Method for improving preset precision of rolling force of Sendzimir rolling mills in unstable-state rolling phases

A stage rolling and non-steady-state technology, applied in the direction of rolling force/roll gap control, etc., can solve the problem of large deviation of rolling force preset value, inaccurate rolling force preset, and strip thickness control accuracy Low-level problems, to achieve the effect of improving calculation accuracy, improving product quality, and improving thickness control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

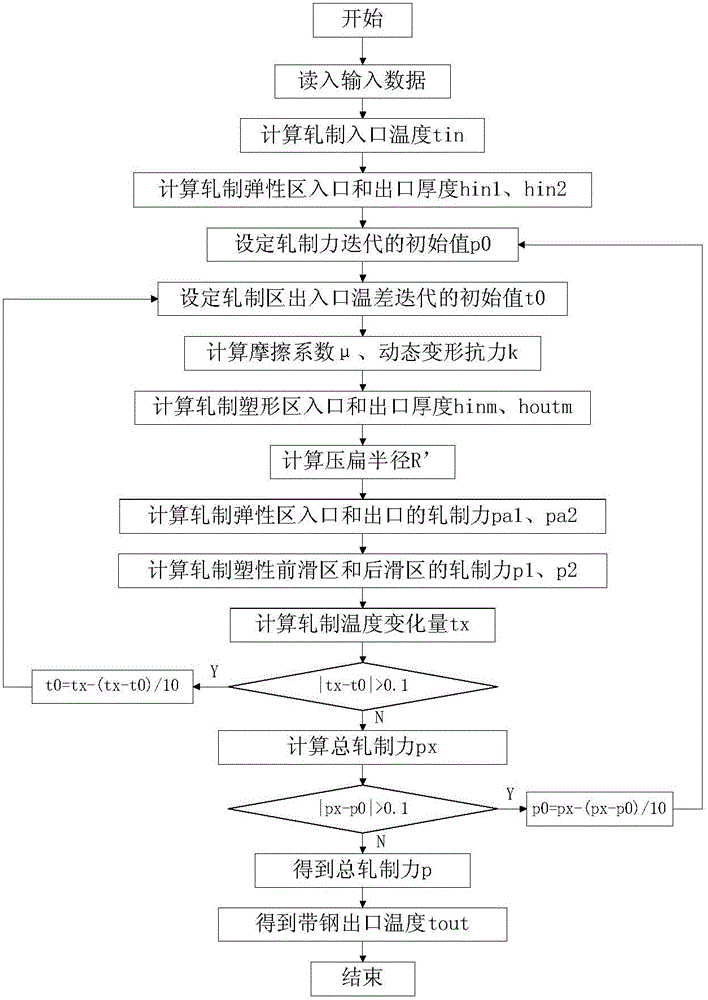

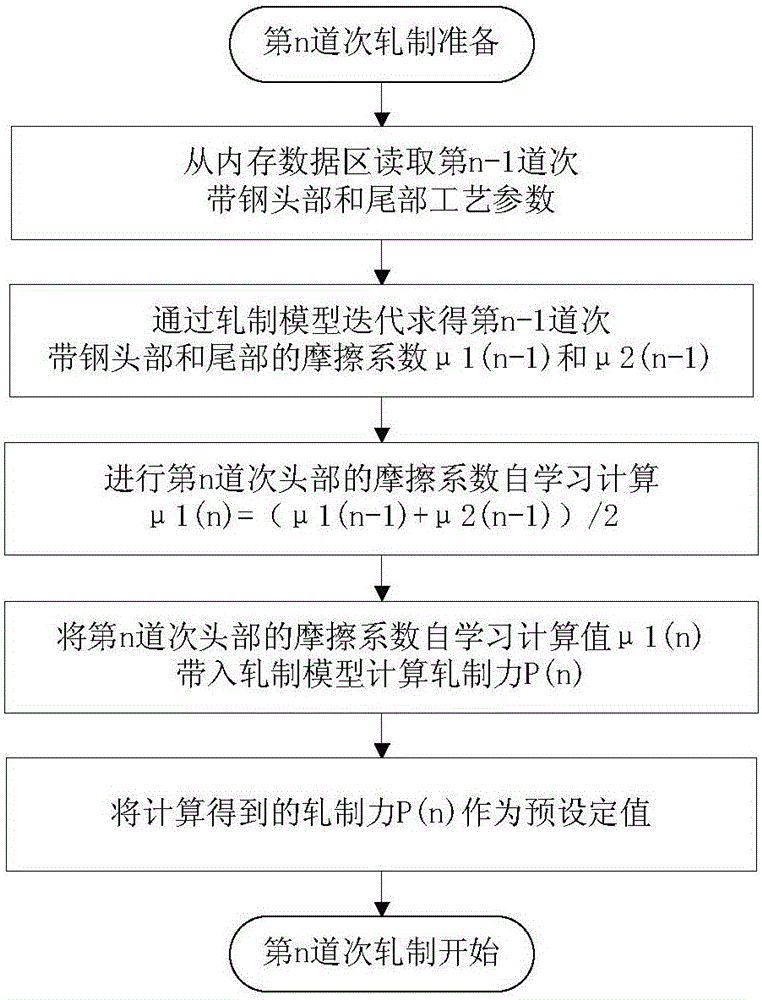

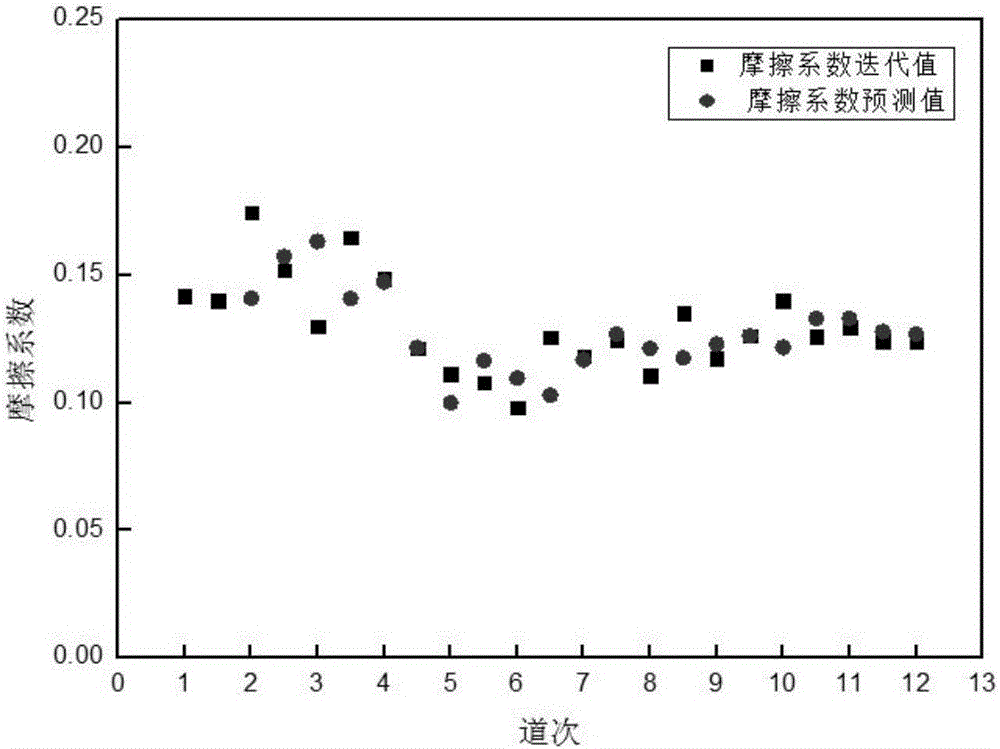

[0036] Such as figure 1 , 2 As shown, a method to improve the presetting accuracy of rolling force in the unsteady rolling stage of Sendzimir rolling mill is to first write the rolling model for calculating the rolling force, and then use the model self-learning method to adjust the friction in the rolling model The coefficient model has been revised and optimized, and the friction coefficient of the previous unsteady stage is iteratively calculated by using the measured data, which is used as the friction coefficient of the next unsteady stage to calculate the preset value of the rolling force for the next pass ; The rolling model includes the following calculation steps:

[0037] 1) Read in the input data, calculate the rolling entrance temperature tin, and calculate the entrance thickness hin1 and exit thickness hin2 of the rolling elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com