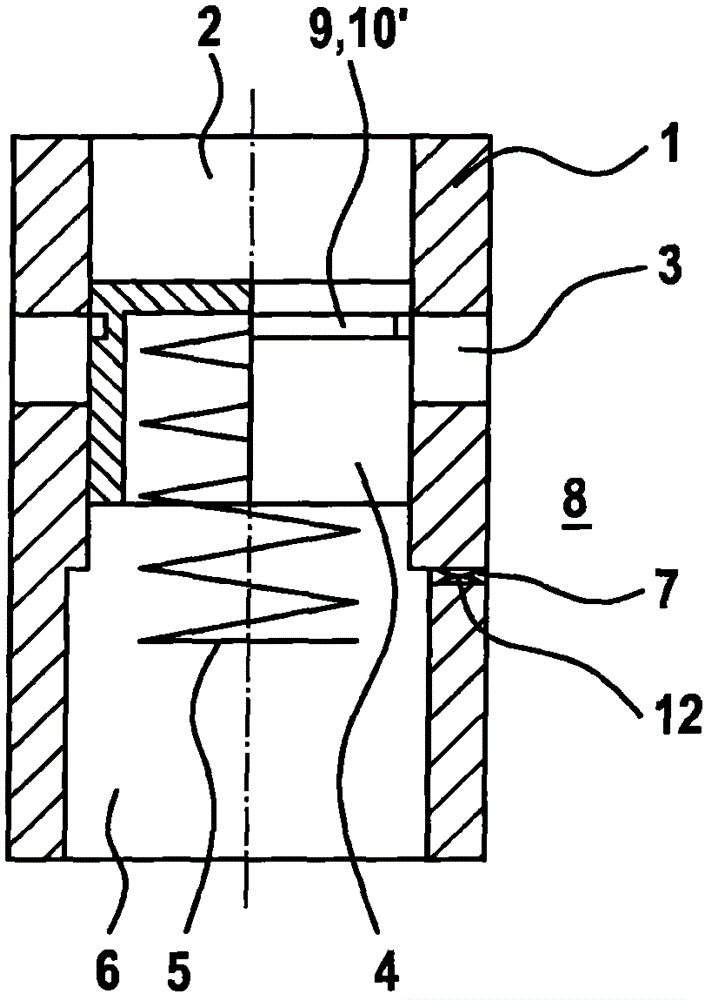

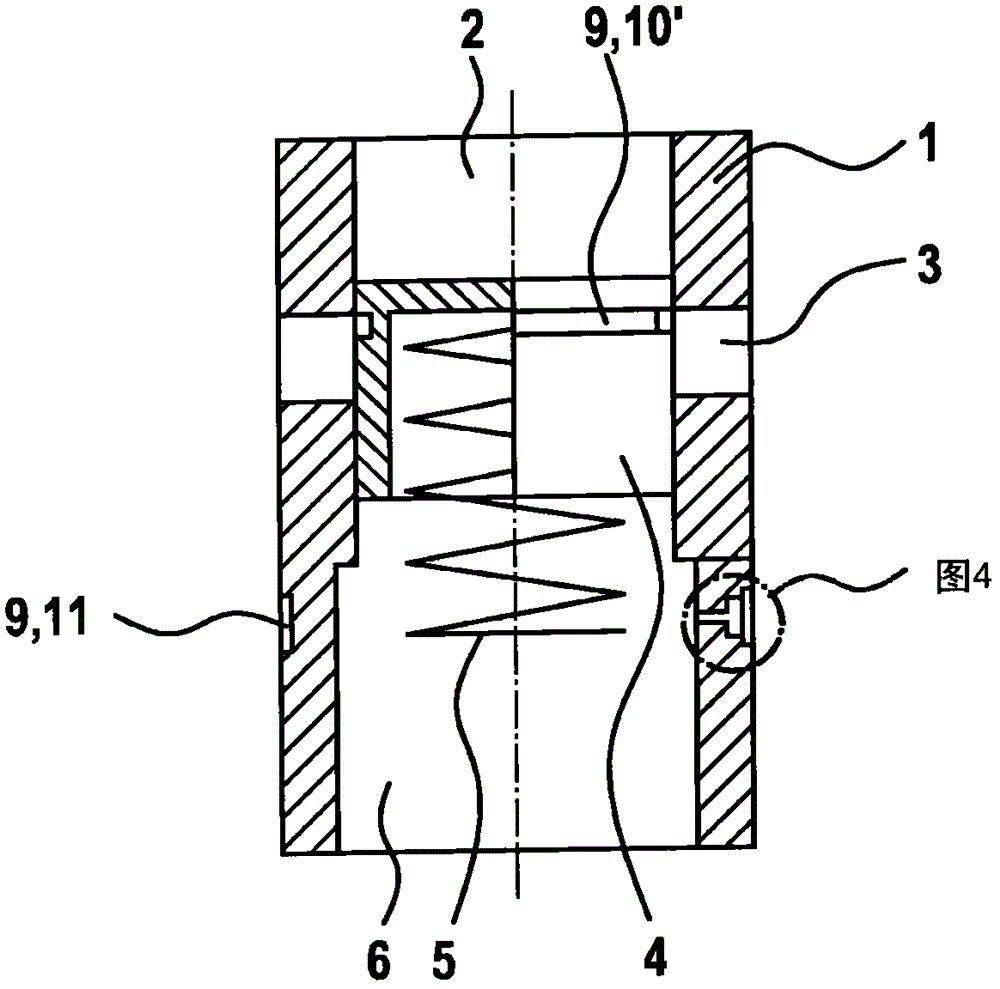

[0027] Figure 1 to Figure 3 A preferred embodiment of the overflow valve according to the invention is shown. Each of these overflow valves comprises a cylindrical valve housing 1 in which an axially displaceable piston-like valve element 4 is received such that it passes through the guide area of the valve housing 1 are axially guided. The valve housings 1 each form an inlet 2 on the end side, which can be connected to the inlet region of a high-pressure pump, not shown. Furthermore, the valve housing 1 has a radial hole serving as the outlet 3, which has a circular cross-section or any other cross-section which, when based on the axial movement of the valve element 4 (in the position of the valve element 4 Figure 1 to Figure 3 The normal position shown in is the starting point) and when a connection is established between the inlet 2 and the outlet 3, excess fuel can be conducted from the inlet area to the low-pressure area 8 via said radial holes. The axial displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com