Guide column device

A technology for guiding uprights and uprights, applied in the field of main frame devices, can solve the problems of unfavorable standardized management, complicated processing and manufacturing, and large number of assembled parts, etc., and achieve the effects of shortening production cycle, reducing labor intensity, and optimizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

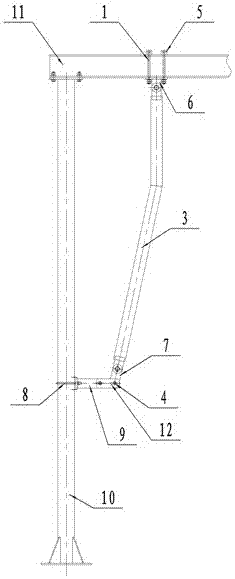

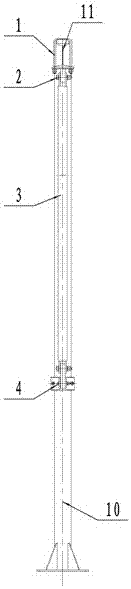

[0015] like figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a guide column device, including a main frame column 10 and a main frame beam 11; the bottom of one side of the main frame beam 11 is fixedly connected to the top of the main frame column 10, and also includes a second One U-shaped bolt 1, the first connecting bolt 2, the guide column 3, the second connecting bolt 4, the pad iron 5, the guiding hanger 6, the guiding crank arm 7, the second U-shaped bolt 8, the guiding splint 9 and the connecting hole 12 The top of the guide column 3 is movably connected with a guide hanger 6 through the first connecting bolt 2, and the bottom end of the guide column 3 is movably connected with a guide arm 7 through the first connecting bolt 2; the top of the guide hanger 6 passes through Two pad irons 5 and two first U-shaped bolts 1 are fixedly connected to the bottom of the main frame beam 11; there are two connecting holes 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com