Automatic mechanical arm

An automatic machine, arm body technology, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of space occupation and poor flexibility, and achieve the effect of small space occupation, convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

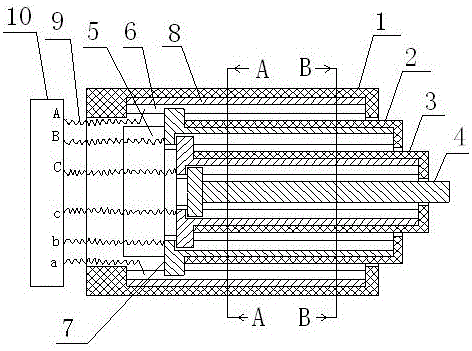

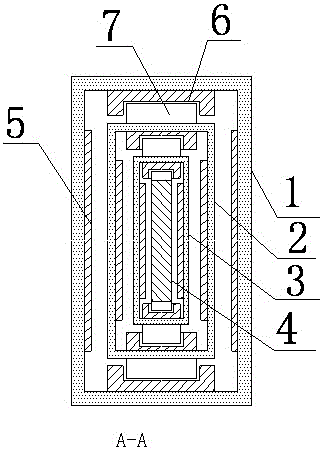

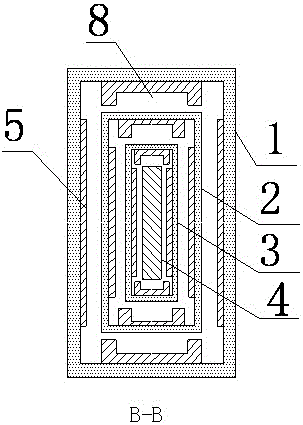

[0023] Such as figure 1 , 2 . As shown in 3, an automatic mechanical arm includes an arm body, and the arm body includes sleeves that are socketed step by step. In this embodiment, it has a structure with three levels of sleeves. A first-level casing 1, a second-level casing 2, and a third-level casing 3. The casing is a casing with a rectangular cross section. The nesting structure of the casing is similar to the pull-type retractable antenna mechanism, the casing decreases step by step, and the last stage is the smallest, and the casing should be made of insulator material.

[0024] Magnets 5 along the length direction of the casing, such as permanent magnets, are respectively arranged on the inner walls of the left and right sides of each level of casing, and the different magnetic poles of the two magnets are arranged oppositely, so that a magnet 5 perpendicular to the length direction of the casing is formed between the left and right magnets. magnetic field. Conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com