Self-elevating wind power generation work boat

A construction ship, self-elevating technology, applied in ship construction, ship parts, special-purpose ships, etc., can solve problems such as large variable loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

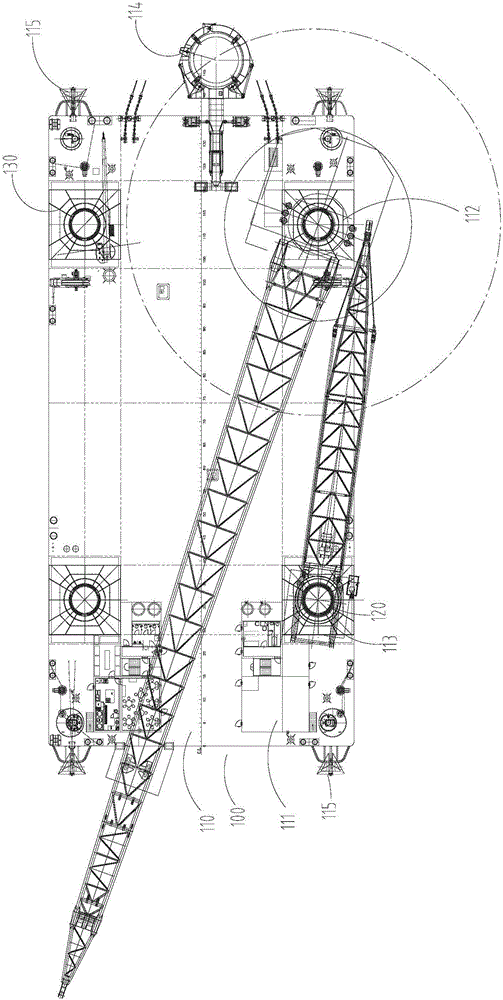

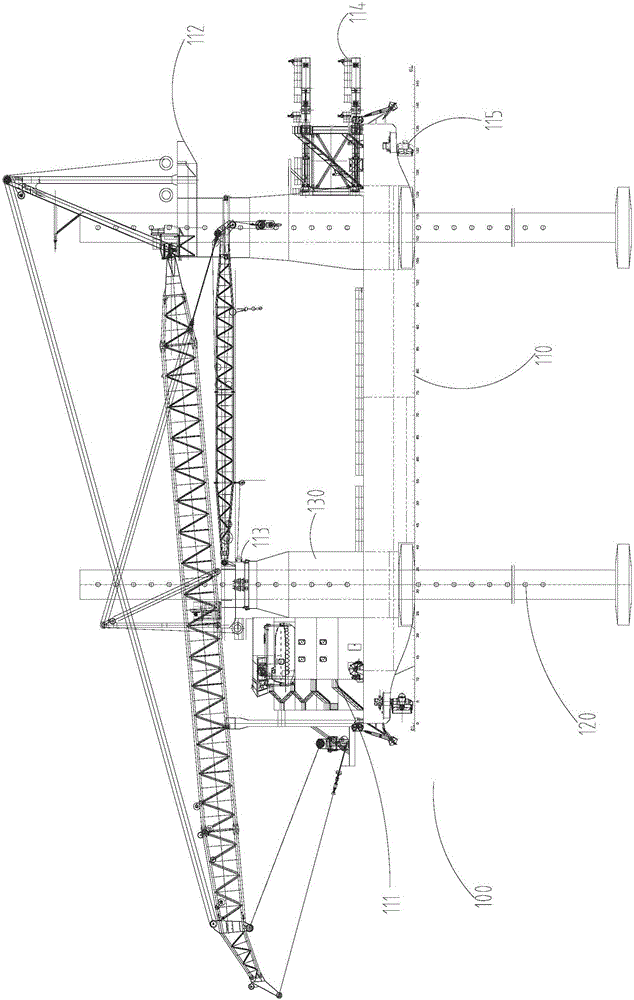

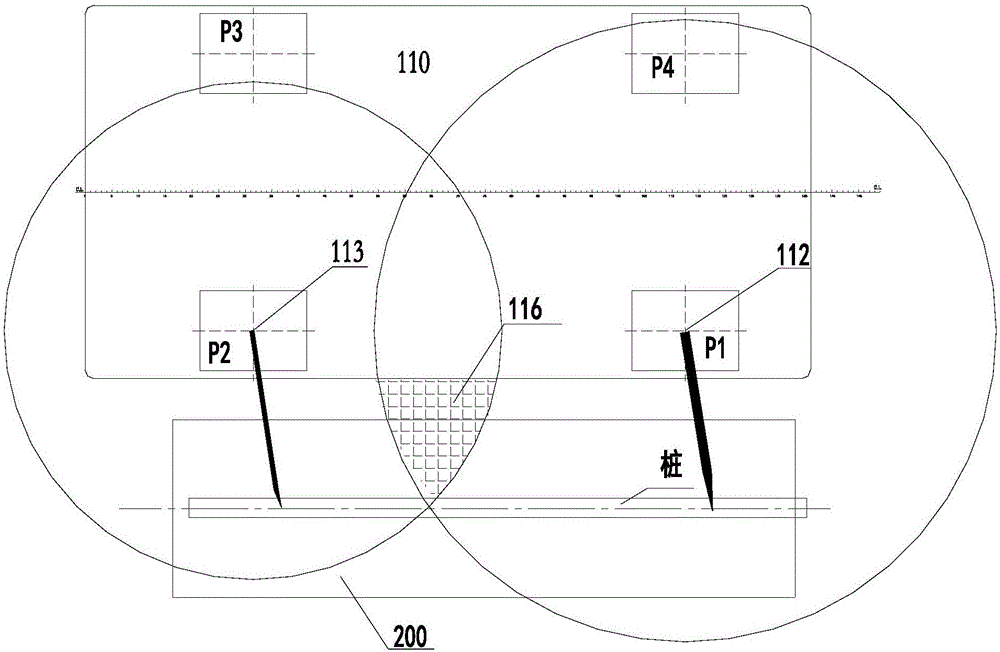

[0026] see figure 1 and figure 2 , which gives the layout scheme of the self-propelled self-elevating wind power construction ship in this example. As can be seen from the figure, the self-propelled self-elevating wind power construction ship 100 includes three parts: the hull 110, the legs 120, and the lifting system 130. Among them, the legs 120 are divided into four groups, which are symmetrically installed on the hull 110. The bow and the stern, and the two legs 120 in each group are symmetrically distributed on the left and right sides of the hull 110 . Each leg 120 cooperates with the hull 110 through the lifting system 130 to realize the lifting of the hull 110 along the leg 120 when the leg is standing or the axial lifting of the leg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com